Achieve high quality and tighter control with AI Poka Yoke.

Helping human operators to be their best.

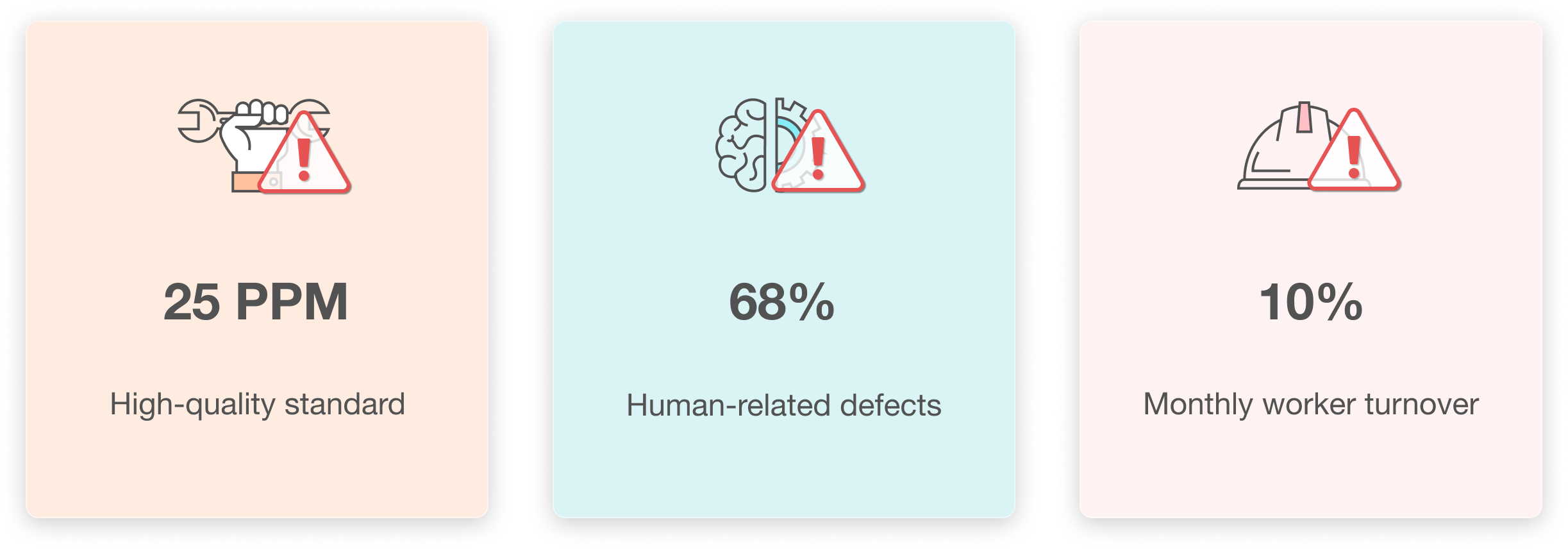

We all make mistakes. According to industry reports, 68% of manufacturing mistakes are human related. Human errors are unpreventable. With more than 10% monthly turn over rate of factory workers.This reality can be expensive when it comes to production lines. Traditional quality control occurs after the product is made. This not only add on the high cost of building and checking the product also essentially made previous works a lost cost.

Introducing

AI Poka Yoke

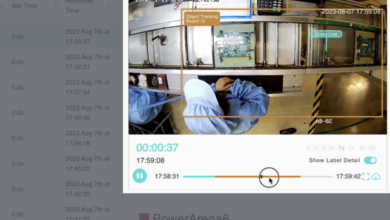

AI IPQC. Realtime Alert. Now with PowerArena Blocks.

HOP AI Poka Yoke oversees the crucial workstations in your assembly line with AI vision. Identifies any error in a work step or deviation from SOP. Now with PowerArena Blocks, customized procedure builder, let user build pre-trained, pre-defined and pre-existing production scenario.

