Get more from your production lines with AI Line Balancing.

Time is of the essence.

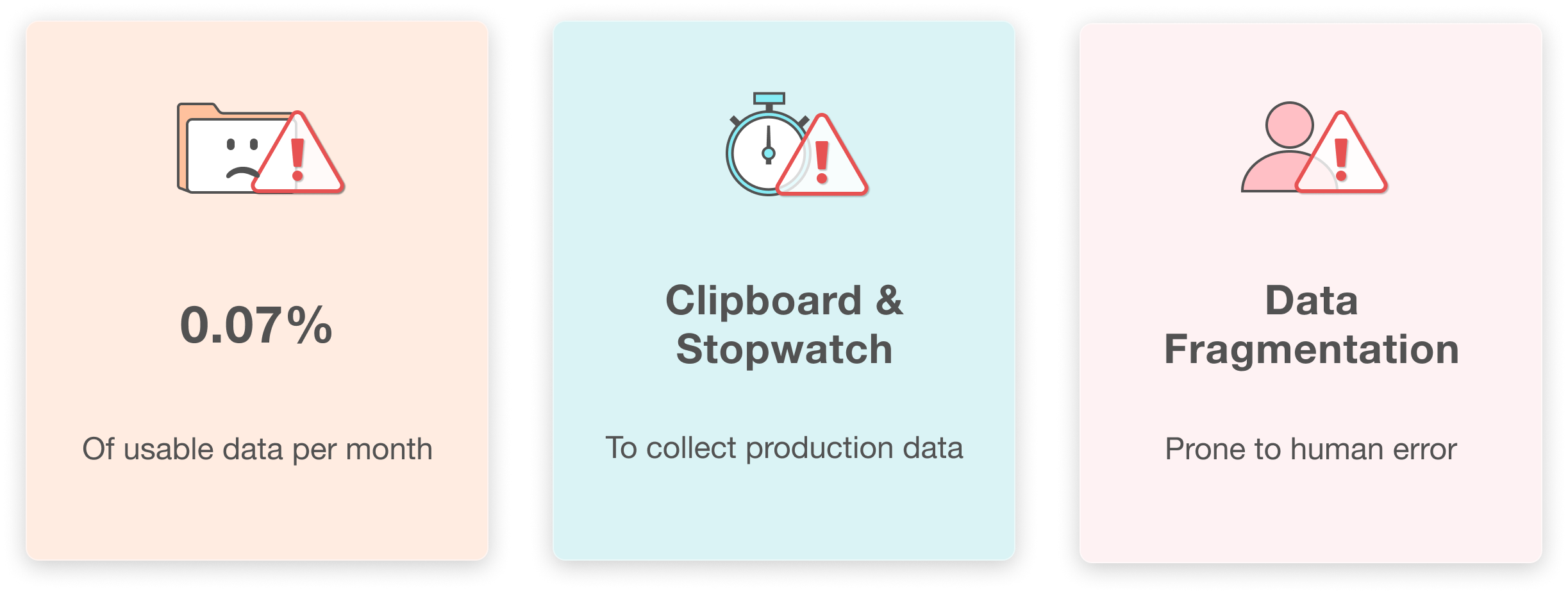

Nowadays, Line Balancing done by human can be an efficiency killer. From the use of clipboard and stopwatch to record operator activity. To gaining only 30 minutes of usable data in an entire month of work. On top of that, this data can be fragmented, biased and distorted by human error.

Introducing

AI Line balancing

24/7 AI Capture. Precision Data Report. Now with AI Auto Root Cause.

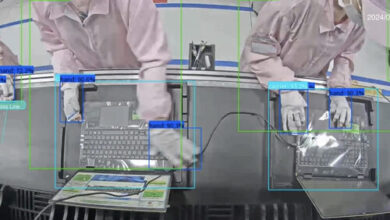

HOP AI Line Balancing capture and record every detail of conveyor, workstation and operator activity around the clock. The result is high quantities of high quality data giving in-depth views of assembly line activities.

24/7 Production Line Data Collection.

With exceptional visibility into production line processes. HOP applies AI Vision to capture and record every detail of conveyor, workstation and operator activity around the clock. The video feed data is combined with IoT data.

