By Sursha Wu

In today’s manufacturing world, staying competitive means staying smart. More companies are turning to AI to boost efficiency, reduce errors, and gain better control of operations. Among the many AI tools available, AI computer vision stands out as one of the most powerful.

The global AI vision market will grow from $34.1 billion in 2024 to $93.73 billion by 2028, with a CAGR of approximately 28.8%.

This growth shows that businesses are confident in AI vision technology and are seeing real results from its use.

In this blog, we’ll break down how AI computer vision works, where it’s used, and why it’s transforming factories into intelligent, future-ready operations.

How does AI vision improve the EMS production line?

What is AI Vision?

AI computer vision allows machines to “see”, “understand”, and “interpret” image/video data.

By analyzing image/video from cameras on the production line, AI computer vision can track human actions, detect product defects, and verify that workers follow standard operating procedures(SOPs).

It is like giving a machine the ability to see, and also the intelligence to understand what it is seeing.

Labeling example

How AI computer vision works

The role of deep learning

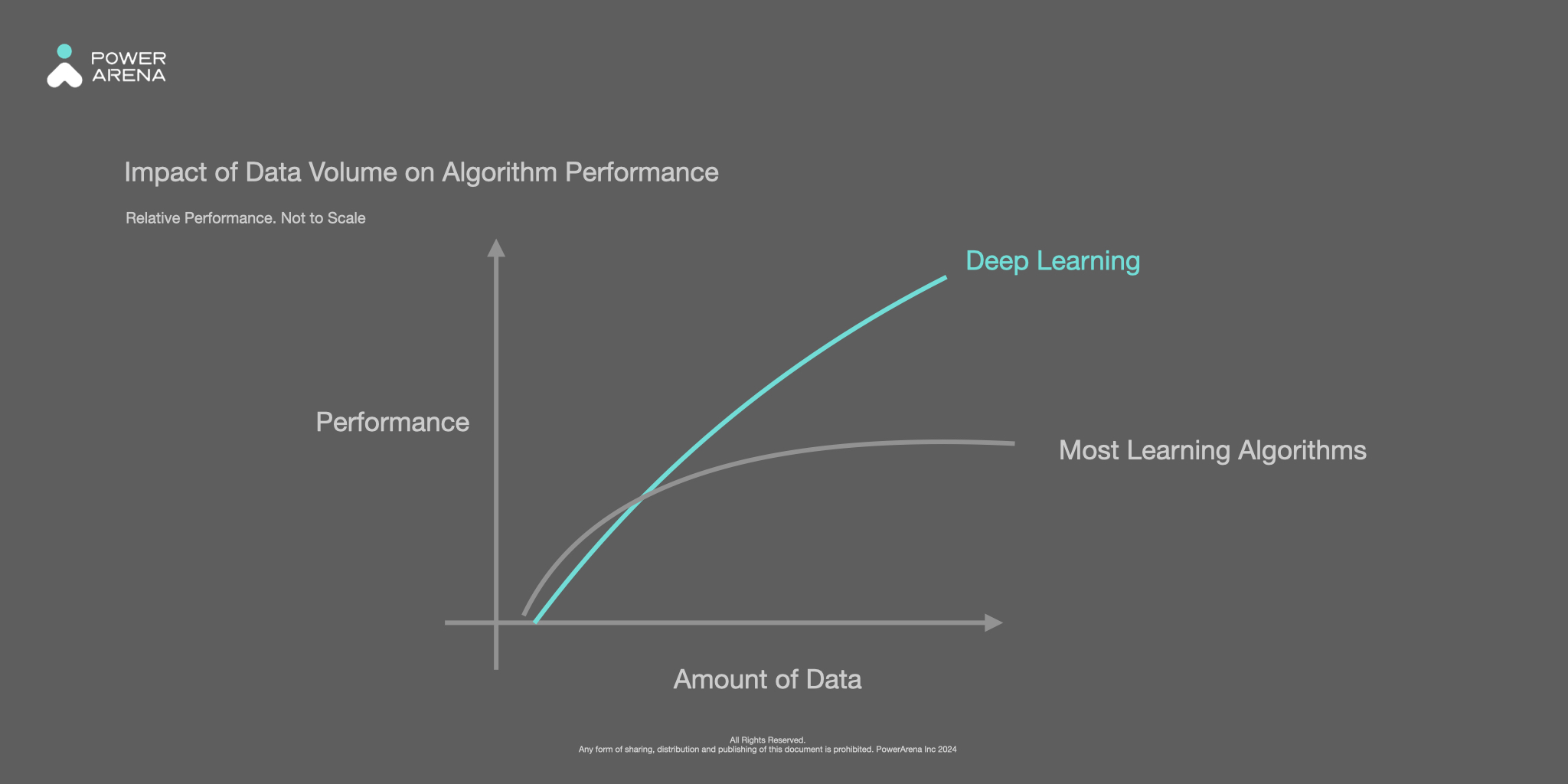

Traditional algorithms often reach a point where adding more data does not improve accuracy. Deep learning solves this problem.

Deep learning overcomes this barrier.

