By Sursha Wu

Production management is essential to modern manufacturing. It ensures that factory operations are well-planned, quality-controlled, and resource-efficient.

As factories move toward digital transformation, AI-powered tools like PowerArena’s HOP (Human Operation Platform) are making production management smarter, offering real-time visibility, actionable insights, and consistent control across lines and sites. In this blog, we explore what production management is, why it’s critical, and how AI vision technology helps factories operate with greater speed, accuracy, and scalability.

This blog is for:

-

Factory managers who need real-time visibility into shop floor operations

-

Quality and operations leaders focused on reducing errors and enforcing SOP compliance

-

Manufacturing decision-makers driving AI transformation and smart factory initiatives

What is Production Management?

Production management refers to the planning, execution, and control of manufacturing processes to ensure products are produced on time, meet quality standards, and achieve optimal efficiency. It covers essential tasks such as scheduling, monitoring production data (like cycle times, takt time, and so on), ensuring SOPs compliance, and managing continuous improvement.

In the age of smart factories, production management is no longer manual or isolated.

With AI solution such as PowerArena’s HOP (Human Operation Platform), manufacturers gain real-time visibility, data-driven decision support, and scalable operational control.

How AI Enhances Production Management

Why is Production Management Important?

Effective production management keeps factories running efficiently and minimizes errors. Here’s why it matters:

- Cuts Costs – Increases output while reducing waste to boost margins.

- Improves Competitiveness – Ensures timely delivery and consistent product quality to stay ahead.

- Achieves Business Goals – Supports growth with reliable production and satisfied customers.

- Strengthens Brand Trust – Builds long-term customer confidence through dependable performance.

- Optimizes Resources – Reduces waste and promotes both sustainability and worker well-being.

Traditional vs. AI Vision Management

Traditionally, managers and engineers rely on manual records to analyze performance, spot inefficiencies, and identify quality issues. However, this method has clear limitations. People can’t observe every process or catch every problem, leading to missed issues and ineffective decisions.

Modern AI vision production management platform addresses these gaps by providing real-time data and video insights. It gives managers the full picture, allowing them to make faster, smarter decisions based on complete, accurate information.

The production manager is using HOP(Human Operation Platform)to see the AI vision analysis of the production line.

How does AI vision work in production management?

Production and Operations Management

Production management focuses on execution, such as monitoring cycle times, work quality, and operator behavior. Operations management covers broader areas, including resource planning, procurement, and logistics.

Digital platforms like PowerArena’s HOP (Human Operation Platform) connect the two by providing a shared and real-time view of production data. Both floor managers and regional leaders can access the same performance metrics and visual records, keeping daily operations aligned with overall business strategy.

Benefits of AI Vision Production Management in Manufacturing

1. Building a Reliable Production History

AI vision systems continuously record each stage of production using video and data, creating a complete digital history for every product.

This enables full traceability and process transparency, helping teams quickly verify what happened, when, and where.

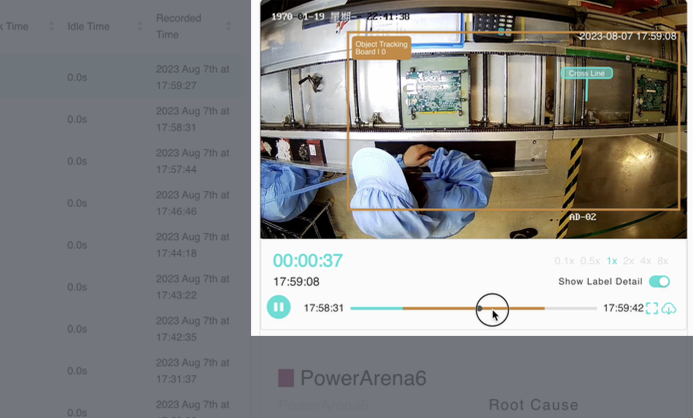

With 24/7 recording of the production, HOP allows engineers to track and trace abnormal events with clear and real-time production video.

