By Sursha

Quality management plays a critical role in ensuring that products and services meet quality and productivity goals while serving as a foundation for strengthening market competitiveness. However, as manufacturing becomes more distributed, with factories relocating to new sites or countries, maintaining consistent quality and efficiency has become increasingly challenging.

Differences in workforce skills, process maturity, and oversight often lead to performance gaps. In this environment, modern quality management tools and software are essential. They not only help you standardize processes but also capture and transfer manufacturing data and know-how across sites, ensuring consistency and efficiency.

In this article, we share:

/What is AI-powered quality control software?

/How can I ensure consistent quality across human and machine-operated workstations?

/How do I standardize quality and productivity in different factory locations?

/What quality management software can I use for replicating manufacturing know-how from our original factory to the new one?

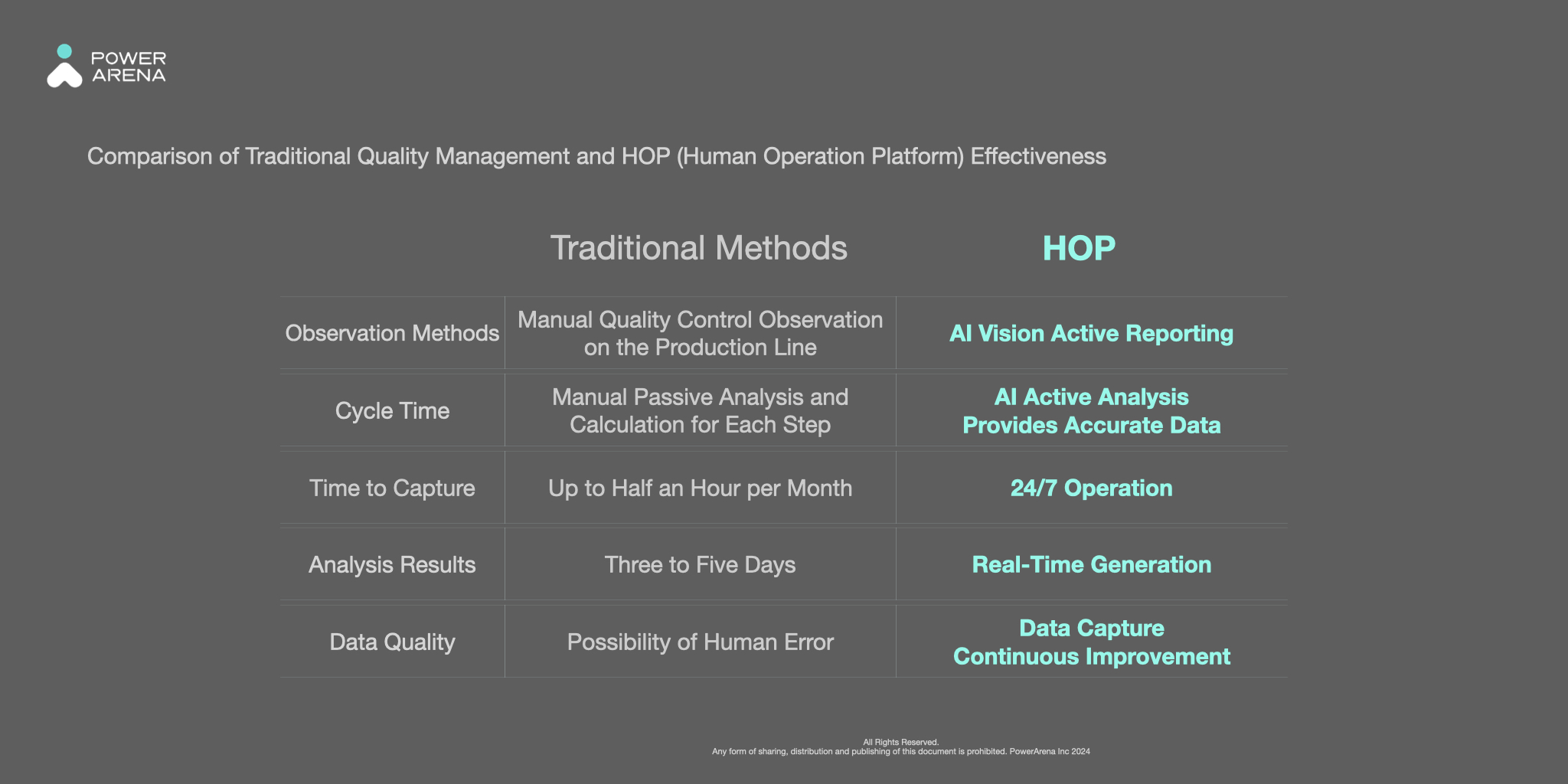

Comparison of Traditional QMS Software and HOP (Human Operation Platform) Effectiveness

What is Quality Management?

