Introduction

Quality management plays a crucial role in businesses, ensuring that products and services meet standards while also serving as the foundation for improving market competitiveness. However, as the manufacturing environment grows increasingly complex, quality management faces more and more challenges.

In the following sections, we will discuss the challenges of quality management in today’s manufacturing industry and explore solutions. Specifically, we will explain how AI vision technology helps companies enhance their quality management, ultimately achieving the goal of boosting overall business competitiveness.

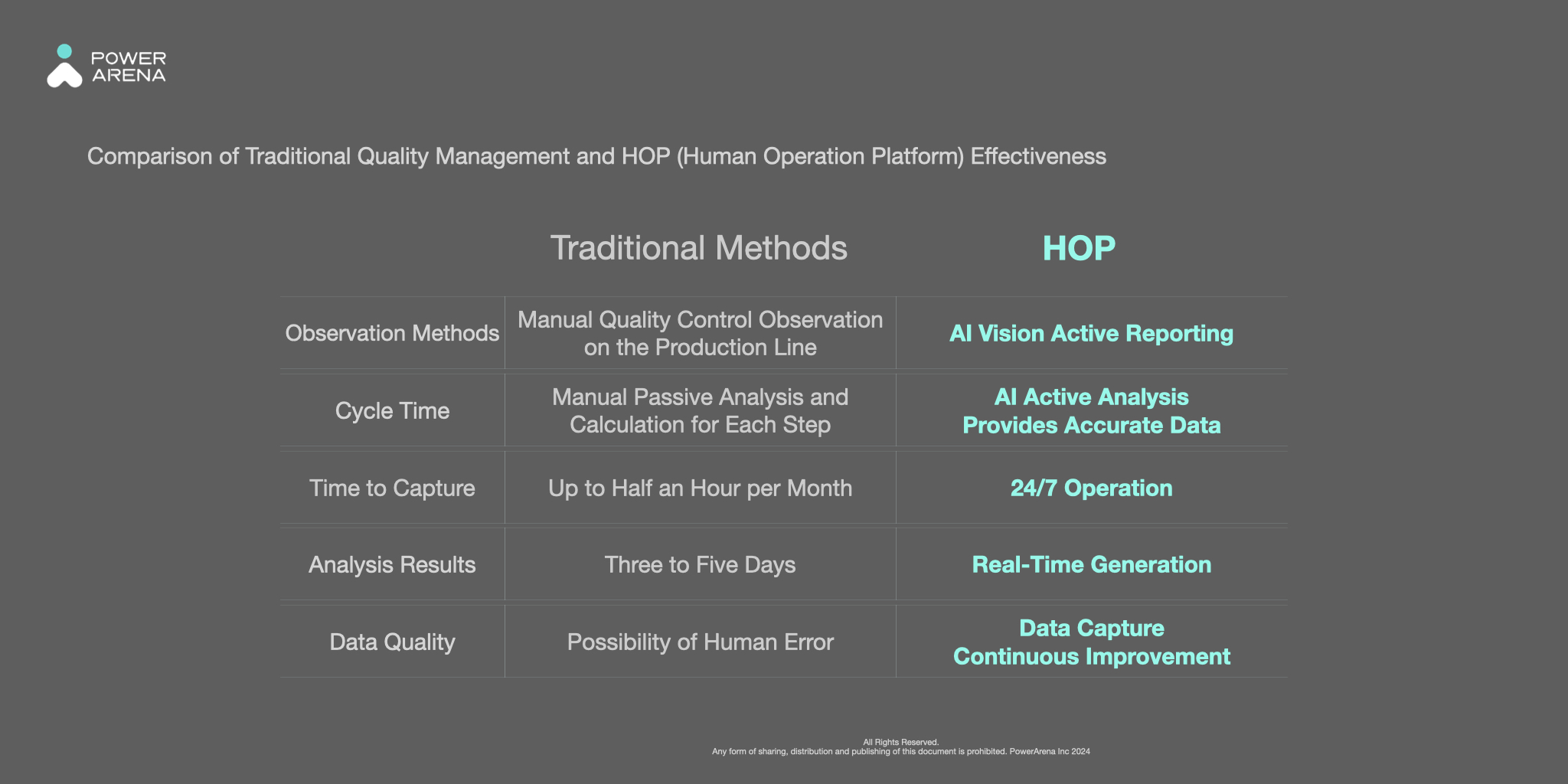

Comparison of Traditional Quality Management and HOP (Human Operation Platform) Effectiveness

What is HOP (Human Operation Platform)?

What is Quality Management?

Quality management refers to a series of activities that ensure products or services meet standards and fulfill customer needs. It includes planning, control, assurance, and continuous improvement. The objective is to improve product quality, reduce errors and waste, enhance customer satisfaction, and strengthen market competitiveness. This leads to cost reduction, increased efficiency, and greater profitability for the business.

