By Sursha Wu

What is HOP?

HOP (Human Operation Platform) is PowerArena’s AI vision-powered smart factory solution, designed to unify data, video, and real-time analysis across the entire production floor. It continuously monitors every process, identifies abnormalities, and provides actionable insights for immediate improvement.

HOP empowers operators with clear digital guidance, factory managers with precise production data, and global management with a transparent, centralized control system.

Download Our Latest Customer Success Case

Why you need HOP?

Tracking Production Data is Challenging

Tracking human activities, such as work time and tasks, is far more difficult than monitoring machine data via IoT. Traditionally, engineers rely on stopwatches and manual data entry, which is time-consuming and often incomplete or biased.

PowerArena’s HOP AI vision technology operates 24/7, precisely capturing key production line data such as cycle time, process time, and idle time. It continuously records and analyzes for both data from machine and manual production on the shop floor.

HOP delivers comprehensive, real-time reports to speed up issue detection and enable faster response.

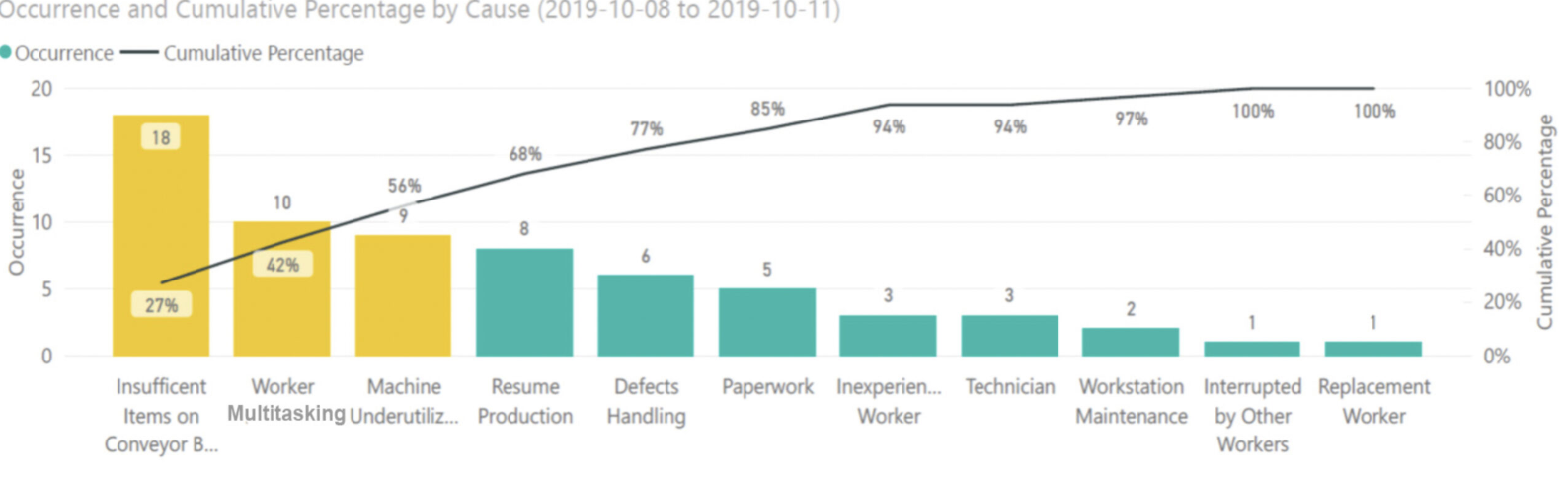

Root Cause Tracing is Time-Consuming and Costly

In manual production lines, tracing process anomalies is often slow and expensive. Without a complete management system, small errors are overlooked, and when quality issues arise, managers struggle to pinpoint the exact time, location, or person responsible. This delay can cause recurring defects and increased costs.

PowerArena HOP automatically tracks manual operations, detects anomalies in real time, and generates instant reports. Each issue is logged with its time, workstation, and cause, while detailed video and data records allow managers to quickly replay and analyze the root cause.

By automating root cause analysis, HOP reduces investigation time and labor costs, while preventing issues from escalating or spreading.

PowerArena’s HOP supports “auto root causes analysis”, uncovering all the reasons that harm the quality and efficiency on the production line.

Managing Human Operations is a Challenge

On labor-intensive production lines, human errors caused by fatigue or inexperience are common. Traditional methods make it difficult for managers to ensure every worker follows SOPs, leading to quality issues.

PowerArena HOP real-time Poka Yoke (error-proofing) to monitor tasks such as component placement or screw-tightening sequences. If a worker deviates from the SOP, the platform instantly detects and alerts the issue, preventing defects from moving to the next workstation.

