By Sursha

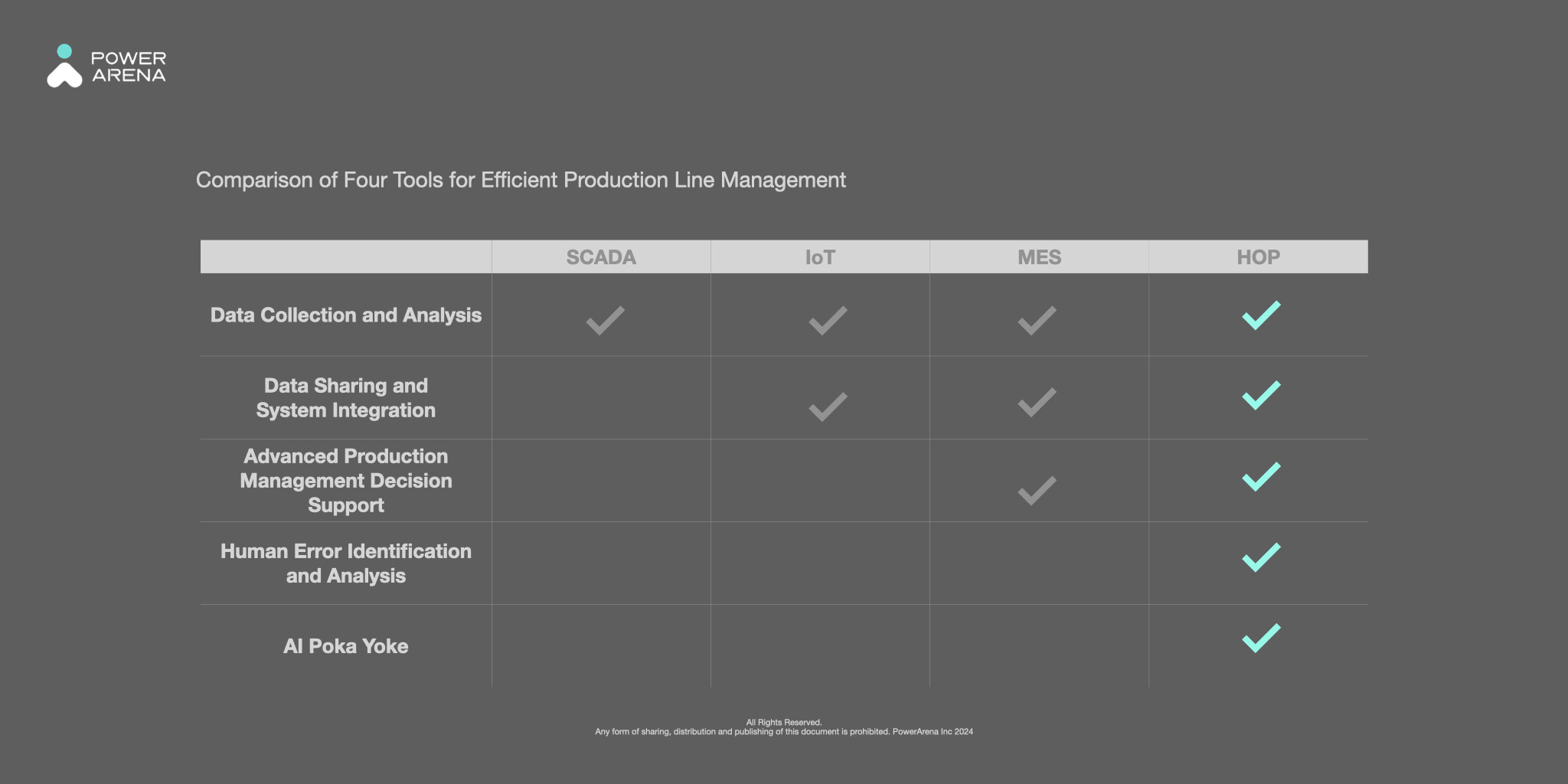

Improving quality and increasing UPH (Units Per Hour) are top priorities for modern manufacturers. A well-designed production management system helps streamline workflows, monitor cycle times, and identify bottlenecks that affect throughput.

With advanced manufacturing management software, companies gain real-time visibility into every stage of production, enabling data-driven decisions that boost efficiency and maintain quality standards. From IPQC (In-Process Quality Control), production management solutions ensure that each process is optimized for maximum output.

What is a Production Line?

A production line is a series of orderly workstations where personnel perform specific production activities following a standard operating procedure (SOP) to transform raw materials into final products.

What Does Production Line Management Involve?

Production line management encompasses all resources, equipment, labor, and SOPs involved in the manufacturing process. The goal is to ensure products are produced efficiently according to the plan while maximizing resource utilization, minimizing costs, and maintaining consistent product quality.

Use AI to achieve fast and efficient automated line management.

Key Objectives of Production Line Management with Modern Manufacturing Systems

Boosting Production Efficiency with a Production Management System

A production management system provides real-time visibility into workflows, helping manufacturers streamline processes, reduce downtime, and improve throughput across the production line.

Controlling Costs Through Manufacturing Management Software

Manufacturing management software helps track expenses, optimize material usage, and reduce waste, enabling companies to manage production costs more effectively.