Impact of Data Volume on Algorithm Performance

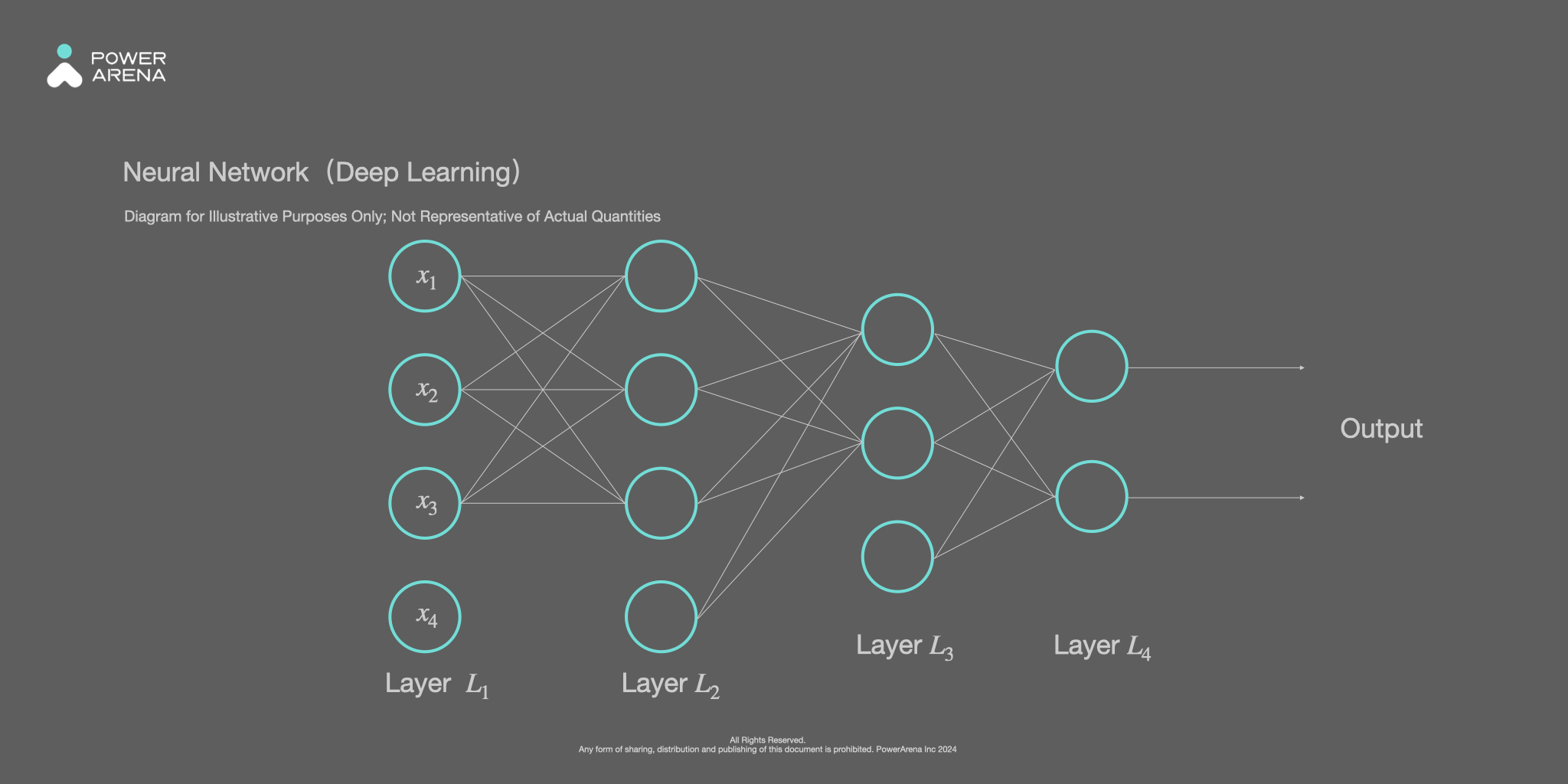

Deep learning uses neural networks that are inspired by the human brain. These networks are built with layers, where each layer processes information and passes it to the next. This layered structure helps the model understand patterns in images that are too complex for traditional methods.

This “layered approach” allows deep learning to handle complex and large-scale data more effectively.

Neural Network (Deep Learning)

To train a deep learning model, we provide labeled images.

For example, we labeled one image as “cat” and another as “dog.” After seeing enough examples, the AI vision model becomes able to recognize new images on its own with high accuracy.

Labeling example

AI computer vision applications

Self-driving Vehicles

AI vision helps vehicles identify pedestrians, traffic lights, and road signs. It allows real-time navigation and collision prevention, making autonomous driving safer and more reliable.

Medical Imaging

Doctors use AI to analyze X-rays, CT scans, and MRIs. This improves the speed and accuracy of diagnosis while reducing the burden on medical staff.

Retail and Smart Stores

AI vision can identify the age, gender, and behavior of shoppers. This helps retailers improve store layouts and deliver targeted promotions. Amazon Go is one example where AI vision is used for automated checkout.

Smart Cities

Cities use AI vision for traffic monitoring, safety surveillance, and rule enforcement. In Singapore, smart traffic systems analyze video data to manage congestion and improve public safety.

Airports and Travel Security

Major airports such as Heathrow and Changi use AI vision to automate baggage tracking and facial recognition at boarding gates, improving both speed and security.

Smart Factory Management

In manufacturing, AI computer vision captures and analyzes production video in real time.

With 24/7 continuous monitoring, AI computer vision system collects and analyzes critical production data, like cycle time, takt time, and process time, enabling factories to improve quality and efficiency automatically.

PowerArena’s AI vision accurately tracks operator actions and objects, ensuring full compliance with standard operating procedures (SOPs).

Also, unlike traditional AOI systems, AI vision offers greater flexibility. It not only recognizes people, objects, and actions, but also actively detects improper movements or assembly errors. This helps prevent incorrect processes from continuing and provides nearly 100% in-process quality control while ensuring SOP compliance.

AI computer vision examples

AI computer vision has a wide range of applications across the manufacturing sector. Below are some of the most impactful use cases.