Supercharge Industrial Engineers.

HOP are able to capture actual cycle time to reveal the actual cause of production irregularities. AI Vision can even identify working process time & idle time along with realtime alert to supercharge Industrial Engineer’s capabilities to visualize factory production.

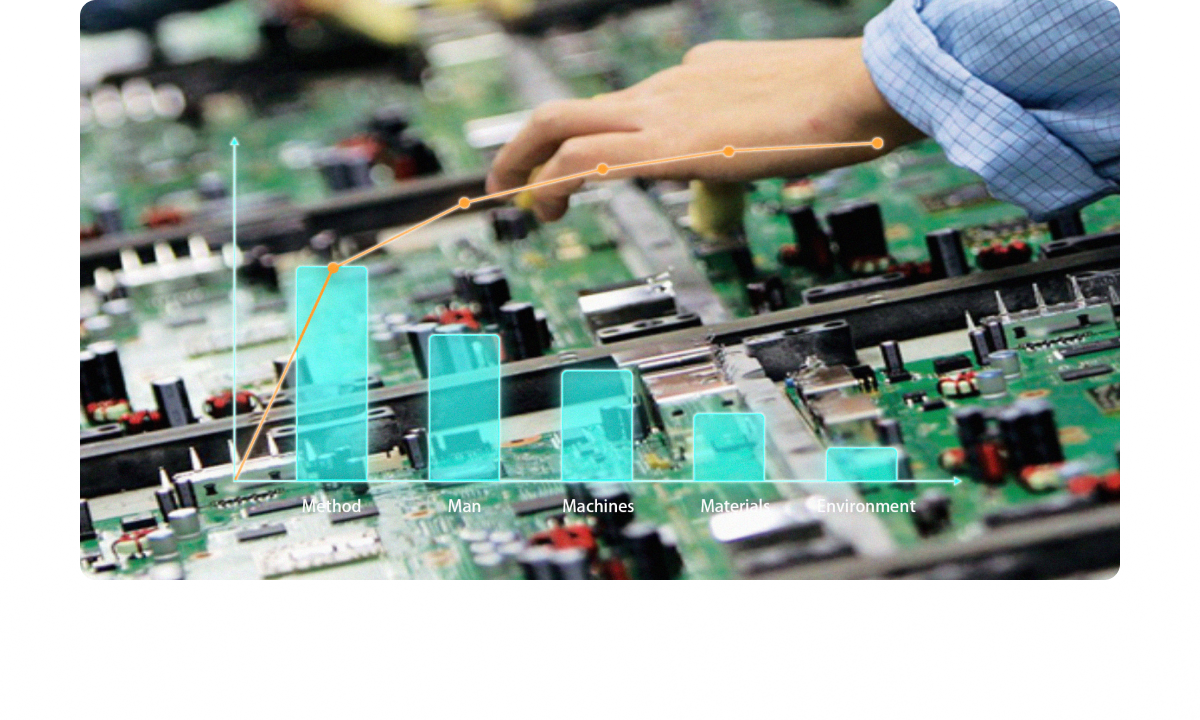

Root Cause Analysis & Auto Root Cause Detection.

HOP applies machine learning algorithms to identify exactly how a production line can be improved. The process narrows down on the bottle neck quickly. Effectively raising human assembly line productivity. Ongoing testing and optimizing delivers exceptional assembly line production gains.

HOP AI Line Balancing

Case Studies

PowerArena HOP has already delivered impressive ROI in a factory similar to yours.

These case studies cover only a fraction of PowerArena HOP installations. Tell us about your situation and we’ll share relevant data and details.

Main Applications

Digital

Station

Digital Station

- Reduce downtime

- Monitor the interaction between workers and machines

- Detect long delay and assist root cause analysis

- Improve machines overall equipment effectiveness (OEE)

AI Line

Balancing

AI Line Balancing

- Streamline workflow productivity

- Identify opaque and complex bottlenecks

- Workflow metrics that visualize the factory floor

- Empower the workforce by strengthening teamwork and gaining productivity

AI

Poka Yoke

AI Poka Yoke

- Maintain standard operating procedure compliance

- Detect and alert workers who skipped work steps

- Ensure quality through SOP compliance

- Customizable SOP detection software