What…is a Time and Motion Study?

A time and motion study is a cornerstone methodology for enhancing productivity by analyzing and optimizing workflows. Rooted in industrial engineering, it combines time study, which measures task durations, and motion study, which focuses on the physical movements involved in processes. This dual approach identifies inefficiencies and supports continuous improvement, paving the way for time efficiency in diverse industries.

Time Study: A method to measure how long tasks take, helping to set standards and improve efficiency. It typically involves observing and timing tasks, often using stopwatches or software tools.

Motion Study: A method to analyze the physical movements involved in a task to identify and eliminate inefficient actions. Its goal is to streamline workflows, reduce worker fatigue, and optimize processes for improved productivity.

Download the Case Study: EMS factory boost 5.2% UPH with AI

When…did Time and Motion Studies originate?

Time and motion studies originated in the late 19th and early 20th centuries, pioneered by Frederick Winslow Taylor and Frank and Lillian Gilbreth. Taylor’s time study analyzed tasks to identify efficient methods, while the Gilbreths’ motion study focused on eliminating unnecessary movements, using their “Therbligs” system to streamline workflows.

These methods revolutionized industrial productivity and influenced modern practices like lean manufacturing and Six Sigma, optimizing workflows across industries. Their impact is also highlighted in Cheaper by the Dozen, showcasing the Gilbreths’ innovations.

Why…are they useful?

Time and motion studies improve productivity and efficiency by analyzing workflows to identify and eliminate inefficiencies. They offer measurable insights into cycle time, takt time, and value-added activities, supporting better resource allocation, workload balancing, and process standardization.

Preparing for a Time and Motion Study

Successful time and motion studies begin with thorough and strategic preparation. Here’s how to set the stage for impactful results:

- Define Clear Objectives: What do you want to achieve? Reducing lead times, boosting productivity, or improving ergonomics—clear goals will guide your efforts.

- Prioritize the Right Processes: Zero in on tasks or workflows with obvious inefficiencies; the bigger the bottleneck, the greater the opportunity for improvement.

- Collaborate and Engage: Keep employees in the loop to build trust and ensure smooth cooperation. Transparency is your secret weapon.

Quick Summary: Preparation is all about setting clear goals, tackling the most inefficient workflows, and fostering collaboration.

Conducting the Study and Data Analysis

- Collect Data: Capture every detail by recording task times and observing worker movements. Precision here sets the foundation for impactful insights.

- Uncover Hidden Variations: Consider the nuances—shift timings, worker experience, and even seasonal fluctuations can dramatically influence performance.

- Turn Data into Actionable Insights: Utilize powerful analytics platforms to interpret metrics like cycle time, takt time, and value-added time. This analysis reveals inefficiencies and highlights opportunities to optimize.

Key Metrics Defined:

Cycle Time: Total time to complete one unit of production.

Takt Time: Rhythm your production must follow to meet customer demand.

Work Time/ Value-Added Time: Time spent on activities that directly contribute to the product.

Implementing Improvements

Post-analysis, implement targeted improvements:

- Eliminate Waste: Streamline workflows and remove non-value-adding steps.

- Enhance Ergonomics: Redesign workstations to minimize strain and optimize movement.

- Provide Training: Equip workers with the knowledge to adopt improved workflows effectively.

Challenges in the Traditional Method

Despite their utility, traditional time and motion studies conducted manually face several limitations:

Observer Bias:

Manual observations are prone to human error and inconsistencies.

Hawthorne Effect:

Workers often modify their behavior when they know they are being observed, leading to inaccurate data.

Limited Scope:

Traditional methods often fail to capture data across multiple shifts, locations, or seasons, missing critical variations.

Resource Intensity:

Conducting these studies manually requires significant time and effort, making it impractical for continuous monitoring.

Insufficient Evidence:

The lack of robust data can undermine the improvement plans proposed by industrial engineers, making it challenging for them to present strong evidence when questioned by managers.