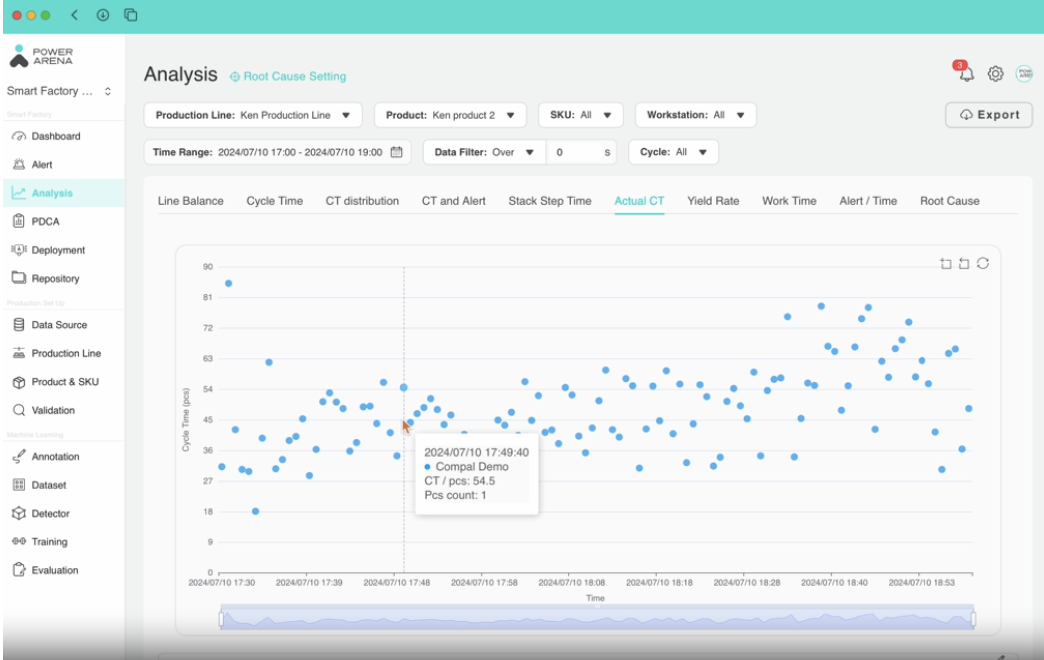

PowerArena’s HOP (Human Operation Platform) displays line analysis and the entire process of operations that triggered alerts.

Manual Production Line Management

Unlike machine operations, which can be precisely tracked through IoT systems, human activities on the production line are much harder to monitor.

Take electronic manufacturing services (EMS) as an example. One operator may need to complete 7 to 8 steps at a single workstation and handle 2 to 3 product changeovers each day. For new workers, the challenge is even greater. Many receive only brief verbal instructions before starting on the line, which increases the chances of errors and defective products.

PowerArena’s HOP (Human Operation Platform) leverages AI vision to generate visualized production line reports, enabling management to gain a comprehensive view of operations.

With AI vision, the system can instantly spot any SOP violations and alert supervisors in real time. Managers can quickly step in, stop the errors, and help the operator correct the process.

AI vision also analyzes these issues and generates reports, giving management valuable insights to improve production line performance and prevent future mistakes.

Still using CCTV to manually review production behavior?

Discover how AI can automate your line management process

Download the Latest Case (2025)

Workplace Safety Enforcement

AI vision can detect humans, machines (robots), and objects in the factory.

Using AI vision, the system checks whether workers are properly wearing protective equipment, such as helmets or safety gloves. If any safety rules are violated, an alert is triggered to remind and protect the employees.

In human-machine collaboration areas, AI vision can also set up a Digital Fence System. When a worker enters a restricted zone, the system immediately issues a warning to prevent accidents caused by unfamiliarity with the movement of robotic arms.

