Introduction

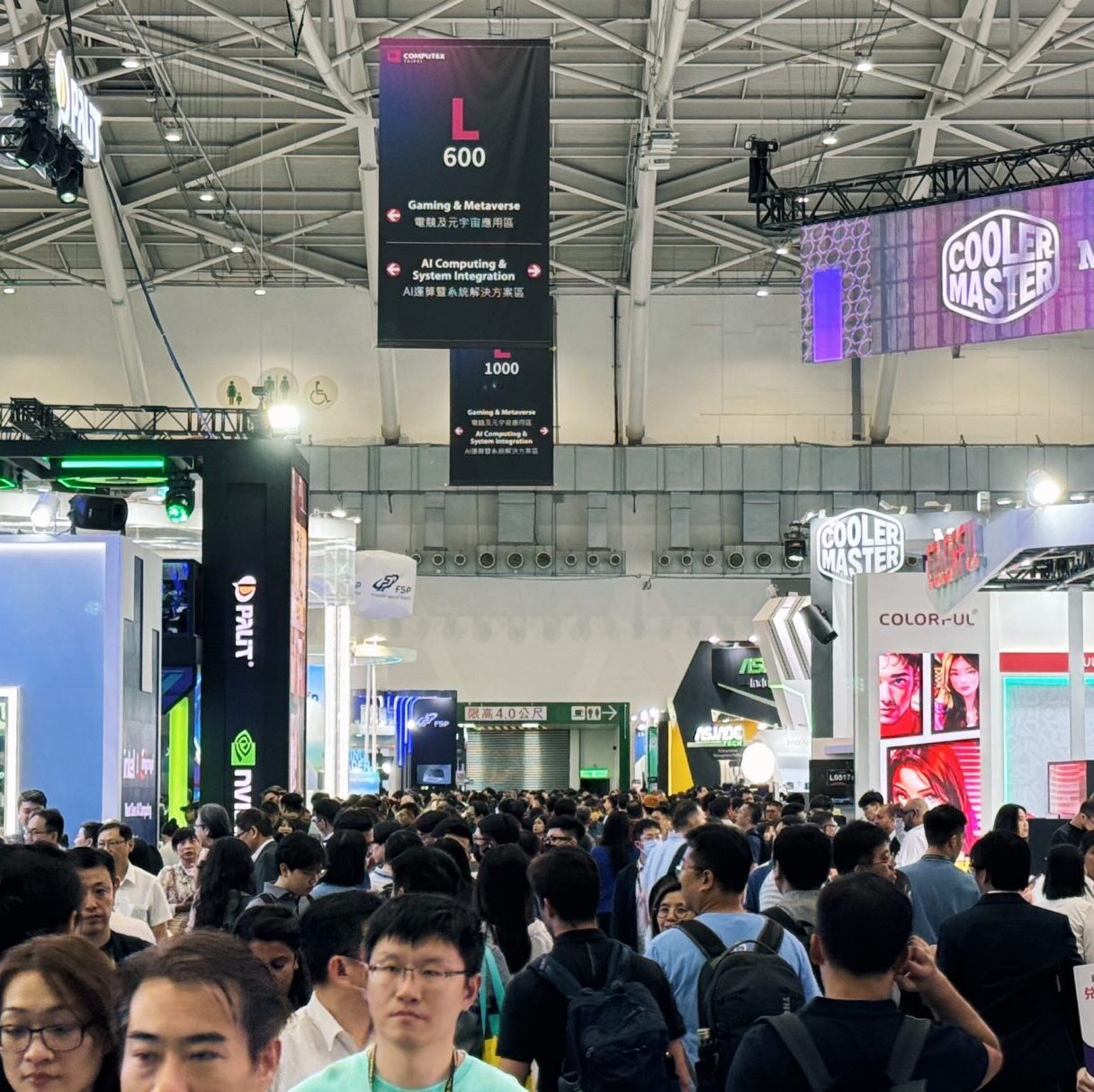

The “AI EXPO Taiwan 2024” attracted global leaders and experts from industry, government, and academia over a three-day event, showcasing the latest applications and future trends of AI technology in various fields.

With 250 companies and brands, 60 universities and AI research centers, and 56 startups participating, the event saw nearly 25,000 registrants. It brought together leading AI developers and talents from various sectors, highlighting the ever-growing momentum of AI trends.

We have distilled the insights from industry experts in the first half of 2024 into several key points.

Highlights from Expert Keynotes

AI Everywhere. Manufacturing AI Terminal Applications.

ST Liew, Vice President and President of Qualcomm Taiwan and South East Asia , Qualcomm Technologies Inc.

The explosive growth of generative AI over the past couple of years has shown that AI is everywhere.

Previously, AI applications were concentrated in specific areas such as traditional AI in devices like smartphones, cameras, and voice assistants. However, with the advent of generative AI, the scope of AI applications has greatly expanded, permeating various industries and daily life. Liew stated:

“For the next ten to twenty years, it will be AI Everywhere.”

Liew emphasized that the optimal AI experience is provided by hybrid AI systems, which combine AI functionalities on end devices with the computational power of the cloud. This not only saves costs and improves efficiency but also enhances privacy protection and personalized experiences. AI applications on end devices offer low cost, high performance, and strong reliability advantages. These devices include smartphones, personal computers, AR/VR glasses, and in-car systems. Generative AI applications can cover text, images, videos, and code generation, demonstrating significant potential in both everyday life and industrial applications. One can imagine that in the future, there will be an increasing number of terminal AI deployments in frontline manufacturing. These AI systems will assist on-site personnel in quickly obtaining production information, tracking production status in real-time, and ensuring sustained production capacity, encompassing various potential applications.

