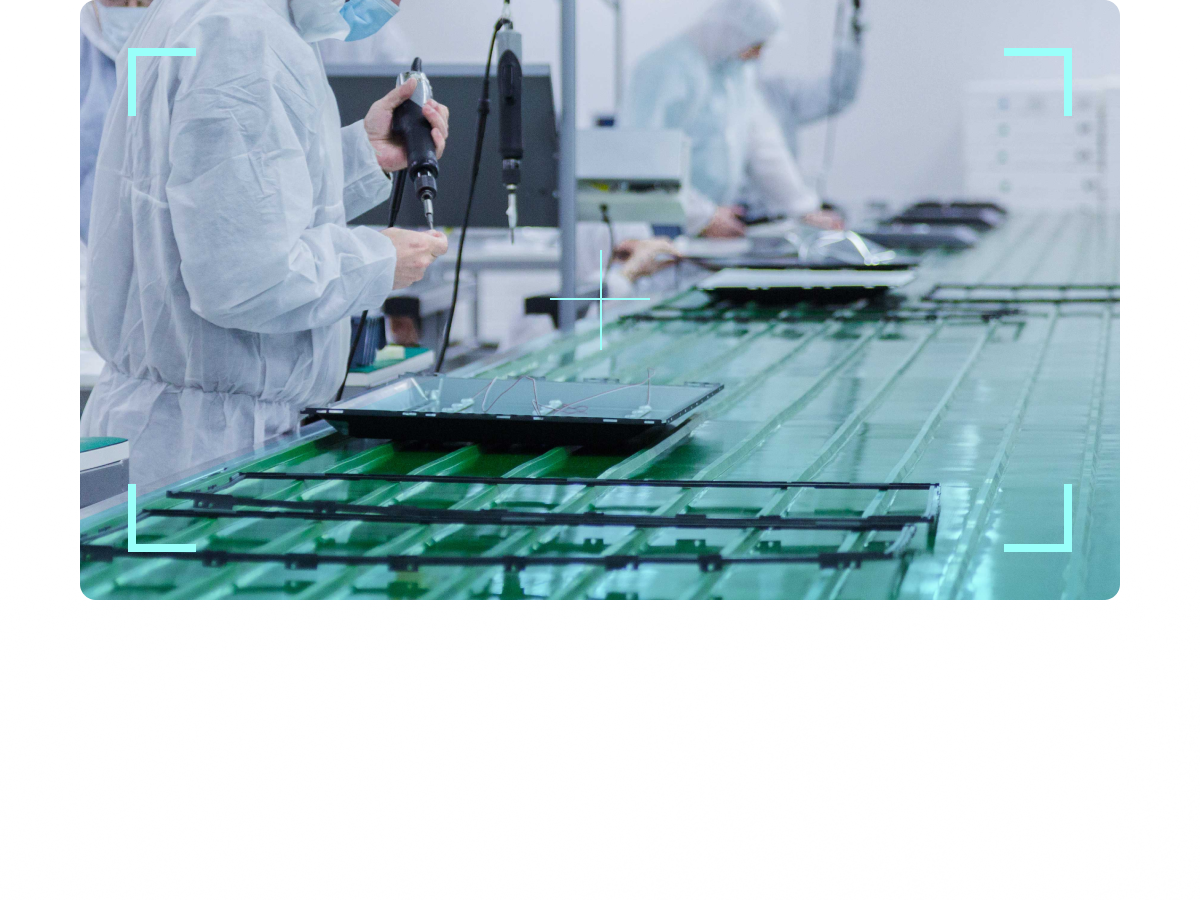

Trace errors and increase workplace efficiency with HOP Digital Station.

Farewell, workstations of yesterday.

