The industrial engineer’s superpower – factory floor AI vision.

PowerArena Human Operation Platform (HOP) powered by AI vision delivers real value.

No More Clipboards & Stopwatches. It's AI now.

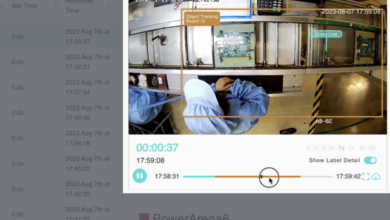

Automated individual workstation data collection empowers manufacturers with precise, real-time insights. When things go wrong, real-time alerts provide instant understanding of the issue, enabling swift corrective actions that minimize disruptions.

Pinpoint When and Where with Track & Trace.

Track and trace capabilities allow manufacturers to pinpoint any point in time of production, ensuring complete visibility. This transparency supports higher quality standards and reduces errors in the manufacturing process.

Build Your Golden Line. Then Scale.

Simplifying SOP golden line development and replication becomes effortless with PowerArena’s HOP, ensuring consistent quality and efficiency across production lines. HOP enhances operational agility and scalability, supporting long-term growth.

Cut 60% of industrial engineer workload.

Relief for your pain points.

Main applications

Digital

Station

Digital Station

- Reduce downtime

- Monitor the interaction between workers and machines

- Detect long delay and assist root cause analysis

- Improve machines overall equipment effectiveness (OEE)

AI Line

Balancing

AI Line Balancing

- Streamline workflow productivity

- Identify opaque and complex bottlenecks

- Workflow metrics that visualize the factory floor

- Empower the workforce by strengthening teamwork and gaining productivity

AI

Poka Yoke

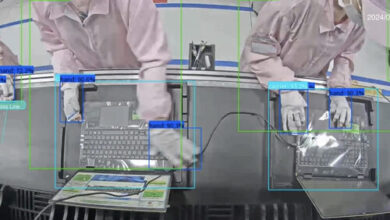

AI Poka Yoke

- Maintain standard operating procedure compliance

- Detect and alert workers who skipped work steps

- Ensure quality through SOP compliance

- Customizable SOP detection software

Case Studies

PowerArena HOP has already delivered impressive ROI in a factory similar to yours

These case studies cover only a fraction of PowerArena HOP installations. Tell us about your situation and we’ll share relevant data and details.