By Sursha Wu

Want to improve line balancing in your factory?

This guide breaks down what line balancing really means, why it’s a cornerstone of lean manufacturing, and how today’s AI—especially AI vision—can transform the process.

From spotting hidden bottlenecks and tracing root causes automatically to cutting idle time and boosting throughput, you’ll see how line balancing software powered by AI creates smoother, more efficient workflows for industrial engineers when improving the line.

You’ll also see how the global top 5 EMS are already achieving results with PowerArena’s line balancing solutions, giving you practical steps and proven examples you can apply on your own shop floor.

This blog is for:

- Production managers seeking to optimise shop floor efficiency

- Industrial engineers looking to implement smart line balancing techniques

- Operational leaders exploring AI-driven manufacturing improvements

- Continuous improvement teams focused on lean transformation

What is Line Balancing?

How can EMS factory boost 5.2% UPH with PowerArena AI software solution?

Line balancing means organizing tasks across a production line so that every workstation keeps pace with takt time—the speed needed to meet customer demand.

When a line is balanced, work flows steadily without long waits, idle stations, or process bottlenecks. This approach is a core principle of lean manufacturing, helping factories boost output, cut waste, and raise overall efficiency.

Today, AI-powered tools like AI vision systems make line balancing easier than ever. They provide real-time visibility, track performance data automatically, and suggest smarter task adjustments to keep production running smoothly.

Benefits of Production Line Balancing

- Prevent Bottlenecks

Balanced lines maintain consistent workflow, reducing delays caused by overloaded workstations and ensuring smoother operations.

- Reduce Waiting Waste

Line balancing minimizes idle time for both machines and operators, ensuring efficient use of resources and reducing unnecessary downtime. For example, reassigning tasks between stations can eliminate waiting periods for workers or machines.

- Minimize Inventory Waste

Balancing production lines helps reduce excess inventory and work-in-progress, freeing up capital and aligning production more closely with actual demand.

- Meet Customer Demands Efficiently

By maintaining a balanced line, manufacturers can meet customer demand promptly, reducing lead times and improving overall satisfaction.

- Increase Flexibility

A well-balanced line allows for quick adjustments to fluctuations in demand, ensuring that production can adapt efficiently to changing circumstances.

- Boost Profit Margins

With optimized use of labor and equipment, line balancing reduces operational costs, maximizing productivity and profitability while minimizing waste.

How to Achieve Effective Line Balancing in Manufacturing

1. Calculate Takt Time

Determine takt time by dividing available working time by the rate of customer demand. This serves as the benchmark for your production line’s performance.

Takt Time=Customer Demand/Available Production Time

Example:

If you have 8 hours (or 480 minutes) available for production and the customer demand is 120 units, the takt time would be:

Takt Time=480 minutes/120 units=4 minutes per unit

2. Perform Time Study

Measure the cycle time of each task using stopwatches, IoT sensors, or AI vision. This reveals workload imbalances and shows where improvements are needed.