How…we do it with AI

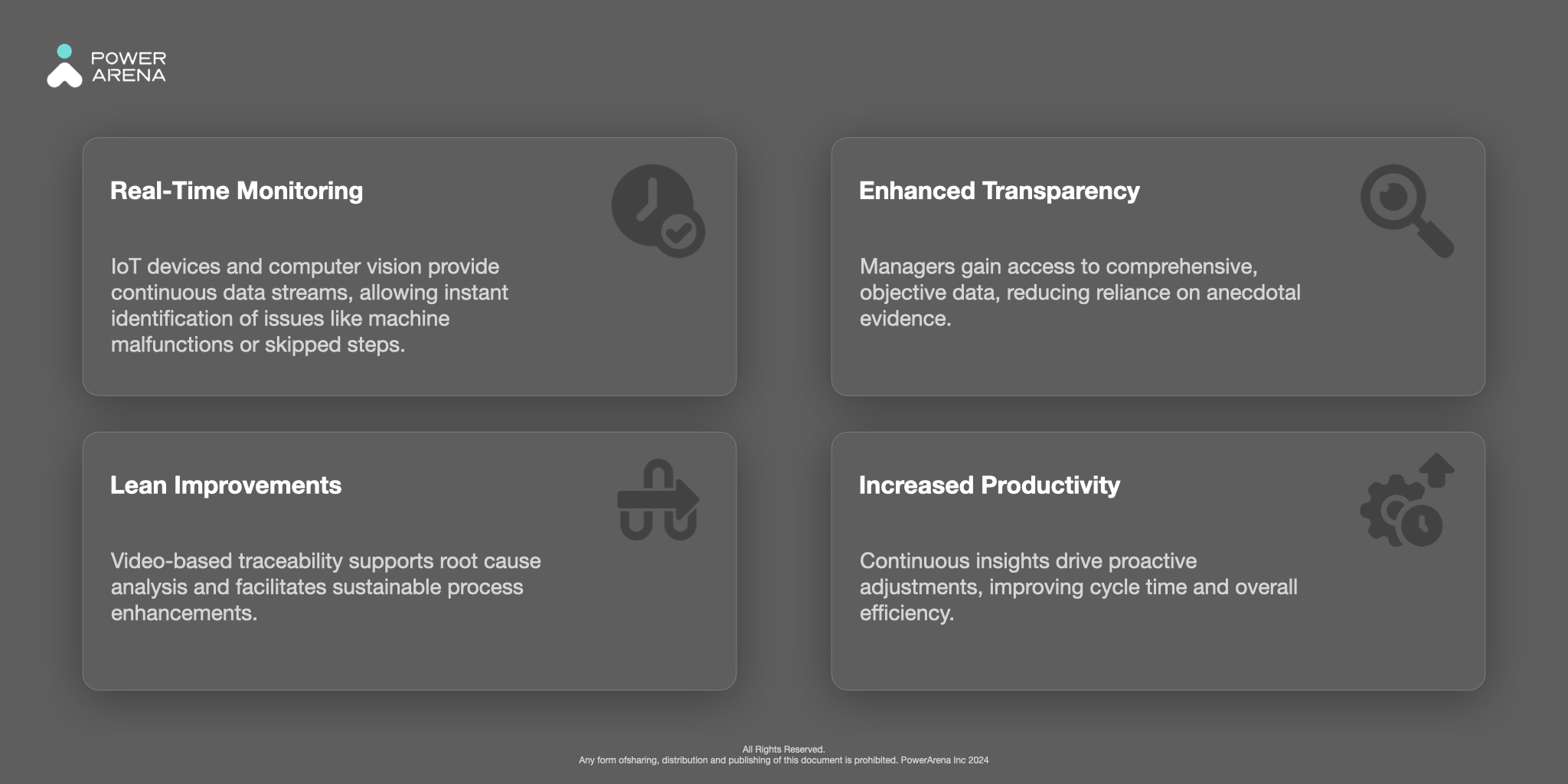

Integrating time and motion studies with smart technologies elevates their impact, addressing traditional limitations such as the Hawthorne Effect and process variations. Key advantages include:

How can we help you?

Case Study: AI Vision Smart Monitoring of Cycle Time

At a remote Vietnamese factory producing hybrid inverters for solar panels, limited industrial engineering (IE) resources and nonstop production caused a two-day delay in data collection, hindering real-time workflow optimization.

By adopting AI vision via the Human Operation Platform (HOP), the factory gained real-time insights and transformed its operations. Here’s how the system works:

- Cycle Time Collection: IE no longer needs to conduct studies manually; AI vision tracks cycle times accurately and continuously across all 15 workstations.

- Real-Time Data Generation: Managers can access a complete production dashboard at any time, gaining instant visibility into the production status and bottlenecks.

- Root Cause Analysis: Engineers analyze downtime and inefficiencies using Pareto charts generated by AI, enabling quick identification of issues like unbalanced lines, material shortages, and motion delays.

- Improvement Validation: Real-time insights allow engineers to test and validate solutions instantly, streamlining the improvement process.

The Results:

5.2% Increase in UPH:

Output rose from 211 to 222 units per hour.

Rapid Improvement Validation:

Engineers tested and confirmed solutions in real time.

4X ROI:

The investment in AI vision delivered exceptional returns.

AI vision smart monitoring ensures transparency, real-time issue resolution, and actionable data for sustained improvements. Discover how similar solutions could revolutionize your production line.

Conclusion

Modern time and motion studies integrate traditional methodologies with cutting-edge technologies like IoT and AI vision, delivering unparalleled insights and efficiencies. As industries face challenges such as labor shortages and shifting customer demands, these studies remain vital in driving operational excellence. Businesses adopting these advancements can achieve sustained productivity, cost savings, and enhanced employee satisfaction—positioning themselves for long-term success in the era of smart manufacturing.

Table of Contents