What is a Lighthouse Factory?

Core Values of Lighthouse Factories

Lighthouse Factories stand out by excelling in the following four areas:

1. Scaling Advanced Industry 4.0 Technologies

Lighthouse Factories don’t just adopt AI, IoT, and other technologies.

Their key objective is to scale these point solutions and integrate them into a unified smart manufacturing system, enabling end-to-end digital transformation.

What are the benefits of integrating AI vision, IoT, and MES into a unified platform?

This level of integration empowers factories to stay agile, especially in today’s High-Mix Low-Volume (HMLV) market, while gaining stronger control over quality, efficiency, and overall production performance.

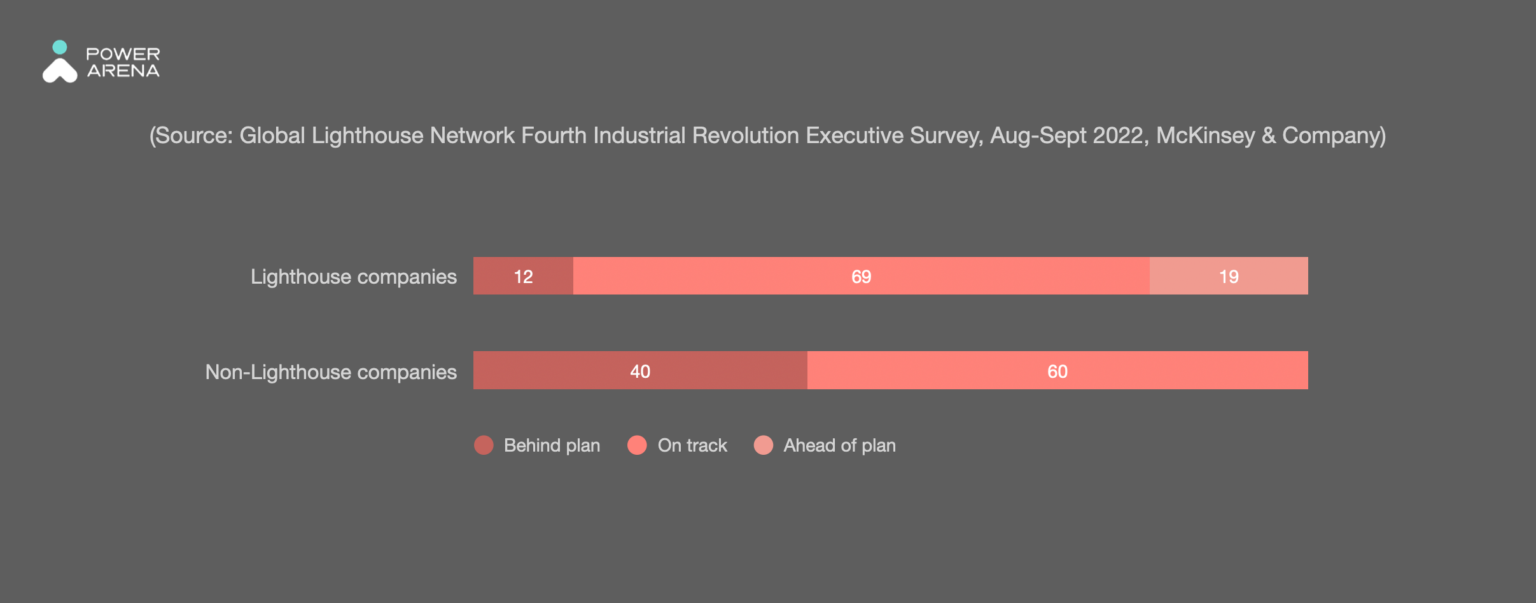

88% of Lighthouse Factories are on track or ahead in scaling Industry 4.0 technologies, compared to just 60% of non-Lighthouse companies.

2. Focusing on Operational Efficiency and Lean Manufacturing

Lighthouse Factories achieve high efficiency through continuous improvement and the disciplined application of lean manufacturing. They reduce waste, optimize resource use, and improve line performance across operations.

The first step toward these goals is building full production visibility and creating a data-driven environment. This allows factories to make faster decisions, respond to production changes or market demands, and ultimately lower costs while increasing productivity.

3. Applying ESG-Driven Practices

Lighthouse Factories lead in environmental responsibility by embedding sustainability into their operations. They reduce energy use, carbon emissions, water consumption, and material waste while maintaining high performance.

As part of their Industry 4.0 journey, these factories adopt green technologies and processes to achieve eco-efficiency, showing that sustainability and operational excellence can go hand in hand.

See how a Global Top 5 EMS cut the waste and increased UPH by 5.2%.

