By Sursha Wu

What is AI Vision?

AI vision recognition analyzes, processes, and interprets images using artificial intelligence. The goal is to enable computers to “see” and “understand” images as humans do, recognizing objects, people, and scenes. It relies on Convolutional Neural Networks (CNNs), a deep learning technique designed for image analysis and pattern recognition.

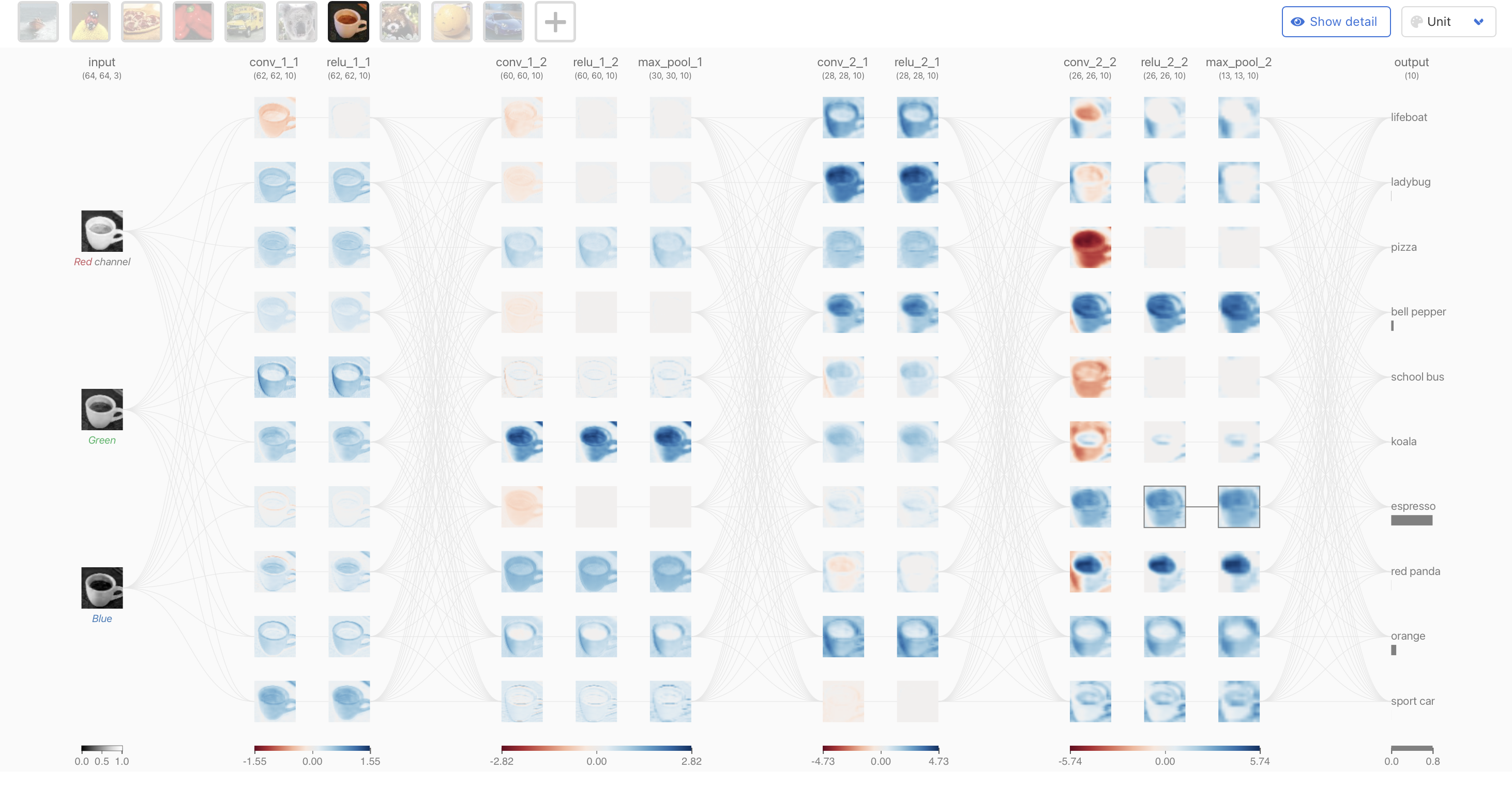

CNNs extract essential features from images through convolution layers. Each layer processes specific areas, performing mathematical operations to enhance key characteristics. These refined features are then used to classify images accurately.

