By Sursha Wu

PowerArena HOP (Human Operation Platform) is the ultimate AI computer vision solution for real-time production line management. Powered by advanced computer vision technology and proprietary AI models, HOP is designed for manufacturing scenarios, factories, and operational needs.

What we offer

A unified AI-powered computer vision system that delivers accurate SOP compliance tracking, real-time anomaly detection, and actionable insights to boost UPH, reduce downtime, and ensure consistent quality.

With seamless integration, real-time AI vision analytics, and comprehensive video traceability, HOP computer vision software empowers manufacturers to enhance productivity, optimize resource allocation, and build golden-line standards across operations. Experience PowerArena HOP for intelligent production line management, enhanced decision-making, and measurable quality and efficiency gains.

PowerArena HOP (Human Operation Platform) is a computer vision platform for manufacturing. It uses AI computer vision to monitor operations, detect defects, and ensure process accuracy. With vision analytics and artificial intelligence vision, it identifies root causes on the production line and supports faster, smarter decision making.

Connect with us to learn more about PowerArena HOP(Human Operation Platform), powered by AI computer vision.

What is computer vision?

Computer vision uses artificial intelligence to analyze, process, and interpret visual data. It enables machines to “see” and “understand” images like humans do, recognizing objects, humans, and actions.

Common types of AI computer vision recognition include:

Object Detection

More factories are adopting AI computer vision to detect defects on products such as PCBs. Compared to traditional AOI systems, AI computer vision offers higher accuracy and significantly lowers false-positive rates.

Human Detection

- Smart City

AI vision helps count foot traffic and monitor crowd density in areas like stations and malls, supporting public safety and urban planning.

AI vision improves safety by spotting when someone enters a restricted area. It also helps monitor the production line by detecting if a worker leaves their station or if too many people are at a workstation meant for one.

How computer vision platform work in factory?

Behavior Recognition

AI computer vision can recognize worker behavior on the production line in real time. It checks whether each task is carried out according to the correct SOP and spots when any step is missed, done out of order, or takes longer than it should. This helps managers catch issues early and improve both efficiency and quality.

PowerArena’s AI computer vision accurately detects human, objects, and actions. It instantly alerts managers via a platform when operators leave posts too long, abnormal objects appear, or irregular actions occur, ensuring safety and quality.

Bridge the gap between AI potential and real-world execution. Request a demo of PowerArena today.

How computer vision works?