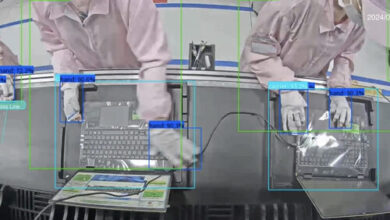

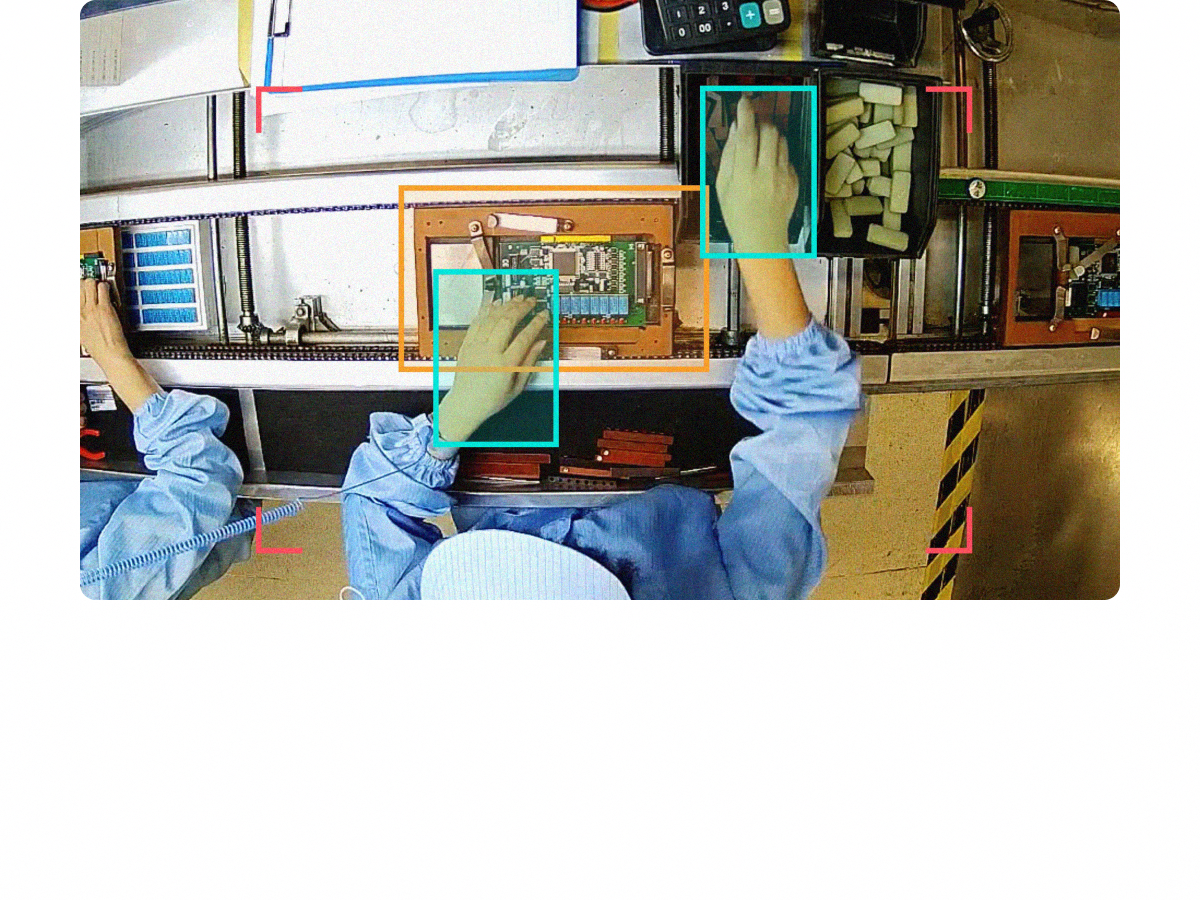

AI Detection of Work Steps & Production Procedures.

HOP AI Poka Yoke oversees the crucial workstations in your assembly line with AI vision. AI Poka Yoke identifies any error in a work step or deviation from SOP. User can also built pre-trained, pre-defined and pre-existing production scenario for their customized production procedures with PowerArena Blocks.