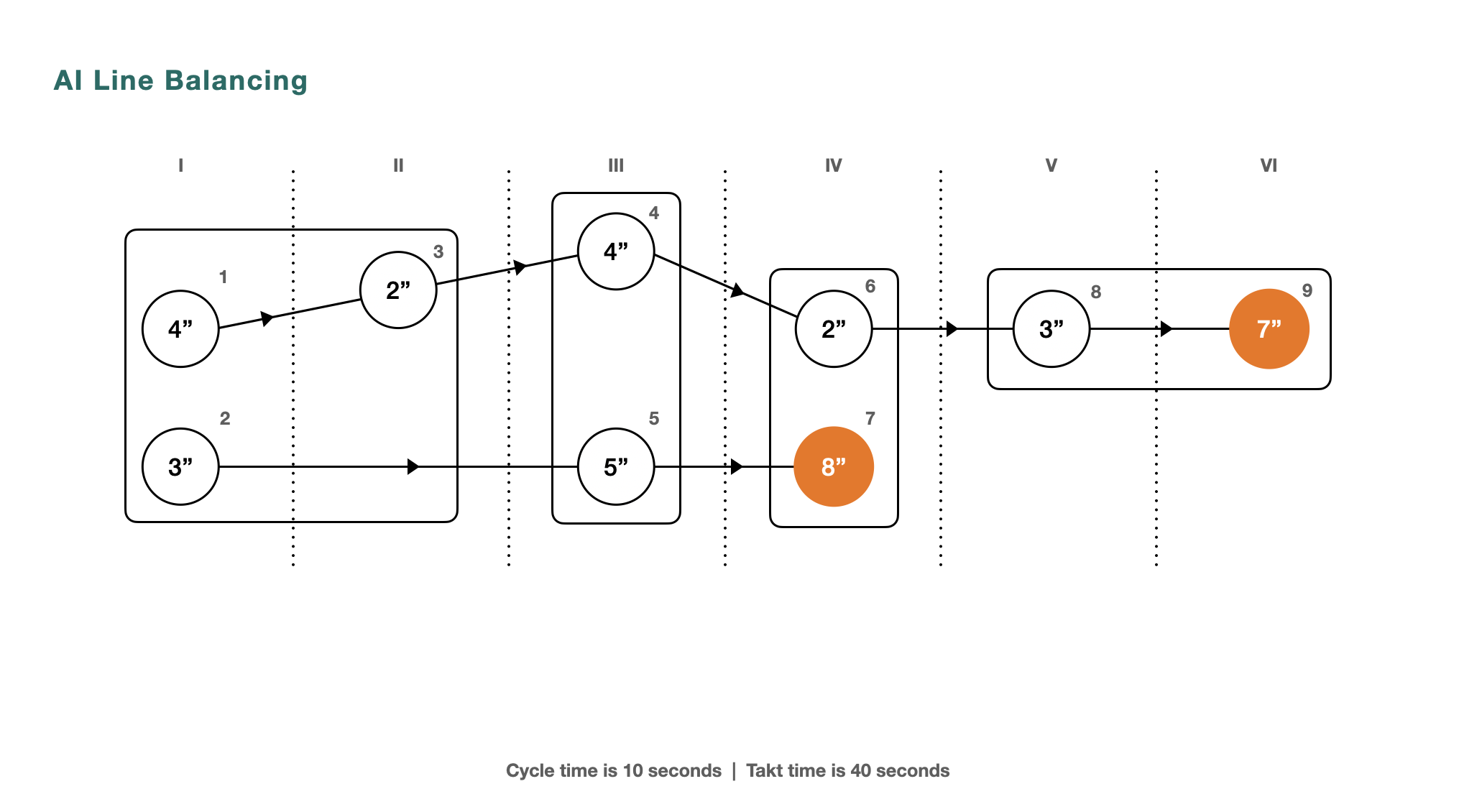

AI Line Balancing

This image shows a typical line balancing setup with tasks spread across six stations (I to VI), each labeled with time in seconds. Arrows indicate task flow and dependencies, while orange circles mark bottlenecks—tasks that take longer (8” and 7”).

Line balancing helps evenly distribute workloads to reduce idle time and delays. Even with parallel task paths, longer tasks like Task 7 can slow the entire line. A 10-second cycle time keeps operations in sync and aligned with the 40-second takt time to meet demand efficiently.

3. Identify Bottlenecks and Excess Capacity

Balanced production starts with finding bottlenecks—stations running over takt time—and areas with extra capacity.