In machine learning, a classifier categorizes data points into different groups. For example, an image classifier identifies objects in images and labels them (e.g., bird or airplane). Convolutional Neural Networks (CNNs) are specialized classifiers designed for such tasks.

Reference: CNN Explainer

Each “layer” of computing units analyzes and processes complex data. Neuron in each layer extracts features from the previous layer and pass them forward for further refinement. Source: CNN Explainer

Common Applications

1. Autonomous Vehicles

AI vision helps self-driving cars detect objects such as pedestrians, vehicles, and traffic signs. It enables real-time environmental analysis for navigation and collision avoidance, ensuring safe driving.

2. Medical Imaging Diagnosis

AI vision analyzes medical images like X-rays, CT scans, and MRIs. It assists doctors in detecting diseases with greater accuracy, improving diagnostic efficiency.

3. Manufacturing Industry

- Safety

AI vision enhances workplace safety by detecting hazardous behaviors and potential risks. It identifies workers not wearing safety helmets or entering restricted machine zones, preventing accidents and ensuring compliance. - Smart Factory Management

AI vision automates image collection and analysis, allowing factory managers to monitor production 24/7.

For example, Compal Electronics integrated PowerArena AI vision to analyze workstation cycle times and workflows. AI vision converts collected images into digital, visualized production reports, providing managers with real-time production insights. It also enables playback of recorded footage to investigate production anomalies.

Download the Case study: How Compal Electronics uses AI vision and LLM for production line management.

Compal Electronics adopted PowerArena AI vision in its production line.

Applications of AI Vision Recognition Technology

Focusing on “Men” and “Method” in Manufacturing: Advanced Applications of AI Vision

In manufacturing, the 4M1E framework—Men, Machine, Material, Method, and Environment—highlights the five core elements of in-process management. AI vision can effectively reduce errors specifically related to “Men” and “Method.”

Men

Read the Full Case Study: Why Do Factories Need AI Vision for Factory Management?

Over 72% of factory tasks are still completed by human. Robots have yet to replace all the work in the factories.

Source: Kearney

On labor-intensive production lines, AI vision creates an efficient management system with its “image-based” features. Human behavior is unpredictable due to reasons like attention, physical condition, or experience. All these factors impact product line efficiency and product quality. Traditionally, engineers spend many time and efforts to collect and analyze the data from the production line to reduce these potential errors.

With AI vision, key producing behavior on the line can be traced continuously. It reduces the workload on management and provides a complete production record to support decision-making.

Method

A time study for one product requires approximately 24–48 hours of an industrial engineer’s time, yielding only about 15 minutes of data per month.

To optimize production efficiency, industrial engineers need a complete view of the line, where data plays a crucial role in quickly identifying the root of production issues.

However, most production data collection still relies on manual recording. Engineers use stopwatches to time tasks and record observations on paper. This method is inefficient and prone to bias.

AI vision enables continuous data collection and instant root-cause analysis. It helps engineers quickly identify bottlenecks, eliminate management blind spots, and accelerate process optimization. Book a Demo & Consultation: Learn more about advanced AI vision applications.

Success Cases in Smart Factories

Case 1: Digital Workstation (Server Manufacturing)

Challenge: Workers often scratch the metal surface of servers when using tools like screwdrivers, affecting product appearance. Without a good tracking system, management can’t easily identify when or where issues occur. This makes problem-solving harder and risks delays.

Solution with AI vision: AI vision continuously records the production process. It allows managers to trace issues like scratches or dents quickly, cutting down the time needed for root cause analysis.

Case 2: Line Balancing (Electronics Component Manufacturing)

Challenge: A time study for production lines requires significant time and effort and often results in incomplete data, with “non-value-added tasks” frequently omitted.