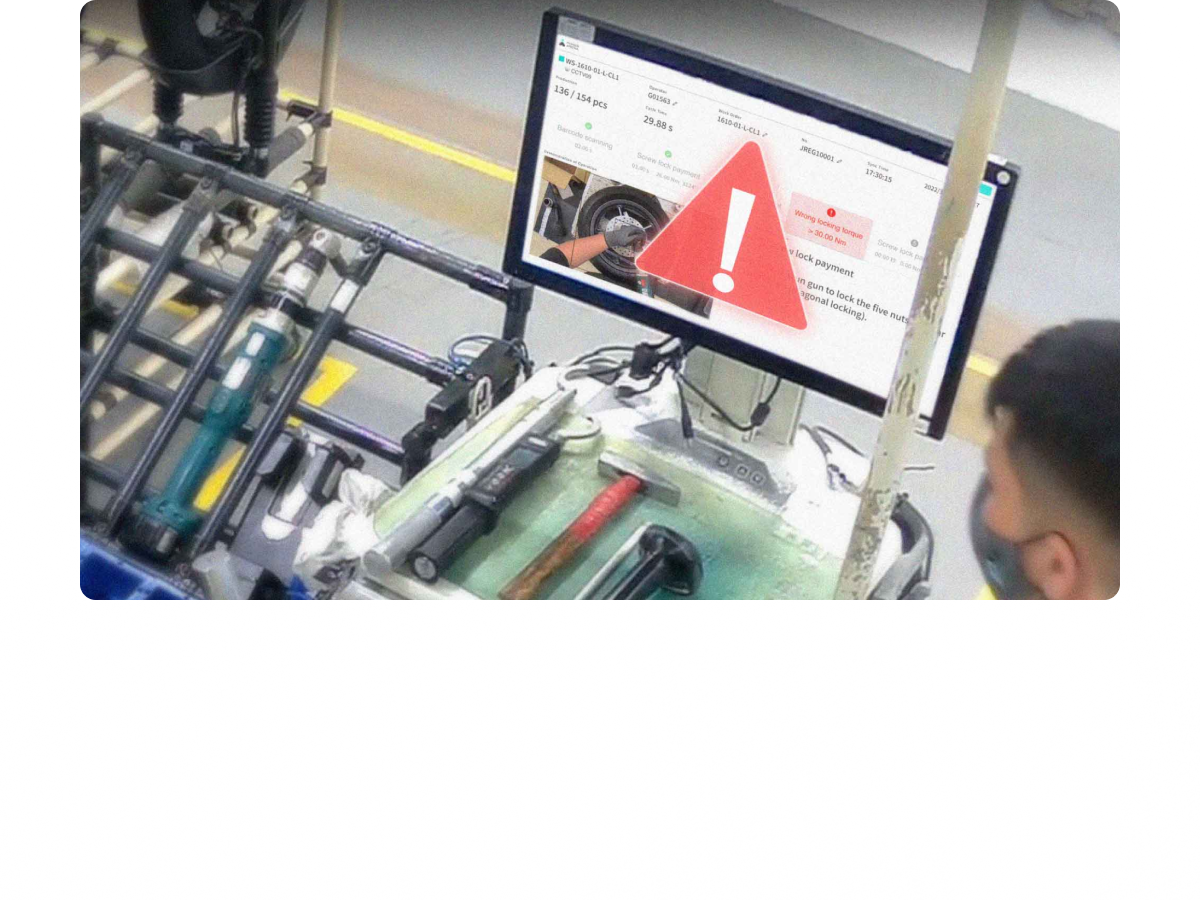

In Process Quality Control with Realtime Alert.

HOP AI Poka Yoke oversees the crucial workstations in your assembly line with AI vision. AI Poka Yoke identifies any error in a work step or deviation from SOP. AI Poka Yoke catches problems as they occur and avoid knock-on effects to ensure top tier production even in the most demanding productions.