Quality management refers to a series of activities that ensure products or services meet standards and fulfill customer needs. It includes planning, quality control, quality assurance, and continuous improvement.

The objective is to improve product quality, reduce errors and waste, enhance customer satisfaction, and strengthen market competitiveness.

Costs of poor quality in a thriving company will be about 10-15% of operations. Effective quality improvement programs can reduce this substantially, thus making a direct contribution to profits.

(source: ASQ)

How to Strengthen Quality Management: 3 Key Areas to Focus On

The primary goal of quality management is to ensure consistent quality in products or services.

Implementing quality control software can meet the following goals:

-

- Preventing Issues: Identifying potential problems in the production process and taking preventive measures.

-

- Ensuring Continuous Improvement: Using data analysis and feedback mechanisms to constantly optimize production processes and product quality.

-

- Enhancing Customer Satisfaction and Corporate Image: Delivering products that meet or exceed customer expectations.

Top 3 challenges in quality management(2025-2026)

1. Human Errors Are Hard to Catch in Time

In factories that rely heavily on manual labor, human variability makes real-time quality control difficult. Factors like operator fatigue, unfamiliarity with SOPs, and simple oversight often lead to defects. Without the right quality tools, collecting accurate data and identifying root causes takes too much time and effort, making effective quality assurance hard to sustain.

All the operators’ behavior can me track on the shop floor and alart all the SOP/Movement deviations on the management dashboard.

Common query: How can I improve quality control on a manual production line?

2. Lack of Skilled IE Talent for Global Factory Expansion

Due to shifting tariffs and policy changes, more manufacturers from China, Taiwan, and Europe are setting up new factories in the U.S. or Southeast Asia. However, without the original domain know-how and experienced industrial engineers, it’s difficult to standardize operator workflows or apply proven quality management methods. This often results in lower productivity and inconsistent quality outcomes.

Common query: How do I maintain quality when expanding to a new factory site?

3. No Unified System for Managing Human and Machine Data

Today’s production lines involve both machine automation and manual operations. But most factories still lack a centralized quality system software that integrates data from IoT devices, MES systems, and human actions. Without real-time insights, managers waste hours gathering and analyzing scattered data, missing the chance to prevent downtime or identify stations with cycle time overruns.

Common query: What quality system software can integrate machine and manual data in real time?

Have a challenge? PowerArena has the solution

PowerArena’s Human Operation Platform (HOP) offers an all-in-one quality control solution, covering operator training, AI-powered IPQC (In-Process Quality Control), real-time machine and data integration, and an AI Agent/LLM-driven industrial engineering knowledge base.

Get in touch to request a live demo and personalized pricing for your factory.

AI-powered quality software: HOP (Human Operation Platform)

HOP (Human Operation Platform) is PowerArena’s AI-powered solution designed to support agile quality management in modern manufacturing.

As a comprehensive quality management system software, HOP integrates AI vision, real-time monitoring, and production video traceability to unify data collection, SOP compliance, and quality control into a single platform. This all-in-one quality software helps manufacturers ensure consistency, reduce errors, and replicate best practices across facilities.

Improving Operator Training with Digital Quality Management Tools

HOP automatically delivers station-specific digital work instructions based on the assigned SKU. These can include text, images, and videos, and support auto-play or interactive navigation.

Unlike paper or Excel-based SOPs, this digital method improves update efficiency and allows operators to instantly reference the latest standard procedures, reducing errors and missed steps.

For factories with frequent changeovers, HOP shortens onboarding, lowers the learning curve, and stabilizes workflows, resulting in higher quality and efficiency.