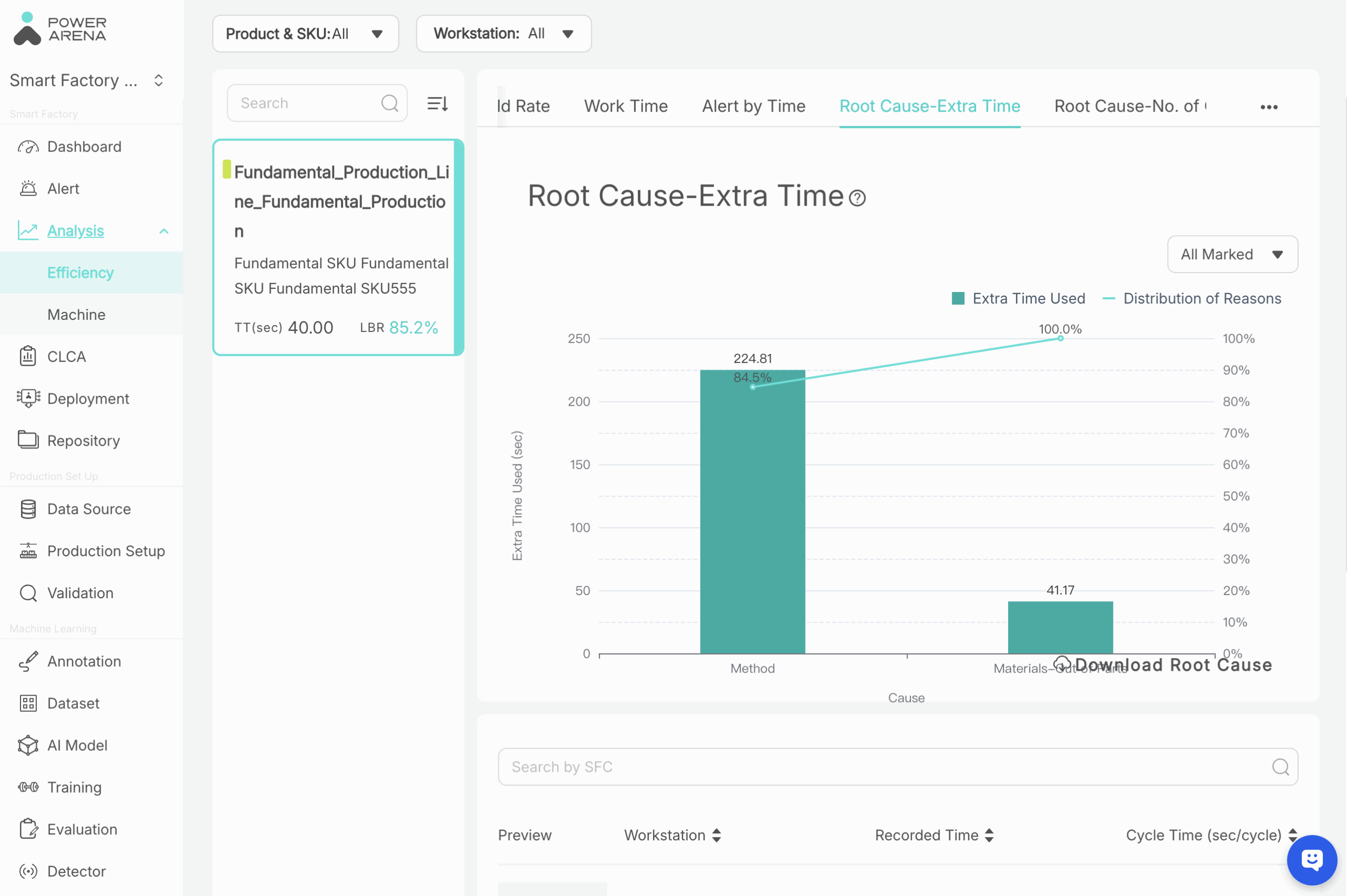

With PowerArena’s AI vision, this happens automatically. The system tracks cycle time, process time, and idle time 24/7, then delivers real-time reports and alerts when a workstation exceeds standards.

Instead of manually monitoring lines, engineers get instant notifications, with every issue logged by time, station, and cause. Video and data records make it simple to replay events, trace the root cause, and take action quickly.

By automating these tasks, PowerArena AI vision saves time, improves transparency, and speeds up line improvements.