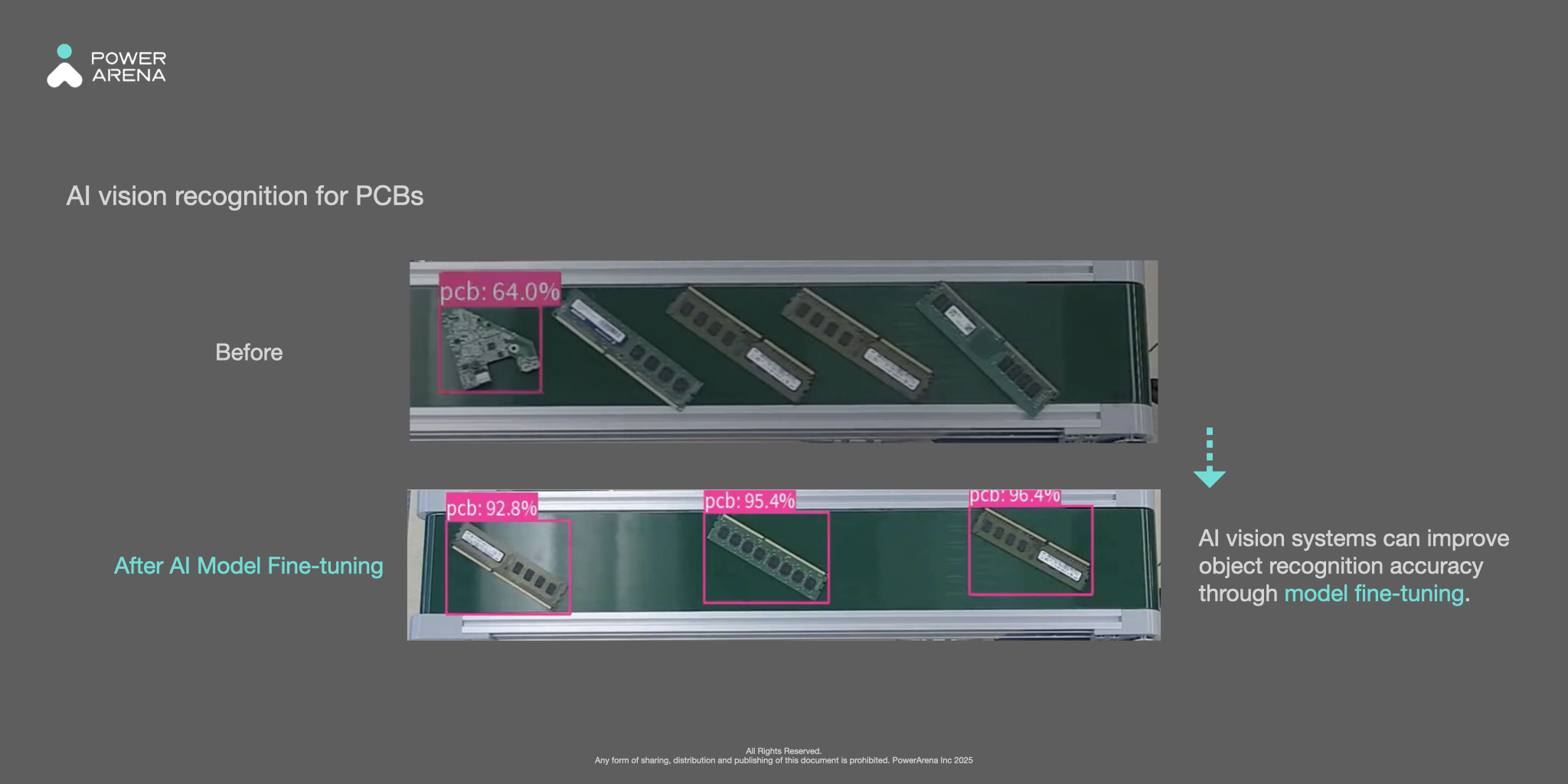

Defect Detection and Quality Inspection

AI vision systems can improve object recognition accuracy through model fine-tuning.

Traditional AOI systems often struggle with lighting, angles, and reflections, leading to high false-positive rates.

At Company A, strict AOI settings caused an overkill rate of 50% —half of the PCB boards were rejected, even though many had no real defects. This led to costly manual reinspection and wasted resources.

AI computer vision offers a smarter approach. AI computer vision learns more product features, adapts to variable conditions, and performs deeper visual analysis. This leads to more accurate defect detection and fewer false alarms, improving overall quality control on the production line.

FAQs

1. What is AI computer vision in a smart factory?

AI computer vision is a core technology in smart factory solutions because it goes beyond machine automation. It enables real-time monitoring of human operations, supports production quality control, and enhances factory safety.

By analyzing video feeds from the production line, AI vision can detect whether operators follow SOPs, identify defects as they occur, and alert supervisors to any safety violations. This creates a more transparent, responsive, and efficient manufacturing environment.

2. Which operations benefit most from AI vision in manufacturing?

AI vision is especially valuable in areas where manual work is involved or where human error can impact quality and safety. Key applications include:

- Manual production lines or workstations with human operations

- Assembly tasks that require strict SOP enforcement

- Visual quality inspection processes

- Human-machine collaboration zones

- Safety-critical work environments

If you’re facing production challenges on your shop floor, please share your situation with our team. We’ll help you explore how AI vision can solve it.

3. What are the main benefits of AI vision for factory managers?

Factory managers using AI vision can:

- Improve SOP compliance and reduce human error

- Detect product defects early and minimize rework

- Monitor production efficiency with real-time data and visual records

PowerArena’s HOP (Human Operation Platform) integrates both machine data and human operation data in real time. This gives managers a complete, unified view of what is happening across the factory floor, enabling faster, more informed decisions.

4. Do I need to rebuild my production line to adopt AI vision?

No.

AI vision can be added to your existing production setup without major changes. You simply need to identify the specific challenges you want to address, such as quality control, safety monitoring, or line balancing.

If your factory already uses MES, IoT, or other systems, PowerArena’s AI vision platform can integrate with them to create a more advanced and unified quality management system.

Table of Contents