Beyond productivity: Transform Your Smart Factory into High Yield Powerhouse

By Dave Chu

“Dear Manufacturers, What’s Stopping You to Become This?”

As of 2021, less than a hundred the global top manufacturers had earned a pristine title of becoming members of one of the most exclusive clubs, Global Lighthouse Network, the world’s most advanced factories leading the way of adoption into fourth industrial revolution technology.

“The agility and resilience of Lighthouse organizations have shown the same qualities that set them apart before the pandemic are, in fact, part of the strong foundation essential to withstanding the powerful waves of change it has brought forth,” says Francisco Betti, the Forum’s Head of Shaping the Future of Advanced Manufacturing and Production. “These qualities are what equip them to drive The Great Reset among industrials.”

While artificial intelligence & IoT fueled production facilities aimed to boost productivity while reducing cost and improving end to end customer experiences by better utilizing tech applications. The top players in the field are leveraging their production management in a completely different mindset. They’re focusing on the overall capabilities and constitutions of their operations in order to produce smarter, smoother and better. Instead of blindly chasing after ROI and productivity boost, they’re inviting their operation into the next era—Productivity of quality.

What do you mean productivity of quality?

Simply put, it’s to do more with less while achieving better quality in productivity. For instance, data ownership. This means, collecting data from your production line with complete transparency and accuracy by utilizing AI computer vision technology comparing to placing individual industrial engineers at randomly selected work stations in spurts of time. One hand you have 100% un-biased accuracy in data collection while able to trace back any point in time of your production line, and yet the other is collect by human being with a stop watch. It’s like it’s set up to fail. One, the data collected via AI are able to empower operations for predictive-strategic executive decision making, the human collected one can only be used for reference at best.

Quality of operation output from transformation into digital & technological applications doesn’t just stopped at data collection. It can also help ensure a complete takeover on quality assurance—In Process Quality Control(IPQC). A dedicated personnel is placed throughout the threshold of factory line to check on the work that’s performed on the production unit. If a defects occur, they launch into investigation & RCCA(Root Cause & Corrective Action) process. After determined the cause the next stage is to rework the unit with all the rework, scrap, material, logistics, warranty, labour costs. These are all good and all until a defective unit snuck through and went into the market.

The fallout of defects

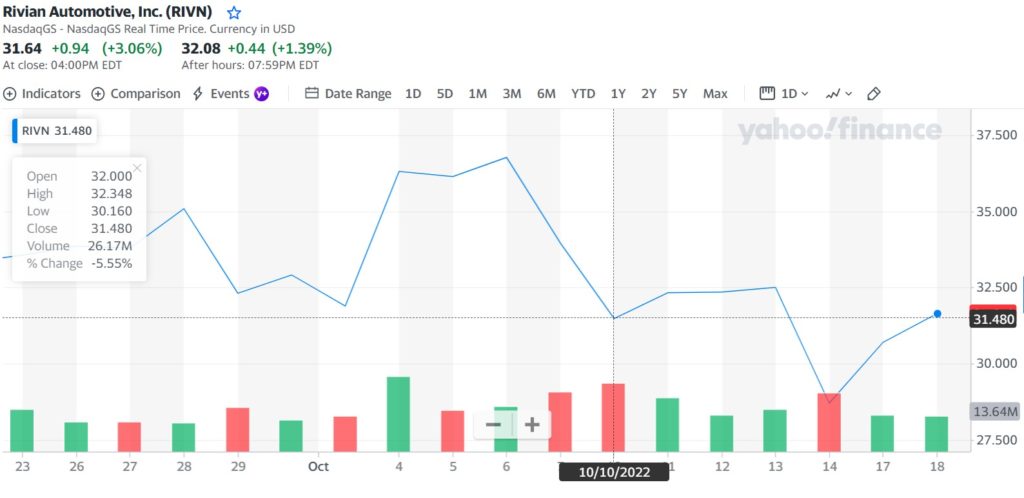

Recalling. One of the worst things can happen to your product. Just last week, California-based electric automobile startup Rivian recalled a total of 13,000 vehicles that were delivered throughout the years due to minor assembly defects involving a fastener that “may not have been sufficiently torqued,” Chief Executive Officer RJ Scaringe said in a letter to customers. This had caused Rivian a whopping dropp of 8.5% in stock prices in a day on Monday, Oct 10th. This recall involves free-of-charge services yet “the cause of the recall isn’t material”, as stated by a person familiar with this matter.

Rivian’s stock prices on Oct 10th. 2022 (Source: yahoo finance)

“The recall is a setback for Rivian, which has only recently overcome production problems and parts shortages to deliver its EVs to customers in meaningful volumes. The company also had to deal with the fallout of an embarrassing U-turn in March to raise prices on pre-orders.” Bloomberg reports. To deal with this issue, Rivian initiated a warranty recall program offering free examination on all models affected and free replacement service if qualified. There are now, additional human resources designated to provide services, support, and oversight, along with all the initial in-house rework costs that are adding on top.

Transform your factory into high yield, high quality output powerhouse.

All these, however, are preventable by implementing advanced tech solutions into in process quality control. For instance, by implementing IoT devices, factories are able to extract efficient data from screwdrivers, barcode scanner, agv and more. While where certain procedure that’s undetectable via IoT tools, production can implement computer vision AI to provide clarity and supervision on those key work station. Combining with real-time notifications and alert system of actionable insight. Line managers and factory heads are able to monitor their production line knowing every single units passing by are met with the highest quality standard.

PowerArena is an AI vision that lives in your production line, capturing human motions from each workstation using computer vision. Bringing clarity through unprecedented amounts of data from your workstation. Visualizing the hidden inefficiencies and provide the most accurate information of your production line down to the minutes. With integration using manufacturing tools PowerArena’s AI is able to achieve highest tier in-process quality control that’s applicable in any first-class quality output production.

[Click here to request a demo on how PowerArena’s AI vision helps electric vehicle production achieve an average above 99.5% quality output.]

Source: https://www.bloomberg.com/news/articles/2022-10-10/rivian-shares-fall-after-13-000-vehicles-recalled-to-check-nut / https://www.mckinsey.com/~/media/McKinsey/Business

Read More:

From Low-code to No-code: An AI democratization

Beyound Productivity: The 4 Aspects of Lean Budget Refinement