By automating error detection and enforcing SOP compliance, HOP strengthens process quality control and improves yield rates.

5 HOP Product Features

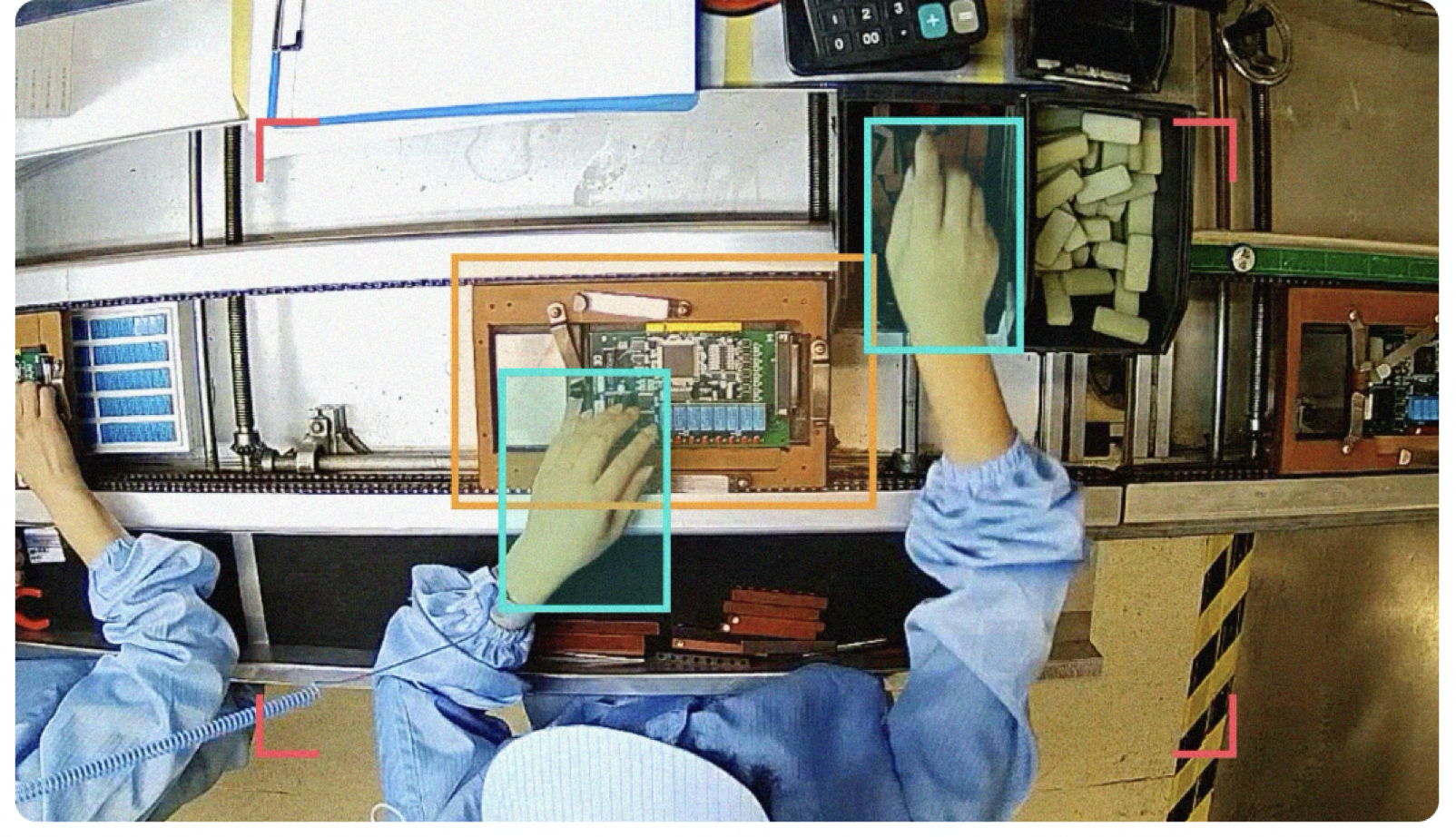

1. AI Poka Yoke for In-Process Error Prevention

Effective in-process quality control (IPQC) prevents defects before they reach the next workstation.

PowerArena’s AI vision acts as an SOP assistant, ensuring operators follow standard procedures throughout the assembly process. When errors are detected, the system instantly stops the workstation, alerts managers, and provides real-time reports to trace and resolve the root cause.

Built on a fundamental AI vision model, HOP can recognize screws, screwdrivers, PCBs, human actions, and other assembly elements. This foundation enables EMS, EV, and semiconductor manufacturers to deploy the platform quickly, reducing setup time and achieving faster adoption compared to other solutions.

