Increase productivity & profits for Electronics Manufacturers

Electronic manufacturers get more productive factories, transparent production line, with the ability to ramp up production in new factories

Three out of five EMS leaders have integrated PowerArena AI vision into their global operations.

PowerArena reveals EMS assembly line inefficiencies, eliminates errors and raises output

Factories get located and relocated all around the world. Many struggle to stay competitive by controlling costs, raising efficiency and maintaining quality. PowerArena HOP powered by AI vision and analysis systems deliver quality improvements, cost effectiveness and make it easier to relocate production to new factories.

Relief for EMS pain points

Case Studies

PowerArena HOP has already delivered impressive ROI in a factory similar to yours

These case studies cover only a fraction of PowerArena HOP installations. Tell us about your situation and we’ll share relevant data and details.

More Applications

Digital

Station

Digital Station

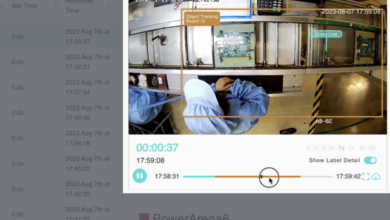

- Reduce downtime

- Monitor the interaction between workers and machines

- Detect long delay and assist root cause analysis

- Improve machines overall equipment effectiveness (OEE)

AI Line

Balancing

AI Line Balancing

- Streamline workflow productivity

- Identify opaque and complex bottlenecks

- Workflow metrics that visualize the factory floor

- Empower the workforce by strengthening teamwork and gaining productivity

AI

Poka Yoke

AIPoka Yoke

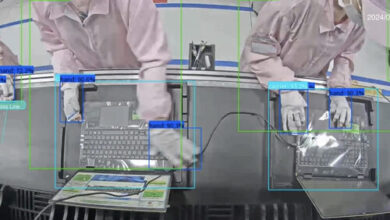

- Maintain standard operating procedure compliance

- Detect and alert workers who skipped work steps

- Ensure quality through SOP compliance

- Customizable SOP detection software