Using AI vision to automate time and motion studies and improve line balancing

HOP uses AI vision to monitor operator actions in real time, automatically recording critical production data(like takt time, cycle times, process time, etc.) and pinpointing inefficiencies. This automation replaces manual stopwatch methods, enabling precise time and motion studies for manufacturing and fabrication floors. With accurate, continuous data, managers can optimize line balance, improve resource allocation, and maintain smooth production flow.

How Global Top 5 EMS use HOP to automate their time and motion studies?

Integrating Machine and Manual Data in a unified dashboard

HOP unifies IoT machine data, MES outputs, and manual operation metrics in a single real-time dashboard. This eliminates fragmented data and gives managers instant visibility into production health, helping them act quickly to maintain quality standards.

Achieving 100% Production Traceability in Manufacturing

Within six months of implementing AI vision systems, overall UPH (Units Per Hour) on the production line increased by 19%.

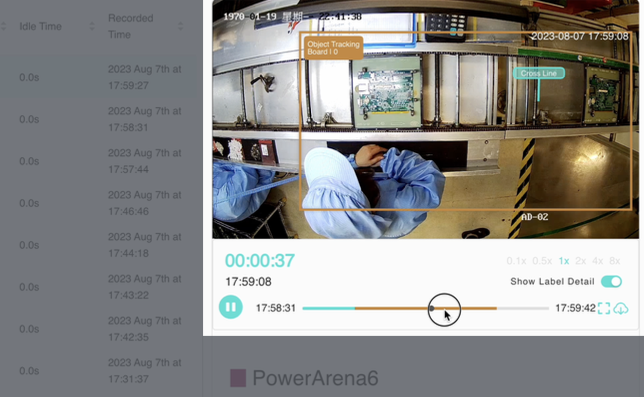

HOP Human Operation Platform collects and analyzes a large volume of operational data, recording the entire production history. HOP provides decision-makers with production history footage and data analysis. Quality managers can trace back AI-tagged problem footage to accurately identify bottlenecks.

With 24/7 recording of the production, HOP allows engineers to track and trace abnormal events with clear and real-time production video.

Ensuring SOP Compliance and Detecting Behavior Deviations in Real Time

HOP is powered by AI computer vision technology, which can recognize worker behavior on the production line in real time. It checks whether each task is carried out according to the correct SOP and spots when any step is missed, done out of order, or takes longer than it should. This helps managers catch issues early and improve both efficiency and quality.

Situations such as leaving the workstation or exceeding standard operation time are automatically detected by AI vision and reported to the line supervisor. Video footage: Compal’s POC demonstration line.

Leveraging AI Agents and LLMs to Gain Instant Quality Analysis for Factories

In traditional manufacturing, information/data silos between production lines and sites often slow decision-making.

AI Agent in PowerArena’s HOP platform integrates MES, ERP, IoT, and AI vision data, combining it with the factory’s accumulated know-how for fast, accurate analysis.

Managers can get real-time production insights through a guided Q&A interface, while the AI Agent recommends targeted actions for bottlenecks or quality issues, significantly speeding up response times.

Unlike standard AI chatbots (like ChatGPT, Gemini, and others), PowerArena’s HOP AI Agent:

- Operates on-premise to ensure maximum data security.

- Learns and applies your factory’s domain knowledge and quality standards, enabling operators and line managers to get accurate, context-aware recommendations.

- Provides prompt-free interaction with pre-designed questions from PowerArena, so managers can simply click to query the LLM instead of typing prompts, making it faster and easier to use.

Want to see how AI Agents can transform your factory’s quality management?

Learn how PowerArena can help you achieve perfect product quality

Request a demo to see how our quality platform can help your manufacturing

PowerArena’s HOP records the entire production process and analyzes errors on the line with AI vision to ensure quality and efficiency.

Case Study: How a Semiconductor Manufacturer Achieved FPY 97.6% with AI-powered Quality Software

Within six months of implementing the HOP quality control solution, the station maintained a stable yield rate of 95% and a throughput rate of 97.6%.

A global semiconductor leader specializing in precision manufacturing provides key components for the high-tech industry. Its value lies in complex processes and fine craftsmanship.

Maintaining high yield is the top priority of quality management. Any oversight in details results in the cost of rework, material waste, and potentially damaged brand reputation.

To improve the efficiency and effectiveness of quality management, the company implemented PowerArena’s HOP (Human Operation Platform) to manage its packaging workstation and ensure SOP compliance.

Table of Contents