AI Vision in Southeast Asian Manufacturing: Enabling Global Remote Management and Golden Line Deployment.

In This Report, You’ll Learn:

-

How a factory in Vietnam used AI to rapidly close a major productivity gap.

-

How a Malaysian semiconductor plant leveraged AI vision for real-time error-proofing.

-

How a Thai EV manufacturer built real-time SOP enforcement and a scalable cross-border management model.

First-Hand Insights from Southeast Asia’s Manufacturing Frontlines

From Vietnam to Malaysia and Thailand, PowerArena has worked closely with frontline teams to understand the real challenges faced by factory managers—from ineffective training and production bottlenecks to persistent quality issues.

Despite different symptoms, they all point to the same core questions:

How can manufacturers effectively replicate proven practices from Taiwan and China, while maintaining efficiency and quality in new Southeast Asian plants?

As factories expand and relocate faster than ever, how can manufacturers maintain real-time visibility and remote management across sites?

Proven Results from Real Deployments

This report goes beyond trend analysis. It compiles field-proven use cases and firsthand insights from factory leaders where PowerArena’s AI vision solution has been successfully deployed.

You’ll discover how AI helped overcome common roadblocks in three representative scenarios:

-

In Vietnam, a new network equipment plant adopted automation from its HQ, but output lagged. Was poor training the hidden cause?

-

In Malaysia, a fully automated semiconductor line kept failing at key steps. Could small manual errors risk a brand crisis?

-

In Thailand, EV orders surged, but assembly issues continued to accumulate. Why was scaling so difficult, even with strong demand?

These factories all turned to AI vision to break through human and process limitations.

Turning Point: AI Vision Is More Than Just a Camera

AI vision technology helped these plants transform “human”, the most unpredictable factor, into a measurable and manageable asset.

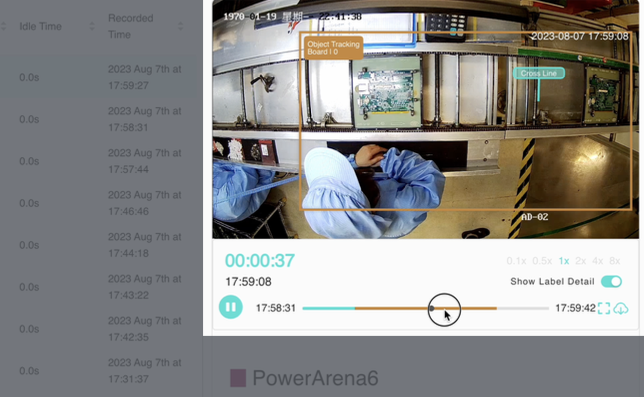

- SOP compliance is monitored in real time, with alerts for deviations

- Root causes traceable via time-stamped video playback

- Visual work instructions derived from HQ best practices

- Remote oversight without the need for costly fly-in managers

Curious How They Did It?

Whether you’re expanding into Southeast Asia or already operating local plants that fall short of HQ performance, this case study offers a clear and practical roadmap for building scalable, AI-enabled operations.

Discover how AI vision can help you overcome talent gaps, cultural differences, and distance—turning every factory into a smart, remotely managed operation.