The value of the AI market is immense and challenging to estimate precisely. According to McKinsey’s comprehensive analysis of AI in business operations, R&D, and engineering, the value of the AI industry could reach $7.9 trillion, indicating its vast potential.

Data is the New Oil. Three Focuses for Manufacturers.

Robert Wang, Managing Director, HK& TW, Amazon Web Services

“Data is the new oil.”

Its value lies in its effective extraction and utilization.

Wang emphasized that to leverage this new oil, data security is the primary concern. Without strong data security measures, the value of any data is moot. Addressing the issue of data silos is the second key point. Data scattered across different departments and systems, difficult to integrate and utilize, is a major obstacle to data monetization. Through data lakes, companies can integrate old and new data to improve data application efficiency. The third key point is data democratization, meaning breaking down information asymmetry and ensuring data is available to those who need it. These three aspects combined build a successful enterprise data governance capability.

Mastering the new oil of data from three aspects: 1. Data Security 2. Data Silos 3. Data Democratization

AWS’s “new oil” combined with generative AI has multiple applications. Wang cited Amazon’s internal use case, where setting up new physical locations can quickly retrieve detailed local regulations through a robust built-in database. Additionally, Amazon Prime Video uses generative AI to dynamically replace ad content in videos, increasing profitability.

Thinking, Fast and Slow. AI Computation Offloading.

Bor-Sung Liang, Senior Director at MediaTek

Future AI inference applications will move to end devices like smartphones and personal computers to reduce data center energy consumption and increase computational efficiency, but some issues remain to be solved.

AI inference requires rapid response to user requests, with application complexity and changes in user volume and frequency affecting workload. To run AI models on end devices, considerations include model size and memory requirements. Typically, smartphone memory ranges from 4GB to 24GB, and models should be controlled below 7 billion parameters to ensure effective operation. Unlike data centers that can scale GPUs to boost computing power, memory bandwidth on smartphones is also a concern.

Future AI computation = Edge (fast thinking, responding to frontline user needs) + Cloud (slow thinking, performing high-intensity computations)

Liang compared it to the human brain’s “fast thinking” and “slow thinking” systems, suggesting that future AI computation will rely on fast thinking at the edge for intuitive, quick responses, and high-intensity, slow thinking computations handled by the cloud. This collaboration between edge billion-level models and cloud trillion-level models can balance computational efficiency and user experience, meeting increasingly complex multimodal application demands.

AI multimodal applications for manufacturing management can integrate both image and text technologies. For the image part, cameras installed at workstations can transmit visual information, enabling visual models to recognize actions. When combined with text models, this setup allows managers to input commands and receive AI-driven analysis and recommendations on worker behavior images. This integration aids management in making more informed decisions.

AI for Risk Management. Manufacturers are falling behind.

Elaine Wen, SEO at Artificial Intelligence Foundation Taiwan

Wen shared the “2023 Taiwan Industrial AI Survey” report, revealing that companies still face numerous challenges, with a Matthew Effect present, meaning the strong get stronger, and the weak get weaker. Only a few companies truly benefit from generative AI, while most are still exploring suitable AI application scenarios.

The survey showed that in manufacturing and government sectors, up to 74.1% are still in the early “Unknowing AI” stage, where many employees may have heard of AI but lack relevant knowledge and understanding of how to apply it. 60.5% indicated that their companies are still planning or have never applied any AI technology, and 58% believe their companies lack relevant technical talent, with these figures higher than the overall industry average.

Facing future changes, Wen suggested that companies start from demand, ensuring that AI can bring real value, and consider geopolitical, energy, and macroeconomic factors. Finally, the perspective of AI as a cost or investment should shift to seeing AI as a risk management tool, becoming an integral part of operational risk governance.

(Source: AI Technology Foundation (2024). Taiwan Industrial AI Survey, AI Competition under the Generative AI Wave.)

So Manufacturers, What About the Future of AI?

Generative AI tools have lowered the threshold for using AI, while also highlighting the urgency for companies to adopt new technologies. However, the reality is that the overall AI adoption index in industries remains low. To truly catch this technological wave, it still relies on the strategic planning of organizational leadership.

Currently, the overall understanding of AI among employees is low, with more than half of companies unsure if they have AI engineers, and lacking training plans. This should serve as a major warning to companies, prompting them to invest resources in training internal IT and OT experts, while also seeking external AI experts to quickly gain professional knowledge and maximize AI transformation efficiency.

Successful AI application = External AI experts + Internal IT/OT field experts

The progression of enterprise AI development from Unknowing AI, Conscious AI, Ready AI to Scaling AI aims to ultimately enable companies to transfer AI across different project scenarios, achieving scaled mature applications.

Starting with One Workstation, Advancing Towards Scaling AI

PowerArena’s Human Operation Platform (HOP) assists manufacturers in gradually utilizing AI, starting with installing a camera at one workstation. Using AI vision to collect worker behavior information, it examines operation time, action sequences, tool usage, etc., enhancing production management, and achieving goals of production efficiency optimization and product quality improvement.

HOP can connect with various IoT and factory MES systems, integrating AI image information with various equipment information, solving the problem of data fragmentation in traditional management models, without worrying about data silos. Detailed production data is clearly presented on the management interface, convenient for remote management. The digital SOP function can also immediately alert on-site personnel of operational anomalies, transmitting information in real-time to operators, IE, line leaders, plant managers, and senior managers, all benefiting from AI analysis of real-time data.

Back to top