Enhancing Resource Utilization with Software for the Manufacturing Industry

Modern software for the manufacturing industry ensures better scheduling, resource allocation, and equipment utilization, resulting in improved productivity and reduced inefficiencies.

Challenges in Production Line Management

1. Human Operational Errors

Modern manufacturing production lines still rely on human operators. However, manual assembly and inspection by production line workers can often lead to errors that deviate from the SOP, negatively impacting production efficiency and product quality

80% of unplanned downtime is attributed to human error.

(Source: Worldmetric.org.)

2. Quality Control Challenges

As production lines become more complex and variable, coordinating different processes becomes increasingly challenging. Quality control personnel may struggle to track and address abnormalities in each production stage promptly, increasing the risk of undetected defects and delayed corrective actions.

3. Lack of Real-Time Data Support

Traditional production lines require manual data collection, consolidation, and analysis before making meaningful adjustments. Delayed data analysis in response to ongoing production issues leads to lower production efficiency and reduced market responsiveness.

To achieve efficient production line management, start with these four key steps:

4 Steps to Increase UPH and Streamline Production Line Management

1. Standardized Human Work

Many factories still rely on workers to pass down processes through verbal instructions and hands-on training, which leads to inconsistent SOPs based on habit rather than accuracy.

Without a proper production management system, tasks are often performed differently by operators, resulting in skipped steps, quality issues, and slower production, especially for new staff. On long and complex lines, these inconsistencies reduce overall efficiency.

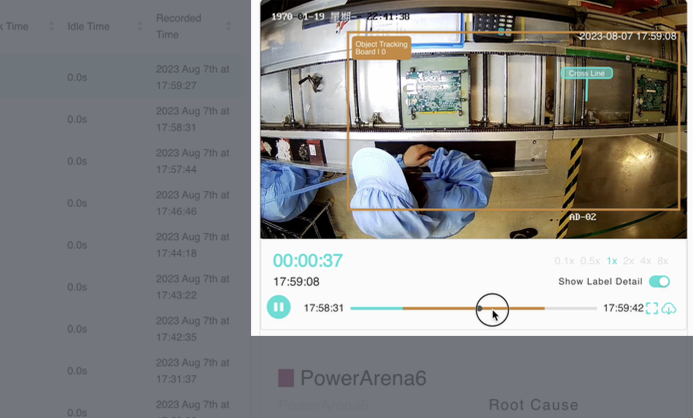

An AI vision-powered manufacturing management software helps capture and analyze operator movements, posture, and part placement. This data helps create SOPs aligned with actual line operations rather than assumptions.

The AI vision system also performs real-time checks to ensure every step is followed. If an error or skipped step occurs, the system automatically sends alerts to managers. Repeated issues generate actionable insights, enabling teams to update SOPs or improve training.

Situations such as leaving the workstation or exceeding standard operation time are automatically detected by AI vision and reported to the line supervisor. Video footage: Compal’s POC demonstration line.

Want to see how AI vision integrates with production management software?

2. Enable Real-Time Monitoring

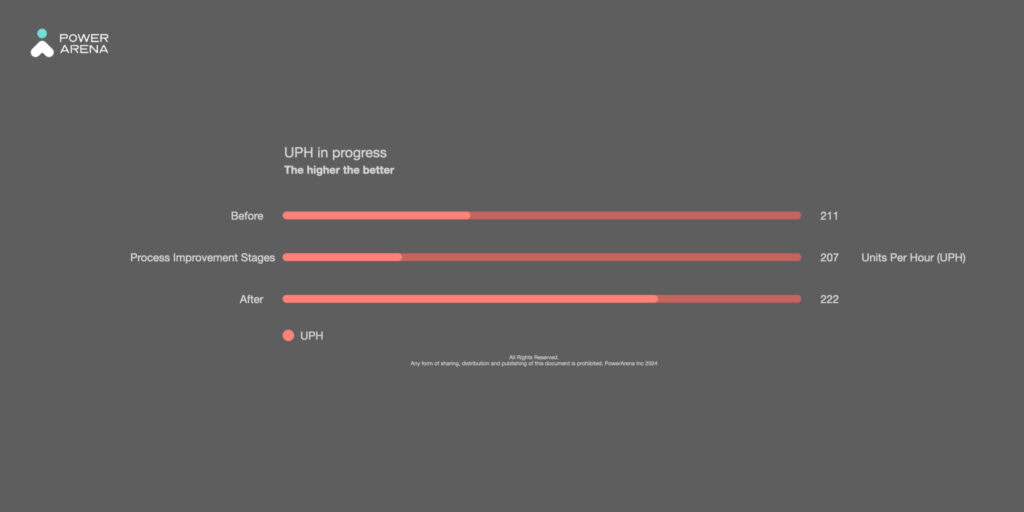

In just four weeks, AI vision boosted UPH by 5.2% and delivered over 5x ROI.

By adopting production line management software integrated with AI vision, factories gain continuous video data and real-time analysis. Engineers can easily visualize every workstation, spot anomalies, and adjust processes faster using actionable insights. This technology eliminates the guesswork and supports data-driven decisions that boost UPH and quality.

Table of Contents