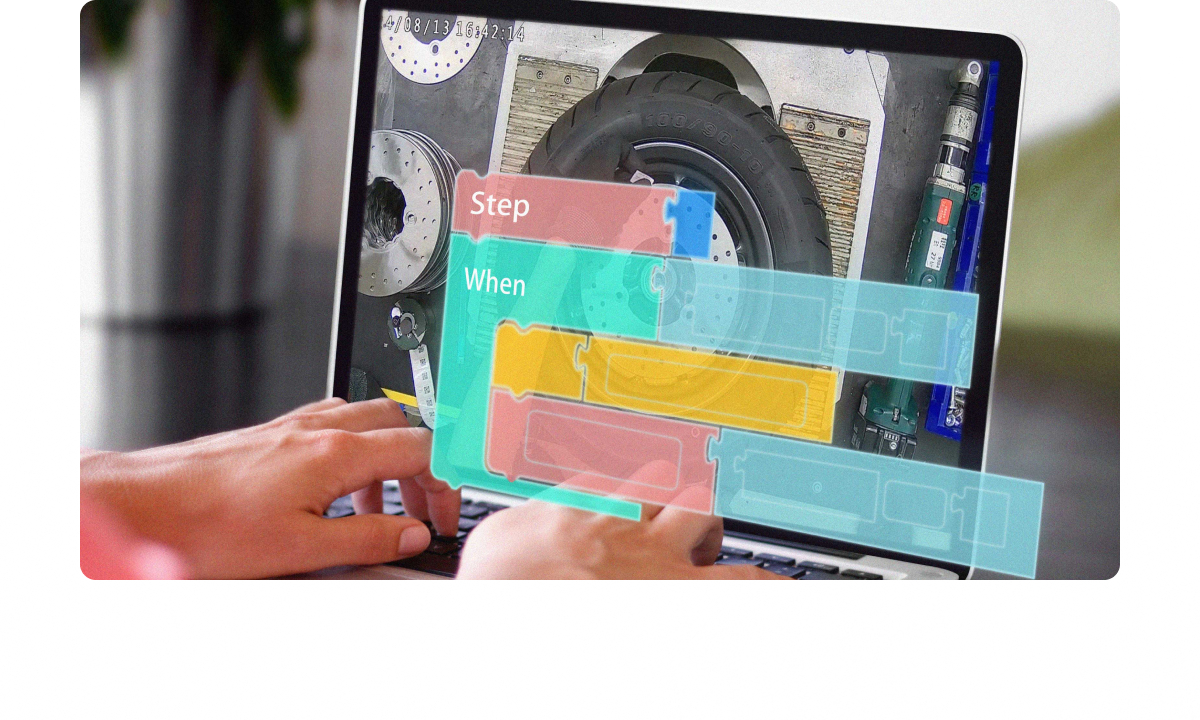

PowerArena Blocks with AI Poka Yoke.

AI Poka Yoke catches problems as they occur and avoid knock-on effects to ensure top tier production even in the most demanding productions. User can now build pre-trained, pre-defined and pre-existing production scenario for their customized production procedures with PowerArena Blocks.

HOP AI Poka Yoke

Case Studies

PowerArena HOP has already delivered impressive ROI in a factory similar to yours

These case studies cover only a fraction of PowerArena HOP installations. Tell us about your situation and we’ll share relevant data and details.

Main Applications

DIGITAL STATION – TRACEABLE

DIGITAL STATION – TRACEABLE

- HOP consolidates shop floor data via integrated IoT sensors, video cameras and MES to roll back time.

- Shop floor reporting via HOP video recording activity at the station and assigning a serial number to each product.

- Video can be searched by serial number. The assembly of any item can be readily seen at any time.

- You own your data and it can stay on-premise.

Read more

AI LINE BALANCING – ACTIONABLE

AI LINE BALANCING – ACTIONABLE

- HOP AI vision records line activity and analyzes cycle times so you can increase line productivity.

- Shop floor visibility via AI video and IoT cycle time data collected 24/7. Visualizing your operation was never easier.

- Identify issues like production line blockages or equipment malfunction in real time. This helps reduce downtime and improves overall efficiency.

- Drive productivity improvement from AI line balancing applying cycle time data to perform root cause analysis.

Read more

AI POKA YOKE – PREVENTABLE

AI POKA YOKE – PREVENTABLE

- Catch problems as they occur and avoid knock-on effects caused by human operators in the production line.

- AI work step detection and dynamic work instructions allow factories to tailor existing systems for 100% quality control.

- Prevent defects at the source by comparing the current production to a known standard set with real time alerts of potential problems.

- Flexible and adaptable HOP system can learn and integrate with your production environment.

Read more