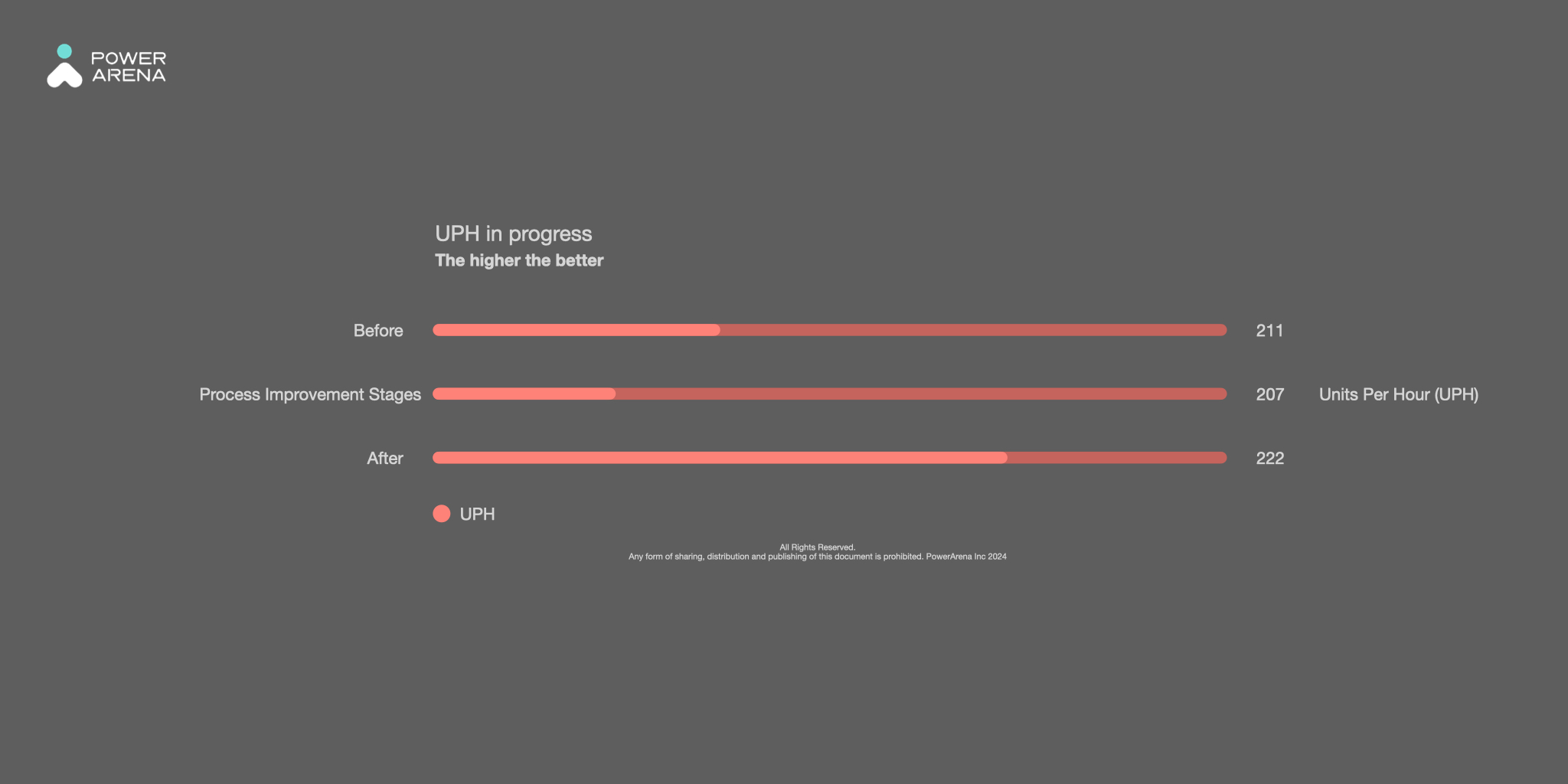

After adopting HOP, the production line achieved a 5.2% increase in UPH (Units Per Hour).

For instance, the plant noticed low production efficiency at specific times and operators leaving stations early but lacked long-term data to fully evaluate line efficiency and resource allocation.

Solution with AI vision: AI vision automatically collects and analyzes production data 24/7, capturing cycle time, process time, and idle time with precision. Every movement or incident on the line is recorded. Based on the reports, engineers can quickly identify and fix the issues. Finally, the production line has a 5.2% improvement in UPH and over 5x ROI.

Case 3: Real-Time Error Proofing (Electric Vehicle Assembly)

Watch the Interview: How AI Vision Enables Smart Factory Deployment.

Challenge: Early warranty issues persist due to operators occasionally skipping SOP steps. The MES system monitors steps individually but can’t analyze the full collaborative process, making it hard for engineers to quickly identify if issues stem from tools, materials, or procedures.

Solution with AI vision: AI vision combined with MES and AGVs creates a process error-proofing system. If AI vision doesn’t detect key operator actions, or the MES lacks process data, the AGV won’t release items from the workstation. This approach prevents quality issues at the source, achieving zero early-stage warranty claims.

Table of Contents