Global Renowned Semiconductor Manufacturer Improves Product Quality with HOP AI Poka-Yoke

Semiconductor Leader x PowerArena: AI Vision Optimizes SOP, Keeping Yield at 95%

By implementing PowerArena HOP (Human Operation Platform), the average cycle time (CT) for the semiconductor photomask box assembly station was significantly reduced. Yield remains stable at 95%, with a 97.6% first-pass rate, driving precise SOP execution and overall production efficiency.

“HOP provides complete visual data, enabling improvements based on facts, not assumptions.”

— Production Line Manager

Products Features

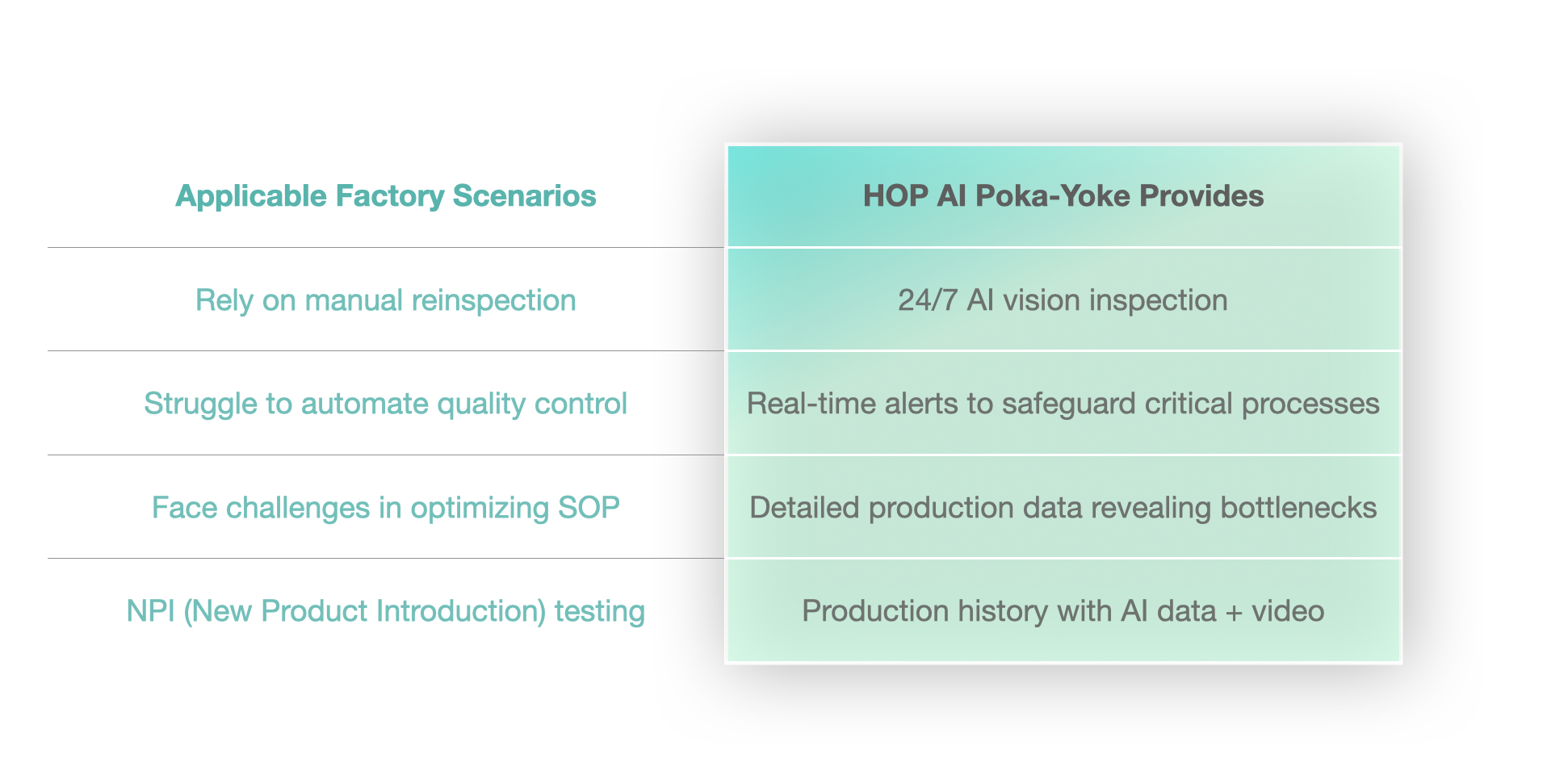

- AI vision for automated SOP management

- Improved production efficiency

- High product yield maintenance

- Enhanced management visibility

Customer Background

This global semiconductor leader has over 25 years of experience in precision manufacturing, producing critical components such as photomask carriers, wafer carriers, and substrate carriers.

To accelerate smart manufacturing, they adopted PowerArena HOP, applying AI vision to manual assembly stations to standardize SOP execution and drive data-based process optimization.

Challenges

- SOP Variability: New hires lack experience, while veteran operators rely on habits, causing inconsistent quality.

- Lack of Data and Visual Evidence: Continuous improvement efforts are difficult to quantify and verify.

- High Training and Allocation Costs: Cross-line support and relearning steps slow production.

Solutions

“We used to rely on experience to identify issues. Now, with video and data, we pinpoint bottlenecks and justify improvements with confidence.”

— Industrial Engineer

1. AI Data Collection and Analysis

Continuous video recording and automated cycle time measurement replace manual stopwatch methods, giving engineers consistent data to reveal process gaps and track improvements.

2. Real-Time AI Alerts

When incorrect steps or abnormal pauses occur, HOP immediately alerts operators and managers, preventing errors from affecting production—a critical feature for yield-focused semiconductor lines.

3. Digital Workstation Guidance

Real-time on-screen guidance helps new operators complete 10–30 assembly steps accurately, reducing training time from half a day to just 2 hours, increasing training efficiency by 4x.

4. Continuous SOP Optimization

HOP enables a detailed review and refinement of SOPs, defining part placements, tool positions, and left/right-hand adjustments. This not only supports AI model recognition but also improves overall process efficiency.

Results

- UPH Increased by 19%: Cycle time reduced from 3.5 minutes to 2.8 minutes, with the fastest cycle achieved in just 1 minute.

- Stable Quality: Yield maintained at 95%, with a 97.6% first-pass rate.

- Higher Management Efficiency: Engineers are freed from repetitive manual timing to focus on process optimization.

“We can now identify production waste in real time and replay footage to trace the root causes—something we couldn’t do before.”

— Industrial Engineer

Download the Full Case Study

Want to see how AI vision and data-driven SOP optimization boost production efficiency?

Managing Semiconductor Processes with AI Vision

PowerArena’s AI vision focuses on optimizing critical workstations in packaging and testing processes, helping factories enhance SOP compliance, reduce human errors, and maintain stable yield rates.

High-value, low-volume products like mask packages face severe challenges in assembly and process management. In cell production workstations, the numerous and complex steps make errors easy to occur. Each operator may be responsible for 10 to 30 assembly steps, and any oversight in a critical step can lead to a significant reduce yield in subsequent processes.

—— Kuei Huang, AI Director at PowerArena. Digitimes..

Explore our semiconductor smart manufacturing solutions and book an AI vision demo today.