Overview of Current Lighthouse Factories

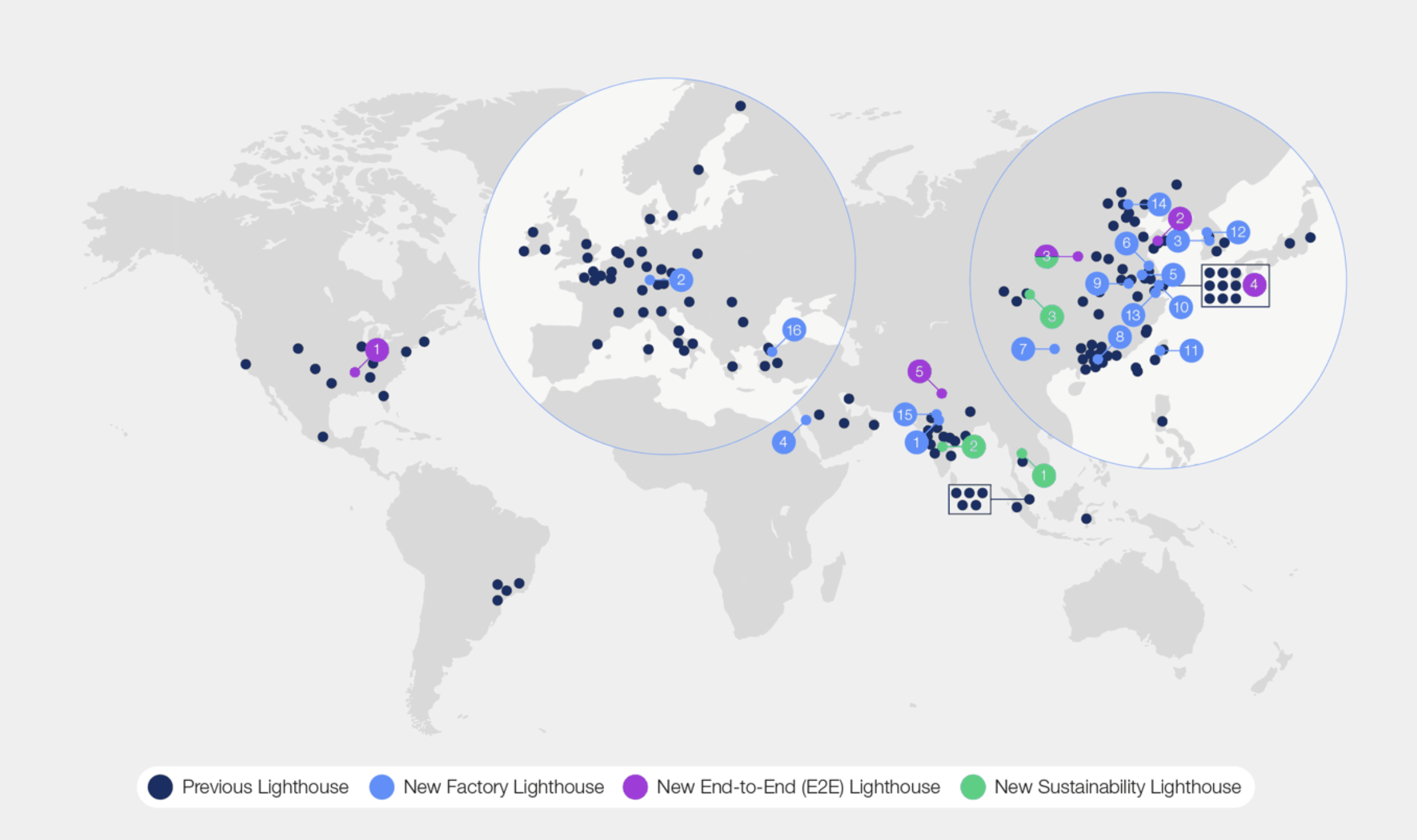

As of today, 153 factories across various industries have been recognized as Global Lighthouse Factories. These leaders set the benchmark for smart manufacturing by applying and scaling advanced technologies to achieve operational excellence.

Haier Qingdao: End-to-End IoT Optimization

Haier’s IoT-enabled washing machine plant in Qingdao has implemented 136 smart applications, including 5.5G, Digital Twin, and intelligent material scheduling. This system tracks material carts in real time, optimizing delivery routes and improving factory performance:

- 50% boost in efficiency

- 80% reduction in material shortage downtime

- 33% increase in labor productivity

- 32% reduction in product costs

Key Tech in Lighthouse Factory

AI Vision and Machine Learning

AI computer vision helps factories optimize operations by analyzing the entire production process in real time, supporting quality control and continuous improvement.

AI vision also detects product defects and human operation errors on the line, ensuring SOP compliance and identifying missed steps, incorrect sequences, or delays. This enables managers to reduce waste, enhance quality, and improve overall efficiency.

AI vision captures operators’ behavior in the shop floor. If there is any SOP violence, it will sent alerts to the management immediately.

IoT and Smart Sensors

IoT devices and smart sensors form the digital backbone of Lighthouse Factories. They connect machines, processes, and operators across the production line, enabling real-time monitoring of equipment status, product quality, and human operations.

Beyond data collection, IoT sensors can also be integrated with cameras to capture and store key videos during critical operations, enhancing traceability and building a complete visual production history.

Want full production traceability?

Robotics and Automation

Automation technologies like robots, CNC machines, and automated storage systems handle repetitive, high-precision tasks, allowing human workers to focus on more flexible, value-added work. Collaborative robots support heavy or hazardous tasks, improving both productivity and workplace safety.

Data Analytics and Digital Twin

Data analytics, combined with Digital Twin technology, gives factories a powerful simulation layer. Digital Twins create a virtual replica of the production environment, allowing managers to test changes, optimize processes, and troubleshoot issues without interrupting real-world operations.

This integration supports faster decision-making and continuous improvement based on real-time insights and predictive modeling.

Lighthouse Factory Case Studies

EMS Manufacturing Factories

How to become a Lighthouse Factory?

To become a Lighthouse Factory, manufacturers must move beyond using isolated tools and build a unified smart manufacturing system. By integrating IoT, AI vision, machine learning, MES, and data analytics, they gain real-time visibility, predictive insights, and operational control. Success depends on scaling these technologies across production lines while aligning with lean practices, sustainability goals, and workforce development. Factories that lead this transformation achieve greater agility, improved quality, and higher efficiency. These are the core characteristics of a Lighthouse Factory in today’s rapidly evolving manufacturing landscape.

Ready to take the first step?

Learn how unified platforms can accelerate your Lighthouse journey.

Table of Contents