2. Turning Data into Actionable Insights

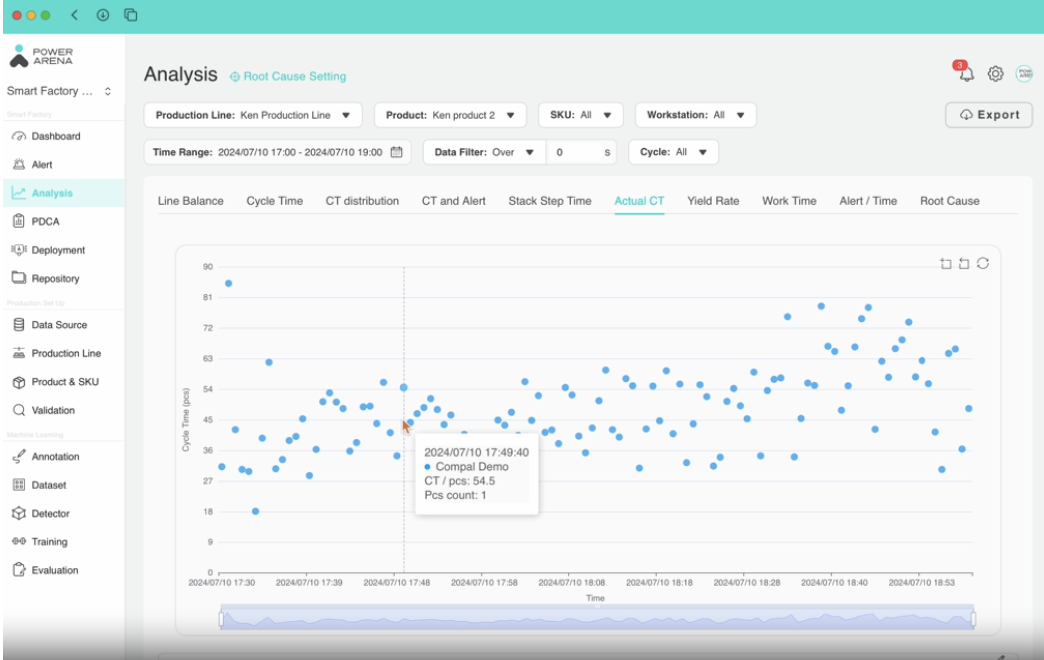

AI vision transforms raw visual and operational data into structured analytics, turning cameras into intelligent management.

Managers no longer rely on assumptions or incomplete reports. Instead, they get objective analyses and insights into cycle times, operator behavior, and workflow gaps. With this real-time clarity, teams can identify inefficiencies and optimize production plans with confidence.

HOP (Human Operation Platform) is supported by AI vision, automatically calculating and analyzing manual line data.

3. Trace Issues to Their Source

When a defect or delay occurs, AI lets managers rewind the process to pinpoint the exact step, time, and operator involved.

This speeds up root cause identification, prevents recurrence, and reduces the time wasted guessing or checking across departments. By understanding the “when” and “why” behind a problem, manufacturers can act fast and fix it for good.

4. Prevent Mistakes Before They Happen with AI Error Prevention

Think of AI vision as a digital supervisor watching each step of the process. It checks if workers are following standard operating procedures (SOPs) and immediately alerts the team if something goes wrong.

When an error is detected, such as a misplaced part, missed step, or excessive cycle time, the system instantly alerts the workstation, enabling managers to intervene before the issue escalates.

This proactive IPQC system minimizes rework, reduces dependence on quality assurance teams, and ensures consistent quality throughout each shift.

Situations such as leaving the workstation or exceeding standard operation time are automatically detected by AI vision and reported to the line supervisor. Video footage: Compal’s POC demonstration line.

5. Replicate Quality Across Sites

Opening a new factory often leads to inconsistent quality and slower ramp-up times.

AI vision helps solve this by allowing new sites to mirror the best practices of existing lines. With scalable models and SOP-based management, manufacturers can replicate success without retraining from scratch, ensuring consistent output and faster deployment across regions.

Want to enable global visibility and fast deployment across sites?

Production Management Software Solutions

PowerArena HOP (Human Operation Platform)

HOP is PowerArena’s AI vision solution designed for labor-intensive production lines. It continuously records and analyzes workstation video, providing real-time insights into operator actions and line performance. By combining visual footage with production data analysis, HOP gives managers a complete view of what’s happening on the floor—anytime, anywhere.

FAQs

1. What is production management and why is it important?

Production management is the process of planning, executing, and controlling manufacturing operations to ensure efficiency, quality, and on-time delivery. It helps reduce costs, minimize waste, and improve product consistency—key factors in staying competitive.

2. How is AI used in production management?

AI vision enhances production management by analyzing real-time data and video from the shop floor. It can detect deviations from SOPs, monitor cycle times, identify bottlenecks, and provide insights for faster decision-making, leading to higher productivity and fewer errors.

More details about how AI vision helps production management:

3. Can AI help with quality control in manual production lines?

Yes. AI vision systems can track every step of manual operations, ensuring SOP compliance and detecting anomalies instantly. This reduces rework, prevents defects, and provides a traceable production history for audits and customer assurance.

4. What should I prepare for AI vision adoption in my production management?

You only need to share your current production challenges and the scenarios or areas where you’d like to apply AI.

PowerArena’s HOP platform supports everything from manual operation monitoring to process optimization. We’re here to explore your needs and help you find the most suitable deployment approach

Table of Contents