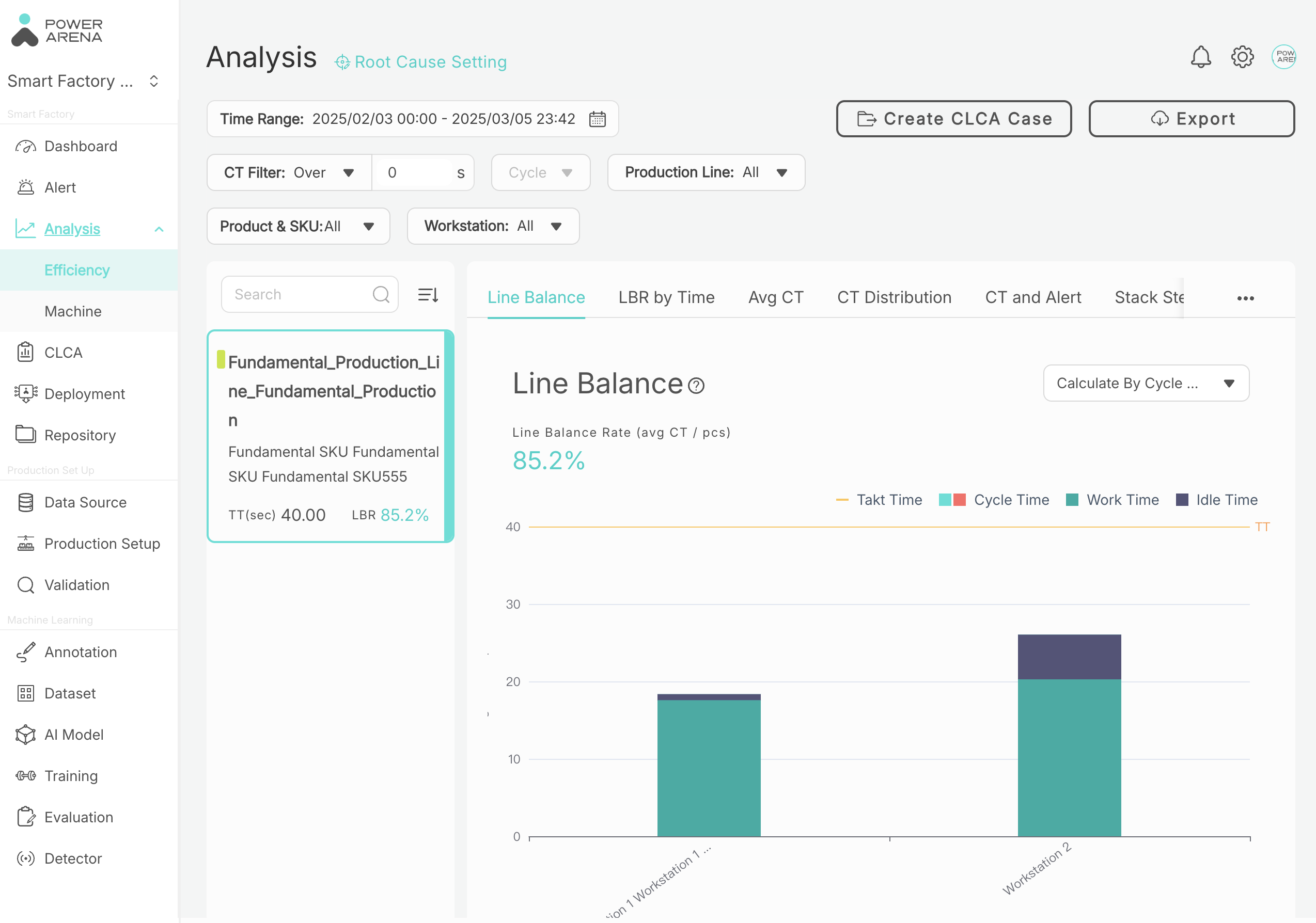

PowerArena AI vision collects and analyzes key production line data, such as cycle time and work time. The visualized production reports enable managers to quickly grasp the current production status.

4. Reallocate Tasks and Resources:

Restructure task assignments to better balance the line. Prioritise task sequence and operator capability. In manual lines, this may require re-training or SOP updates.

Top 5 global EMS use PowerArena AI Vision to cut non-value-added activities by 70%, boosting UPH by 5.2% and achieving 5× ROI.