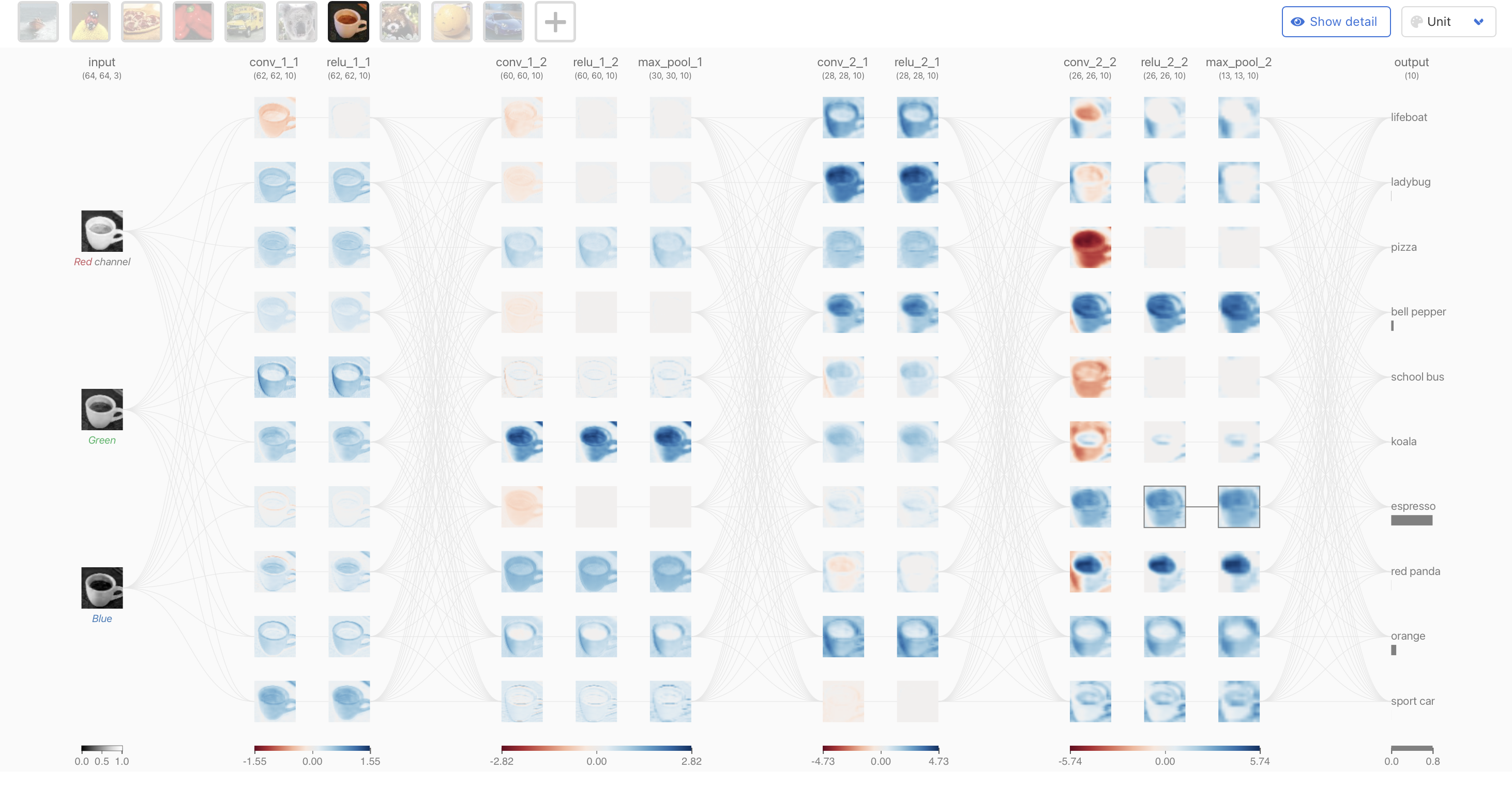

Computer vision uses Convolutional Neural Networks (CNNs), a deep learning method for image analysis and recognition. CNNs break down images into layers, each extracting and refining features like edges, shapes, or patterns. These features are then used to accurately classify objects, such as identifying whether an image shows a bird or an airplane.

Each “layer” of computing units analyzes and processes complex data. Neuron in each layer extracts features from the previous layer and pass them forward for further refinement. Source: CNN Explainer

Why Not Develop Computer Vision Systems from Scratch: Risks You Need to Know

As AI vision technology becomes more widespread and its value is proven in the market, many manufacturers consider adopting AI computer vision software to enhance production quality and efficiency. However, one of the most common questions we hear from manufacturers is:

“Should we build or buy an AI vision system?”

While building in-house might seem cost-effective at first, most teams face long-term challenges with maintenance, scalability, and integration with existing OT workflows. That’s why many companies turn to ready-made AI vision services that are already tested on the factory floor.

Why Use Computer Vision Platform Instead of Building from Scratch?

Partnering with an experienced platform provider allows manufacturers to stay focused on their core operations. Developing the system on your own often leads to costly trial and error, and tools that ultimately don’t meet shop-floor needs.

Top 5 Advantages of PowerArena’s AI Computer Vision Software for Manufacturers

Global Renowned Semidoctor uses PowerArena’s HOP as their computer vision platform.

1. Lower Costs

PowerArena AI vision platform monitors every operation in the factory to ensure it follows standard procedures and remains free from abnormalities. This significantly reduces the number of defective products and the risk of costly customer complaints.

The system records the entire production process and links each video to the specific product ID. When an issue arises, teams can quickly trace the root cause, stop problematic production, and prevent further damage.

2. Improve Yield Rate

PowerArena AI vision platform enables 100% in-process quality control by continuously monitoring every/key step of production. It detects errors in real time and ensures that all operations follow the correct SOPs.

For manual production lines, it acts as a digital IE (Industrial Engineer), helping managers enforce standards and maintain quality across shifts without the need for constant supervision.

PowerArena’s AI vision platform records the entire production process and analyzes errors on the line to ensure quality and efficiency.

3. Improve UPH (Units Per Hour)

Many bottlenecks in production speed are hidden in manual actions or subtle workflow issues that data metrics cannot explain.

By recording the entire production process, PowerArena AI vision platform allows managers to review footage and visually identify problems that were previously overlooked. These insights help streamline operations and significantly boost production efficiency.

4. Rapid Replication Across Global Sites

PowerArena AI vision platform is a software solution that can be deployed across global operations. When factories expand to new locations, the platform supports automated management, real-time monitoring, and instant error correction.

This reduces the need for additional manpower and ensures that new sites maintain the same high standards of quality and efficiency as established facilities.

5. Improve Transparency in Production Line

Centralized platform connects data across all lines and sites, breaking down data silos of different production line and enabling unified production management. Even in global operations, management can remotely access real-time production status with analytics and production data without needing to be on-site, ensuring full visibility for global manufacturers.

Why use HOP (Human Operation Platform)?

HOP (Human Operation Platform) is PowerArena’s AI vision-powered smart manufacturing solution.

Quality

HOP’s AI models deliver confidence levels above 97%

Accuracy is the foundation of AI computer vision in manufacturing.

