Line balancing is critical in manufacturing operations, it has been an index to determine the effectiveness of production lines. For manufacturing professionals, to achieve line balancing is to lower production cost, waste and improve productivity.

As stated by Lean Math, a lack of line balance routinely causes the waste of waiting or overproduction. It can also prompt over-processing during which operators, rather than engage in the blatant waste of waiting, conduct “apparent work.” Line imbalance is an enemy of continuous flow.

One of the main factors in achieving line balancing is to identify bottlenecks and tackle it accordingly, and it requires data.

Traditionally, industrial engineers collect the data by using a stopwatch, and log the records on papers, in short, it was done manually and very time consuming. Study has shown that by collecting data this way, they are only able to capture about 15 minutes worth of data per month, which translates to 0.03% of the data.

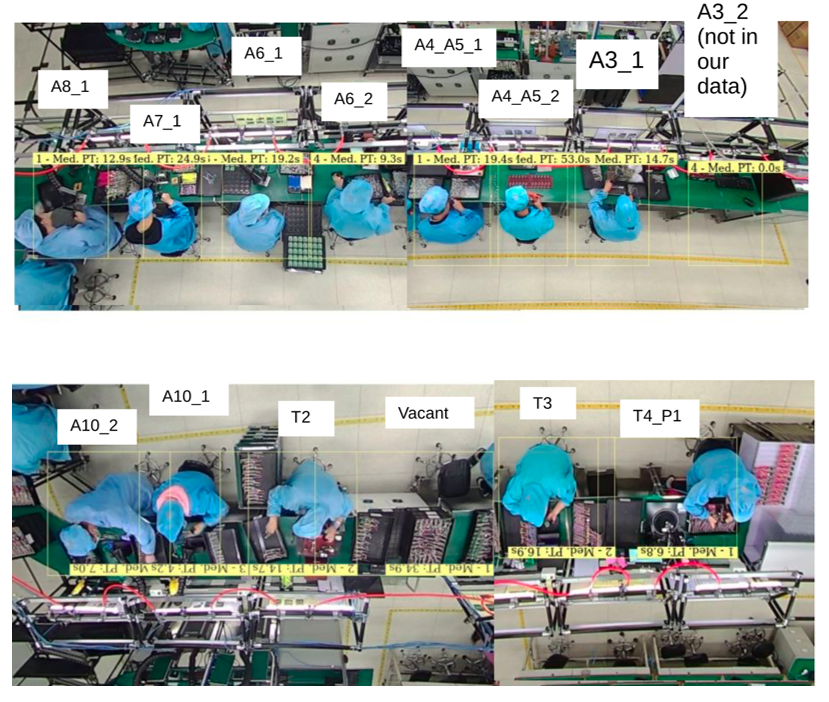

And this is how PowerArena’s AI Line Balancer comes in. Combining video stream and AI, PowerArena analyzed videos of production lines to collect real-time cycle time data of each workstation.

As in the above video, we log the process time and cycle time in each workstation in real time, PowerArena AI analyzes the operation and calculates the time step required by the operators.

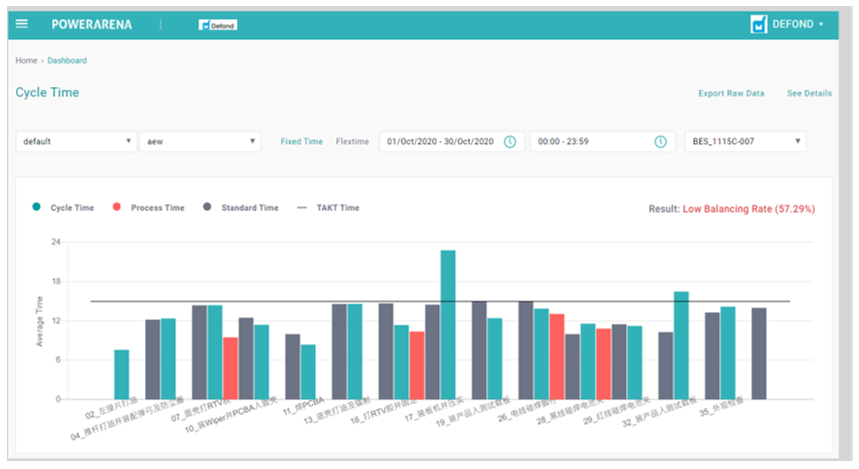

The collected data helps to identify the bottleneck of the production lines as well as where in the lines were found unbalanced, enabling industrial engineers to conduct root cause analysis and adjust the production line accordingly to achieve line balancing.

Click here to read the case study on how we helped a top 5 EMS factory in achieving a 5% improvement in UPH under 4 weeks with this tool.