5. Implement Continuous Improvement

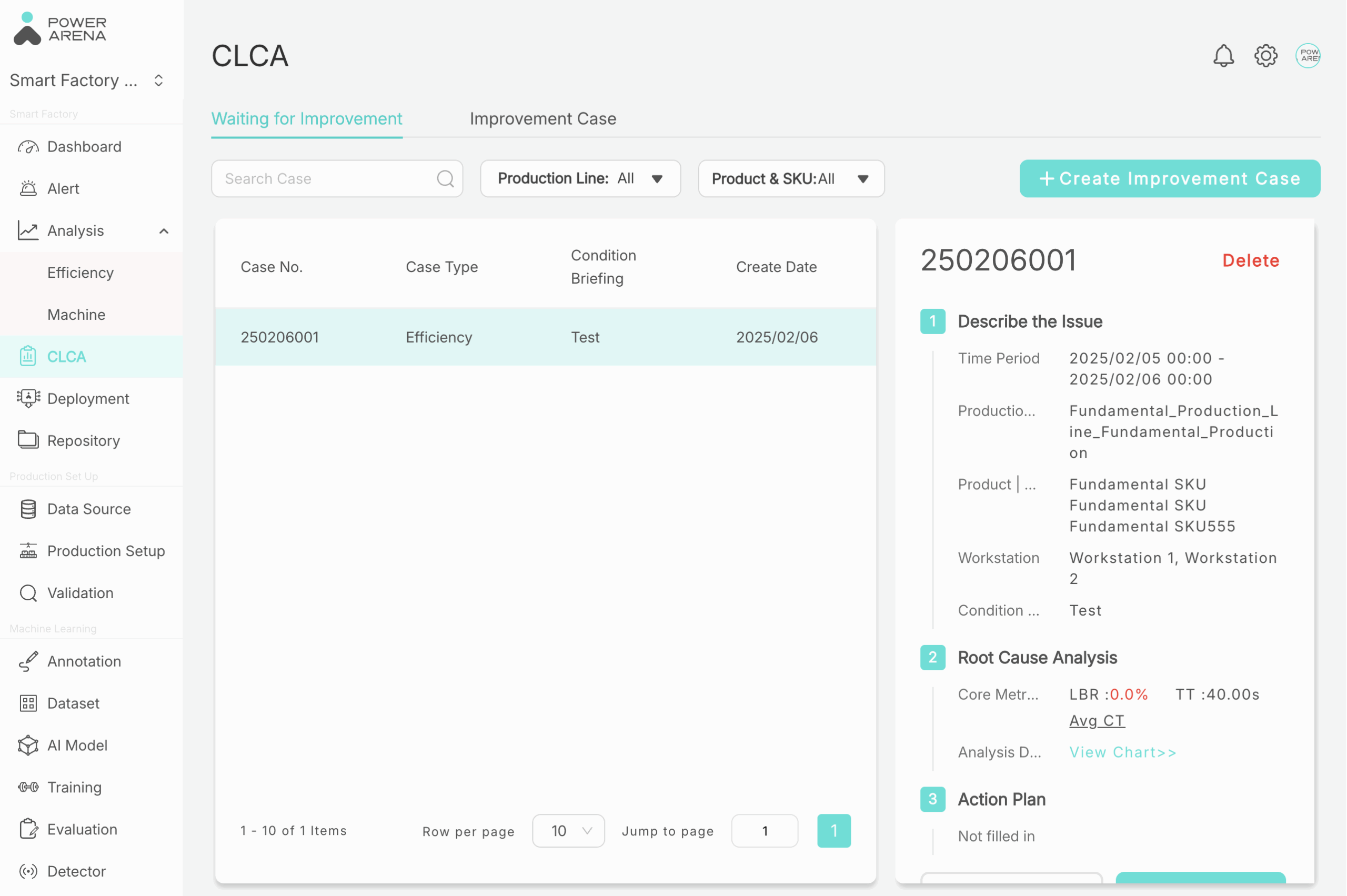

PowerArena dashboard supports CLCA recording and tracking, allowing industrial engineers not only to identify root causes but also to document improvement methods on the platform. This facilitates follow-up tracking of results and serves as a knowledge base for future process improvements.

PowerArena CLCA features.

How can we improve your line balancing with AI software?

PowerArena’s AI vision software

PowerArena AI Vision software monitors assembly production 24/7. If a workstation exceeds the standard cycle time, the line manager or industrial engineer sees an instant alert on the dashboar and can view video of the idle or delayed process.

