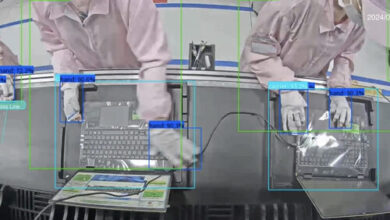

Human Operation Platform powered by AI vision

Shining a light on the human factor

Over 60% of manufacturing mistakes are still human related.

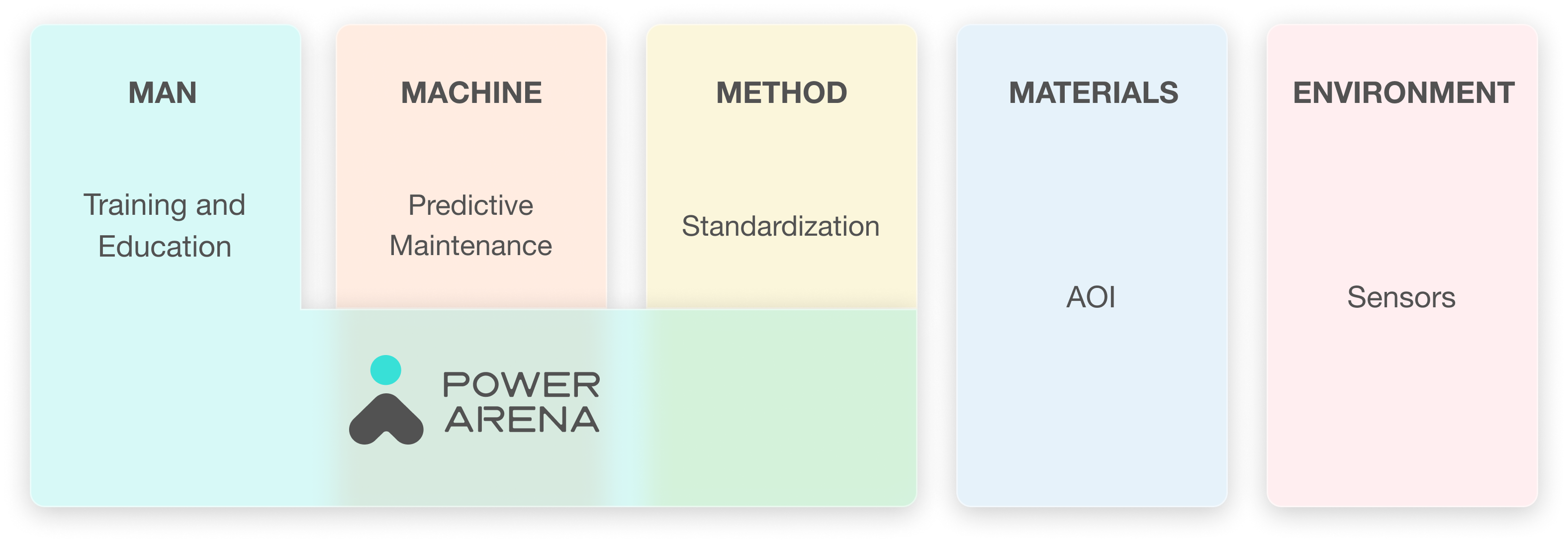

From the 4M1E perspective, while there are good solutions for problems related to machines, materials and environment, man and method, especially the manual operations on assembly lines, are still difficult to solve.

Until now. PowerArena’s HOP monitor operator actions, and instantly alerts to any SOP non-compliance.

Tested and proven with industry-leading

manufacturers

HOP methodically delivers outsized value to:

-

Global management

Your factory operations in the palm of your hand

Unprecedented transparency for your global production pipeline with the clarity of AI vision modeling, immediate insight and real-time transparency.

Read more -

Factory managers

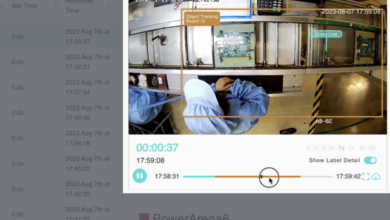

Actionable insights for improved production and zero blindspots

Optimize your production environment with full high value metrics, instant replay and real-time alerts. Get higher productivity, quality and SOP compliance safety.

Read more -

Industrial engineers

Work smarter, easier and faster with AI power

Your tireless digital assistant oversees production 24/7, saving you time in your quest for continuous improvement. Easily slot a complete solution into your production lines for impressive results fast.

Read more

Every aspect of PowerArena’s industry-leading AI is designed to be deeply integrated to facilitate high variety manufacturing.

Combining computer vision with AI motion detection provides accurate data extraction to thousands of EMS providers – all while undergoing maximum stress trial and error testing.

An essential productivity upgrade

for every line

Data ownership

Productivity

Quality

Case Studies

PowerArena HOP has already delivered impressive ROI in a factory similar to yours

These case studies cover only a fraction of PowerArena HOP installations. Tell us about your situation and we’ll share relevant data and details.