HOP outperforms many other platforms by delivering high recognition precision. What’s more, with years of factory implementation experience, our team helps customers restructure workflows and align vision deployment with real production goals, driving improvements in both quality and efficiency.

Speed

Our system can go live in as little as four weeks.

Unlike many platforms that require long training cycles, PowerArena offers fundamental models that support fast deployment on the shop floor. HOP already recognizes common objects and actions found in factories—such as PCBs, tools, parts, hands, and heads—so it can start generating value almost immediately.

Agility

HOP is software-based and built for scale.

Unlike typical AI computer vision services that require time-consuming model training before deployment, PowerArena’s computer vision solutions come with foundation models already trained to recognize most objects and scenarios in factories, which helps reduce implementation time.

Also, HOP also allows users to train models further to adapt to variations such as different colors or shapes of objects, providing flexibility in real production environments.

PowerArena HOP enables users to train their AI models without any AI expertise, reaching over 95% confidence in less than 30 minutes.

What’s next

Plan a free consultation today!

Leave your details and we’ll plan a 30-min session.

PowerArena HOP AI computer vision solutions

Level 1: Digital Station

Digital Work Instruction

Provides real-time SOP guidance directly on the workstation, helping new workers perform tasks accurately and with confidence. This reduces onboarding time and ensures consistent execution across shifts.

Production Records

Automatically records and tags key process footage, linking each video to the corresponding product ID. Managers can quickly retrieve records for audits, after-sales support, or internal troubleshooting, speeding up response times while significantly reducing storage costs by saving only the most relevant footage.

Level 2: AI Line Balancing

A well-balanced line can increase UPH by 5.2% and deliver over 5x return on investment.

AI vision automatically collects and analyzes production data 24/7, capturing cycle time, process time, and idle time with precision. Every movement or incident on the line is recorded. Based on the reports, engineers can quickly identify and fix the issues.

Level 3: AI Poka Yoke

Poka Yoke = error prevention

Powered by AI vision, in-line quality control (IPQC) helps maintain over 95% yield and achieve 100% first-pass yield (FPY).

AI vision detects abnormal operations in real time and immediately alerts supervisors. Managers can view the cause and video footage directly from the platform, allowing them to stop the issue before it spreads.

When integrated with MES or IoT systems, AI vision fills in the gaps that traditional data cannot capture, ensuring that no undetected errors reach the market. This prevents defects at the source and supports zero early-stage warranty claims.

Start managing your production the right way.

PowerArena’s Computer Vision Use Cases

Real-Time Management in EMS

PowerArena HOP integrates IoT, MES, and AI vision data into a real-time dashboard, enabling instant visibility of cycle times, operator actions, and anomalies from both manual labor and machines. The unified view helps EMS manufacturers to monitor factory operations in real time and take immediate action on every error.

SOP Compliance in EV & Automotive

Ensuring SOP compliance is critical for EV and automotive assembly lines. PowerArena computer vision solutions monitor every step of the process, ensuring workers follow standard procedures while reducing errors and maintaining high product quality.

Traceability & Quality Control in Semiconductor

Semiconductor manufacturers rely on PowerArena for full traceability and real-time quality control. Any SOP deviation triggers instant alerts to managers. Also, with full production footage recorded, teams can quickly trace root causes, prevent defects, and provide transparent records for audits and customer reviews.

Download Our Clients’ Success Case

FAQ

1. What is computer vision?

Computer vision is an AI technology that enables machines to interpret visual data from cameras or videos. In manufacturing, it’s used for defect detection, SOP compliance, and production monitoring.

2. What are some practical applications of computer vision?

Computer vision is applied in quality control, real-time line monitoring, process traceability, worker safety checks, and automated production data analysis for better decision-making.

PowerArena HOP is a unified computer vision software that brings all these applications into one platform, providing actionable insights and real-time visibility across the shop floor.

3. How can I benefit from PowerArena’s computer vision platform?

- AI Poka Yoke for In-Process Error Prevention

- Data-Driven Decision for Better Management Efficiency

- Continuous Data + Video Collection for Complete Production History

- Digital Work Instruction for Better SOP Compliance

- Consistent Performance Facilitating for New Facility

Curious about how AI vision manages human behavior on the shop floor?

4. Can HOP be integrated with existing production management tools?

Yes. HOP can easily connect with IoT, MES, ERP, and other manufacturing management systems to create a unified, data-driven, and powerful production environment.

5. How does AI vision help manage operations across different lines or factories?

Replicating proven production lines across global sites is challenging, especially when relying on new local talent.

PowerArena HOP AI vision model records and standardizes the proven SOPs of existing plants. These SOPs can be accessed and applied at any location, enabling consistent quality and management practices across all facilities.

PowerArena deployed an AI vision model in a factory within 1 month.

Table of Contents