A giant leap for manual operation understanding.

PowerArena Human Operation Platform (HOP) powered by AI vision delivers real value.

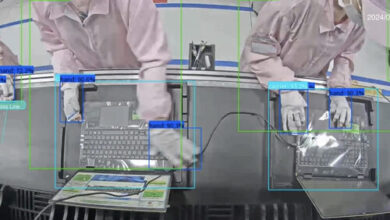

Time and motion study.

Engineers closely observe assembly lines to discover inefficiencies in manual operations. This means calculating cycle times or tracking specific work steps.

Such time and motion studies are expensive, time consuming and only apply to a brief period of time. Human bias also limits its value.

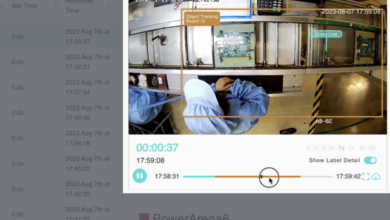

MES tells you what, but HOP tells you why.

Your MES may tell you production dropped 10% on Wednesday – but it won’t tell you why.

With Human Operation Platform you can learn exactly why you lost that production.

Achieve lasting productivity and quality solutions with PowerArena.

Your Arena. In full Control.

PowerArena’s HOP ensures more accurate forecasting, projection, and budgeting, enabling manufacturers to plan with greater precision. This leads to fewer errors and higher quality unit output, directly impacting overall efficiency.

Data Integrity on Day One.

With full traceability in manufacturing. HOP backed your production data based on what’s really happening in real time. This transparency enhances product quality and builds stronger customer trust.

Build Your Golden Line. Then Scale.

Eliminating factory bottlenecks and simplifying SOP golden line development and replication are crucial. These advancements streamline production processes, making it easier to scale operations efficiently and consistently.

Relief for your pain points

Main applications

Digital

Station

Digital Station

- Reduce downtime

- Monitor the interaction between workers and machines

- Detect long delay and assist root cause analysis

- Improve machines overall equipment effectiveness (OEE)

AI Line

Balancing

AI Line Balancing

- Streamline workflow productivity

- Identify opaque and complex bottlenecks

- Workflow metrics that visualize the factory floor

- Empower the workforce by strengthening teamwork and gaining productivity

AI

Poka Yoke

AI Poka Yoke

- Maintain standard operating procedure compliance

- Detect and alert workers who skipped work steps

- Ensure quality through SOP compliance

- Customizable SOP detection software

Case Studies

PowerArena HOP has already delivered impressive ROI in a factory similar to yours

These case studies cover only a fraction of PowerArena HOP installations. Tell us about your situation and we’ll share relevant data and details.