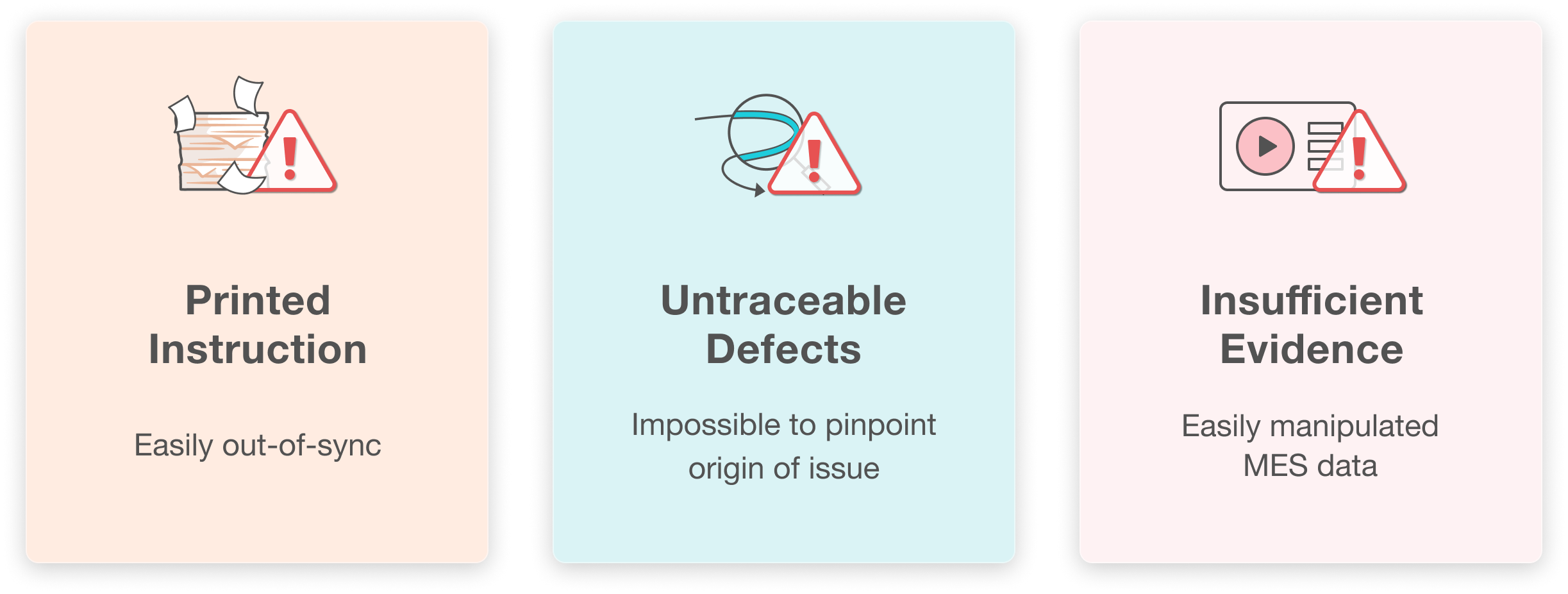

Line operators are trained according to printed manuals. At their station they follow printed instructions. Defects can typically only be traced to a batch or line. It’s often impossible to identify exactly what went wrong. Even it’s found a MES exported CSV file is insufficient to reflect the reality of production.

Introducing

Digital Station

Track & Trace. Production Transparency. Full MES Integration.

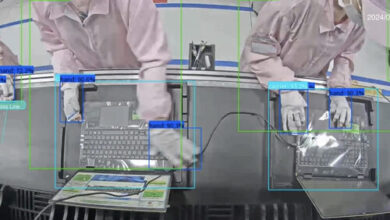

HOP Digital Station enables production transparency with trackable and traceable data collected via AI Vision & serial number identification. MES integration with open API, HOP consolidates shop floor data via integrated IoT sensors, video cameras to roll back time.

Full Production Track & Trace.

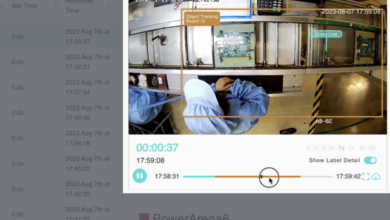

HOP Digital Station enables factory to fully track and trace their production detail with video recording and serial numbers assigned to each products passing through at each stations via scanners or RFID. This footage can then be searched via the serial number to reveal full production history.

MES Integration & API Supported.

HOP Digital Station consolidate shop floor data via integrated IoT sensors, video cameras and MES to roll back in time. With full support of public API and full integration with MES. Factories can now integrate existing system and devices with ease.

Stay Up-to-Date with Digital Instructions

HOP Digital Station syncs up your standardized procedure and production documentation to ensure every station following the latest guideline. Eliminating outdated information and the hassles of updating production documentation manually. Making onboarding and training process faster and easier.

HOP Digital Station

Case Studies

PowerArena HOP has already delivered impressive ROI in a factory similar to yours.

These case studies cover only a fraction of PowerArena HOP installations. Tell us about your situation and we’ll share relevant data and details.

Main Applications

Digital

Station

Digital Station

- Reduce downtime

- Monitor the interaction between workers and machines

- Detect long delay and assist root cause analysis

- Improve machines overall equipment effectiveness (OEE)

AI Line

Balancing

AI Line Balancing

- Streamline workflow productivity

- Identify opaque and complex bottlenecks

- Workflow metrics that visualize the factory floor

- Empower the workforce by strengthening teamwork and gaining productivity

AI

Poka Yoke

AI Poka Yoke

- Maintain standard operating procedure compliance

- Detect and alert workers who skipped work steps

- Ensure quality through SOP compliance

- Customizable SOP detection software