By Dave Chue

Intro

5 days, 3 years and 205,000 total attendees, 2023’s China International Industrial Fair had once again gave us a glimpse to the very future of what tied the world together—Manufacturing.

With global, local and first-time exhibitors all rushed to CIIF showcasing their latest and greatest technological advances in their respected field, many had attracted over thousands of visitors to their booth. Aligning the current effort of building high-quality industrial wide digital transformation with manufacturing process powered by 5G, AI and IoT. Cutting-edge products and innovations, from robots, 5G, ESG to automation, are as shining as always, amongst the regulars every year that are seeing incremental improvements for the past 3 turmoiled years. Applications in AI are popping out from the scene like a shooting star, rocketing to the sky.

Although, we did made some interesting discovery.

Robotics are as big as always

“Robotics is experiencing significant growth due to global megatrends, including a shrinking workforce, supply chain disruptions and a fundamental need to operate more sustainably and efficiently,” said Marc Segura, president of ABB Robotics Division.

We believe the eventual future of robotics taking over the manufacturing scene, though we’re also seeing the gap between that vision and real life application had never been wider.

“Imagine a fully automated product line where it will take 1M RMB to setup, and with the production volume, it will need another two years to even the ROI. But with today’s tech trend, most consumer products aren’t having such long life cycle. You then end up loosing money year over year using robotics and full automation.” Said production manager of global top 3 EMS provider.

The need of human beings in production line remains a stronghold to the complete automation. Though we don’t want to admit it, the market is definitely reacting to it. The foot traffic, according to exhibition, are two to three folds in IAS hall where the latest solution of industrial smart implementation of tech and labour infused operations are located.

The next big thing. Vision.

Vision in two fields are definitely popping up from the entire scene. AR & Computer vision.

What we imagine Augmented Reality might still takes a few years to be applicable into real life factory applications, we’re seeing a decent amount of sizable leap in using AR glasses to push safety check in certain high regulated industries.

Also seeing a higher amount of vision solution provider embracing and deepening their offering with tied in computer vision, given it’s 2D or 3D.

These are heavily used in the space of AOI. For the tiniest fault detection, that can even learn where if the glue is applied correctly on a reflective metal surface. To where factory workers can implement AR glasses into security check of the production plant, just by walking through it and look at each critical spots.

Reflect & realign operational fundamentals. From digital transformation to digital twins.

First steps into digital transformation, are to digitize your operation.

To speed it up and ease the pain of transformations, big players like Siemens & Schneider are pushing out an ecosystem-wide solution offering. With fundamentals offering such as digitizing the operations to further applications like digital twins.

Digital twins can be grouped into three section: Designing production. Production process & output. And Operation.

In these three sections. Manufacturers are inclined to use all sorts of tools gathering information from the production line in order to maintain their operational integrity and flexibility. By visualizing the truth of what was unseeable to projecting the trajectory of what can be done if they do move their production else where in the world. Especially in this age that manufacturers are all looking for the next best stage to be, given it’s SEA or India.

We’re seeing manufacturers are now taking a different stand where they’re taking the innovations back into their own production space and start from the fundamentals.

AI. Yes, of course. AI.

First thing first, AI isn’t here to replace human, it never was, it’s here to compensate what we can’t achieve. AI plays in the space where our normal human being couldn’t, to remain unbiased, untired, and omni presence.

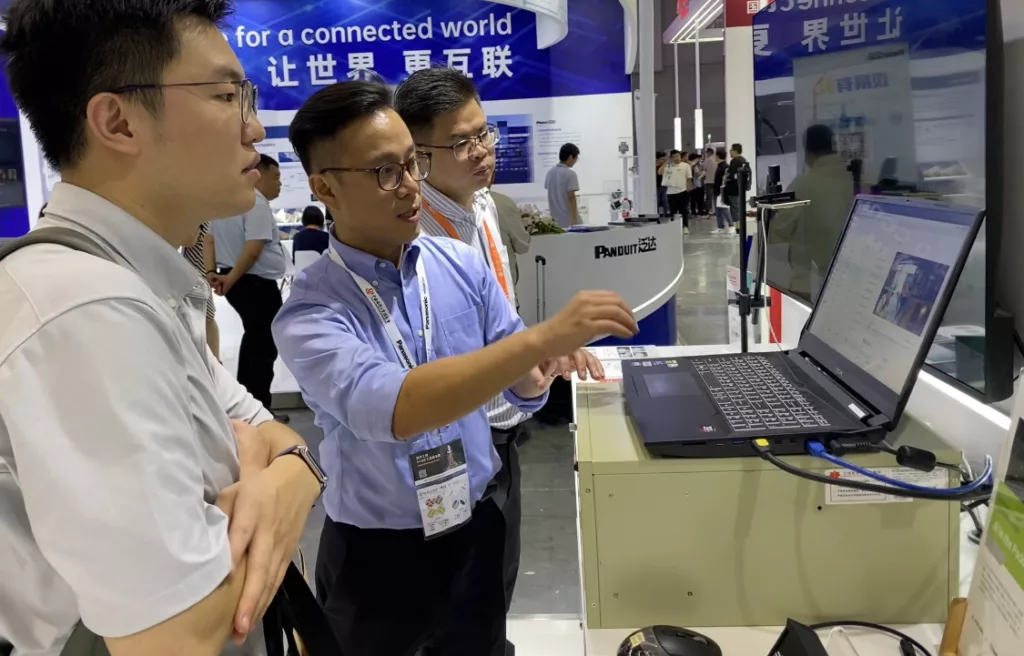

Human Operation Platform, an AI solution to assist transforming manufacturers with labour intensive production line. An digitized production powered by artificial intelligence is the answer to top manufacturers when they’re minimizing the cost while supercharging their production to the max.

A perfect solution that implemented the most obvious sense of all—Vision. To completely digitizing your production line, extracting labour information and visualize your production like never before.

A just a simple camera*, AI are able to record & safeguard each work steps of your operators. Granting manufacturers with sufficient data set to raise overall productivity and real-time alert to safeguard product quality output leaving all the defects within the factory and never into the market.

(*Camera system must be integrated into data server or edge server with minimum tech specs requirements of processing AI’s algorithm, in order to record and analyze production line data in real-time.)