Costs of poor quality in a thriving company will be about 10-15% of operations. Effective quality improvement programs can reduce this substantially, thus making a direct contribution to profits.

(source: ASQ)

Key Aspects of Quality Management

The primary goal of quality management is to ensure consistent quality in products or services. Quality management professionals focus on the following three key areas:

-

- Preventing Issues: Identifying potential problems in the production process and taking preventive measures.

-

- Ensuring Continuous Improvement: Using data analysis and feedback mechanisms to constantly optimize production processes and product quality.

-

- Enhancing Customer Satisfaction and Corporate Image: Delivering products that meet or exceed customer expectations.

Achieving efficient quality management is the ideal goal for companies and factories. However, the increasing complexity of production lines presents numerous challenges for quality management professionals.

Common Challenges in Quality Management

- Production Line Complexity: With the rapid advancement of product technology, production processes have become more complex, increasing the difficulty of quality management.

For example, on production lines that rely on human labor, the variability of worker actions is high. Factors like oversight, physical condition, and familiarity with operations can all impact product quality. Managing human behavior, data collection, and root cause analysis often consumes significant time and cost in quality management.

Over 72% of factory tasks are still performed by humans. Robots have yet to fully replace all jobs in our factories. (source: Kearney)

Introducing AI vision technology into production lines can upgrade quality management.

- Changing Customer Expectations: As customer expectations for product quality continue to rise, businesses must consistently improve quality to meet market demands.

- Cost Pressure: While maintaining quality, there’s a need to sustain or even reduce production costs, testing the adaptability of quality management personnel.

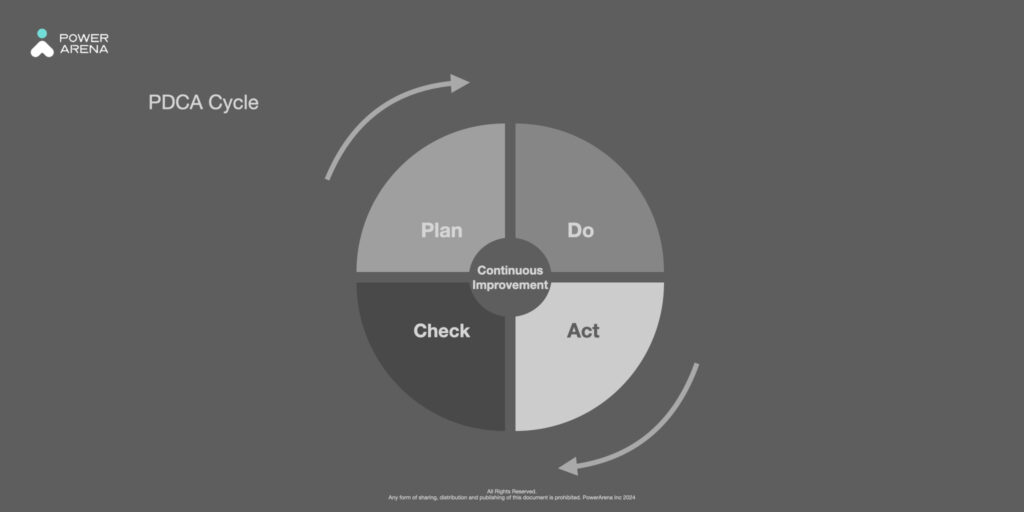

Core of Quality Management – PDCA Cycle

PDCA Cycle

The PDCA Cycle (Plan, Do, Check, Act) is a systematic quality management concept introduced by renowned American management expert Edwards Deming in the 20th century. It provides a structured approach to continuous improvement in quality management.

The process is as follows:

-

- Plan: Define quality standards, goals, and specific requirements, and create an implementation plan.

- Do: Execute the production or service delivery based on the plan, while implementing quality control.

- Check: Inspect and evaluate the effectiveness of quality management using data analysis to identify any issues or deviations.

- Act: Based on the inspection results, make continuous improvements by adjusting processes or strategies to achieve higher quality standards.

After completing one cycle, the results serve as the foundation for setting the next goals, continuing the cycle until the quality management objectives are met.

Effective PDCA cycles rely heavily on comprehensive production line histories and data support.

However, most current quality management methods still depend on manual data collection and inspection, which compromises data reliability and timeliness, weakening the effectiveness of the PDCA cycle.

Introducing AI vision technology into production lines can resolve these challenges.

Application of AI Vision Technology in Quality Management: HOP (Human Operation Platform)

1. Transforming Unstructured Data into Structured Data: Data-Driven Quality Management

In labor-intensive production lines, workers’ actions directly impact product quality and production efficiency.

Traditional quality management systems are ineffective at recording and analyzing human factors, preventing managers from obtaining objective data that provides insight into every detail of the production process.