PowerArena’s AI computer vision accurately detects humans, objects, and actions. It instantly alerts managers via a platform when operators leave posts too long, abnormal objects appear, or irregular actions occur, ensuring safety and quality.(Video source: POC demonstration line by Compal Electronics)

Curious about how AI vision manages human behavior on the shop floor?

2. Data-Driven Decision for Better Management Efficiency

Data is the foundation of all insights and improvements.

With PowerArena HOP, unstructured video data is transformed into structured analytical reports, while data from machines, IoT sensors, and other equipment is also integrated and analyzed in real time. HOP unified data stream provides objective information to guide production decisions.

Consistent production data enables management to eliminate blind spots, identify the root causes of low quality and inefficiency, and confidently optimize production plans.

PowerArena’s HOP supports real-time shop floor analysis of human operations and machine performance, providing actionable insights to improve quality and efficiency.

3. Continuous Data + Video Collection for Complete Production History

All stages of the production process are automatically recorded and analyzed by PowerArena HOP.

For each product, the platform generates a complete production history, combining clear video records with detailed production data analysis. Managers can easily retrieve this information by product ID for audits, after-sales support, or internal troubleshooting.

This comprehensive history ensures traceability and enhances process transparency.

Want to build a traceable and visual production history for your products?

4. Digital Work Instruction for Better SOP Compliance

Paper or Excel-based instructions slow down real-time support for operators, leading to drops in quality and efficiency.

PowerArena HOP automatically delivers the correct digital work instructions based on each workstation’s SKU. Instructions can include text, images, and videos, with options for auto-play or interactive guidance.

Compared to traditional formats, digital instructions improve update speed and allow operators to instantly review standard procedures, reducing errors like wrong materials or missed steps.

In high-frequency changeover environments, HOP’s digital work instruction also shortens onboarding time, lowers the learning curve, and stabilizes production quality and efficiency.

Interested in this feature?

5. Consistent Performance Facilitating for New Facility

Replicating proven production lines across global sites is challenging, especially when relying on new local talent.

PowerArena HOP, powered by AI vision, records and standardizes the proven SOPs of existing plants. These SOPs can be accessed and applied at any location, enabling consistent quality and management practices across all facilities.

By reducing dependence on manual labor and reinforcing automated oversight, HOP minimizes errors, accelerates production ramp-up, and ensures new sites quickly achieve the same operational efficiency as the original factory.

Results of Implementing HOP

EMS

EMS factory’s performance after HOP implementation

Semiconductor

Semiconductor factory’s performance after HOP implementation

Electric Vehicle

EV factory’s performance after HOP implementation

HOP Solutions

HOP is a unified AI factory management system with multiple product features, structured into three main application levels:

Level 1: Digital Station

Digital Work Instruction

Provides real-time SOP guidance directly on the workstation, helping new workers perform tasks accurately and with confidence. This reduces onboarding time and ensures consistent execution across shifts.

Production Records

Automatically records and tags key process footage, linking each video to the corresponding product ID. Managers can quickly retrieve records for audits, after-sales support, or internal troubleshooting, speeding up response times while significantly reducing storage costs by saving only the most relevant footage.

HOP Digital Station enables production transparency with trackable and traceable data collected via AI Vision & serial number identification. MES integration with open API, HOP consolidates shop floor data via integrated IoT sensors, video cameras to roll back time.

Starting digital transformation? Begin with PowerArena’s HOP to digitize, integrate, and build your smart factory.

Level 2: AI Line Balancing

AI vision automatically collects and analyzes production data 24/7, capturing cycle time, process time, and idle time with precision. Every movement or incident on the line is recorded. Based on the reports, engineers can quickly identify and fix the issues.

HOP AI Line Balancing captures and records every detail of conveyor, workstation and operator activity around the clock. The result is high quantities of high-quality data giving in-depth views of assembly line activities.

Struggling with production quality and efficiency bottlenecks?

Level 3: AI Poka Yoke

Poka Yoke = error prevention

AI vision detects abnormal operations in real time and immediately alerts supervisors. Managers can view the cause and video footage directly from the platform, allowing them to stop the issue before it spreads.

When integrated with MES or IoT systems, AI vision fills in the gaps that traditional data cannot capture, ensuring that no undetected errors reach the market. This prevents defects at the source and supports zero early-stage warranty claims.

HOP AI Poka Yoke oversees the crucial workstations in your assembly line with AI vision. Identifies any error in a work step or deviation from SOP.

Curious about how AI vision manages human behavior on the shop floor?

Table of Contents