Struggling with line balancing analysis? Let AI Do the Work.

AI vision systems automatically collect and analyze cycle time and process time across each workstation. The data is visualized in real time, giving managers a clear view of line performance. When a station exceeds the standard cycle time, the system immediately alerts line managers or industrial engineers and pinpoints the root cause behind the slowdown.

PowerArena AI vision solutions help factories cut idle time, fix problems faster, and maintain balanced workflows.

AI vision can automatically identify the root causes of low efficiency and generate real-time reports, uncovering hidden bottlenecks on the shop floor and enabling line engineers to act on improvements faster.

Improving Line Balancing Efficiency with PowerArena AI Vision

- Real-time data tracking: AI vision captures live cycle time, operator activity, and machine usage from every workstation.

- Automatic bottleneck detection: When tasks exceed takt time or operators fall idle, the system flags delays immediately and highlights the root cause.

- Dynamic task reallocation: The system recommends task redistribution between stations to maintain flow and balance. This is especially useful when some stations are overloaded and others underused.

- Workstation behavior analysis: AI vision monitors operator motion and task precision to identify training needs or inefficiencies that affect throughput.

- Operational flexibility: The system adapts to takt time changes, schedule shifts, or product mix variations in real time—helping maintain balance under varying production conditions.

Case Study: How AI Vision Helped Balance the Line and Boost Output

A leading EMS factory in Southeast Asia faced ongoing issues with unbalanced workflows and hidden inefficiencies—until they adopted AI vision technology.

Without full-time monitoring, production managers had no clear view of where delays were happening. Operators frequently left workstations, tools malfunctioned, and upstream issues created unexpected idle time. The result? Lower productivity and limited visibility for improvement.

Inside This Case Study, You’ll Learn:

- How the factory uncovered 20% hidden idle time without adding sensors or new machines

- What caused frequent line interruptions—and how AI vision caught them in real time

- How a simple shift in task allocation led to a 5.2% UPH boost across the line

How can PowerArena’s AI line balancing help you?

Effective line balancing is the foundation of a smooth, efficient production line—and AI vision is the key to mastering it.

PowerArena’s AI vision helps manufacturers gain real-time visibility into human and machine operations, automatically detect bottlenecks, and rebalance tasks with data-backed precision.

By continuously tracking workstation activities and cycle times, PowerArena empowers production teams to reduce waste, improve UPH, and maintain optimal flow. The result: faster response to on-site issues, better use of manpower, and a more agile production line.

Want to see how AI vision transforms line balancing on the shop floor?

FAQs

Q1: What is line balancing, and why does it matter in manufacturing?

Line balancing is the process of distributing tasks evenly across all workstations to match takt time and ensure a smooth production flow. It helps eliminate bottlenecks, reduce idle time, and maximise resource efficiency. For manufacturers aiming to improve throughput and reduce costs, effective line balancing is a core lean strategy.

Q2: How can I identify if my production line is unbalanced?

An unbalanced line often shows signs like operator idle time, queues of semi-finished products, missed takt time, or inconsistent output. Time studies, manual observation, or digital tools like AI vision systems can help pinpoint imbalances and inefficiencies in real time.

Global Top 5 EMS Company Balanced its Line with AI Vision

Q3: What are the main methods to improve line balancing?

Common line balancing methods include:

- Conducting time and motion studies

- Calculating takt time accurately

- Reallocating tasks based on cycle time

- Introducing standardised work and visual controlsDigital solutions like AI-powered platforms can continuously monitor task durations and suggest adjustments dynamically.

Q4: Can AI really help with line balancing?

Yes.

AI vision systems can track each workstation’s performance, monitor operator movements, and collect real-time cycle time data. These insights help managers identify bottlenecks immediately, adjust workloads, and maintain line balance without relying on manual checks.

Q5: What’s the first step to start improving line balancing with AI?

Start by defining your takt time and collecting current cycle time data for each station. Then, implement an AI vision line balancing system that can visualise task flows, track operator actions, and suggest real-time reassignments to balance workloads effectively. No major layout changes are needed—just better visibility and data-driven decisions.

Table of Contents