By introducing AI vision technology into production lines, it is possible to transform unstructured data, such as “worker action footage,” into structured data for analysis.

Cameras deployed on the production line record workers’ actions 24/7. Through AI image analysis, the system identifies the causes of low-quality or inefficient production and logs the time, station (location), and cause of events into the HOP Human Operation Platform management interface.

At the same time, the HOP platform integrates with existing factory quality management systems (such as MES systems), providing quality managers with complete production line data support.

2. Real-Time Production Anomaly Alerts: Efficient Quality Management for Human-Operated Production Lines

Manual inspection of production lines can take up to 48 hours per product to conduct time studies.

In traditional management, quality control personnel’s manual records and analyses often overlook many production line activities. As the number and complexity of production lines increase, the manpower required becomes overwhelming.

By introducing AI vision technology, the system can verify whether workers are following the production SOP (Standard Operating Procedure). When AI detects abnormal actions, it immediately notifies management, preventing rework, waste, and inefficient production time.

AI vision technology assists in data collection and analysis, allowing quality control personnel to focus on higher-value decision-making and planning.

The real-time inspection and automated alert features improve production line efficiency and quality, reducing unnecessary costs and achieving the three critical goals of lowering production costs, reducing resource waste, and increasing production efficiency.

3. Complete Production History: Quality Management for Continuous Improvement

In traditional quality management methods, quality managers often lack solid evidence to prove the effectiveness of corrective measures, delaying improvement progress and reducing management confidence.

The HOP Human Operation Platform collects and analyzes a large volume of operational data, recording the entire production history. It provides decision-makers with production history footage and data analysis. Quality managers can trace back AI-tagged problem footage to accurately identify bottlenecks.

With clear “evidence,” managers can optimize production plans, precisely address the root causes of low quality and inefficiency in the production process, thereby effectively removing obstacles and increasing UPH on the production line.

The Five Quality Management Tools

The Five Key Quality Management Tools

-

- SPC (Statistical Process Control): SPC uses statistical tools to identify abnormal fluctuations in the production process. Through data analysis, SPC quickly detects and adjusts abnormalities to restore production line stability, preventing defects and inefficiencies.

For manufacturing production lines, effective control of production factors and real-time anomaly alerts and responses are core objectives of SPC.

-

- FMEA (Failure Mode and Effects Analysis): FMEA is used to identify potential failure modes and risks in the production process before mass production, finding root causes and implementing preventive measures to avoid major losses after production begins.FMEA is divided into two types:

- DFMEA (Design FMEA): Focuses on analyzing potential failure situations that may arise before production begins, such as low production efficiency or decreased customer satisfaction, and devising solutions.

- PFMEA (Process FMEA): Focuses on existing production line plans, identifying failure modes in the production process, such as workers not following the required SOPs or the inability to improve product yield. It aims to find and address production issues that lead to these failure modes, ensuring process stability.

- FMEA (Failure Mode and Effects Analysis): FMEA is used to identify potential failure modes and risks in the production process before mass production, finding root causes and implementing preventive measures to avoid major losses after production begins.FMEA is divided into two types:

Whether in predicting problems or improving production processes, real-time understanding of current production line conditions and ensuring yield improvement are the core objectives of FMEA.

A quality management tool achieves a high yield.

Redefining Quality Management: More Efficient, Flexible, and Intelligent

Even the world’s leading semiconductor companies continue to face the same quality management challenges:

How can we detect errors faster, reduce costs, and improve product quality?

In the era of smart manufacturing, many businesses have realized that traditional quality management methods are inadequate for handling the complexities of modern production lines.

Abandoning conventional methods and embracing AI vision technology is the key to breaking through bottlenecks and giving companies a competitive edge.

PowerArena’s HOP (Human Operation Platform) helps you achieve:

-

- Real-time defect detection and rapid response

-

- Proactive identification of operational anomalies to improve production efficiency

-

- Precise data analysis for optimized decision-making

HOP redefines your quality management, giving you a significant advantage in the market!

Quality Management Tools Used by Leading Semiconductor Manufacturers

A global semiconductor leader specializing in precision manufacturing provides key components for the high-tech industry. Its value lies in complex processes and fine craftsmanship.

Maintaining high yield is the top priority of quality management. Any oversight in details results in the cost of rework, material waste, and potentially damaged brand reputation.

To improve the efficiency and effectiveness of quality management, the company implemented PowerArena’s HOP (Human Operation Platform) for its photomask box assembly station, helping quality managers monitor manual processes.

Within six months of implementing the HOP platform, the station maintained a stable yield rate of 95% and a throughput rate of 97.6%.

AI vision technology continuously monitors the production line, detecting and alerting anomalies, and correcting errors in real-time. Through AI image analysis, the platform fills in gaps in production line data. Assembly errors are eliminated, and production line yield is significantly improved, truly achieving efficient quality management.