By Sursha Wu

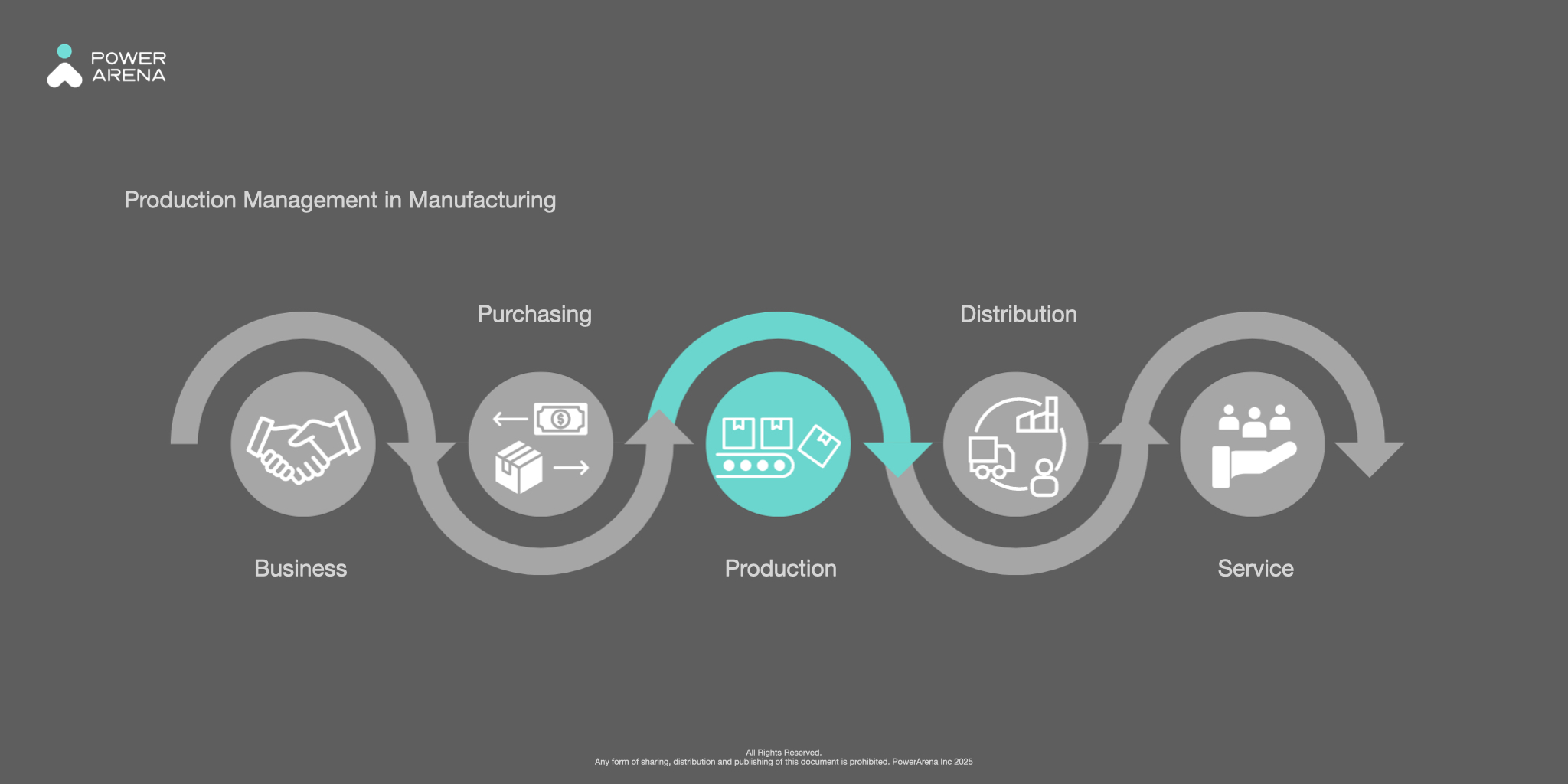

What is Production Management?

Production management involves effective planning of resources used in manufacturing. The goal is to improve operational efficiency, ensure timely product completion, and achieve quality and cost objectives. Production management covers scheduling, production execution, and quality control, forming a core component of smooth manufacturing operations.

Complex management tasks are crucial in manufacturing activities. Reference: https://www.youtube.com/watch?v=TlUUmgyteUE

Objectives of Production Management

Maximizing Profitability with QCD and PDCA

The main goal of production management is to build efficient manufacturing and sales workflows to maximize profits.

Businesses often use the QCD (Quality, Cost, Delivery) system to offer high-quality products at low cost with quick delivery.

To replicate successful production processes, management frequently adopts the PDCA (Plan, Do, Check, Act) cycle to rapidly test and resolve production issues.

Plan:

Analyze market demands and internal resources to set improvement goals and plans, including capacity planning and resource allocation.

Do:

Execute the production plan with on-site management and real-time feedback.

Check:

Compare outcomes with targets using data to evaluate line efficiency, product quality, and delivery performance.

Act:

Adjust and continuously improve processes based on evaluation results.

Principles of Production Management

The 4M1E (Man, Machine, Material, Method, Environment) principle is essential for stable, high-quality, and efficient manufacturing.

4M1E Components:

Man:

Proper staffing and ensuring SOP adherence are critical. AI vision technology can track workers’ operations in real-time, ensuring SOP compliance and quantifying efficiency.

Machine:

Regular equipment maintenance, calibration, and upgrades reduce downtime. Many factories use predictive maintenance via sensors and data analytics.

Material:

Materials must undergo strict engineering validation and maintain stable supply. AOI (Automated Optical Inspection) replaces manual inspections, accurately identifying defects and improving quality.

Method:

Industrial engineers (IE) must create practical and easy-to-follow SOPs based on real operational needs. Clear and standardized steps improve consistency and efficiency on the line.

To do this well, engineers need a deep understanding of actual shop floor conditions—common issues, workflow bottlenecks, and operator habits. Traditionally, this relies on long hours of observation, which can be inaccurate due to on-site variation.

With AI vision, this process becomes faster and more accurate. The system records and analyzes real production behavior in real time, giving engineers a full picture of line operations. Combined with tools like FMEA, AI vision helps improve quality control and reduce risk.

Environment:

Maintaining optimal temperature, humidity, cleanliness, and lighting is critical. Safety management includes clear routes, signage, and emergency equipment. Many factories now use environmental monitoring systems and electronic fences.

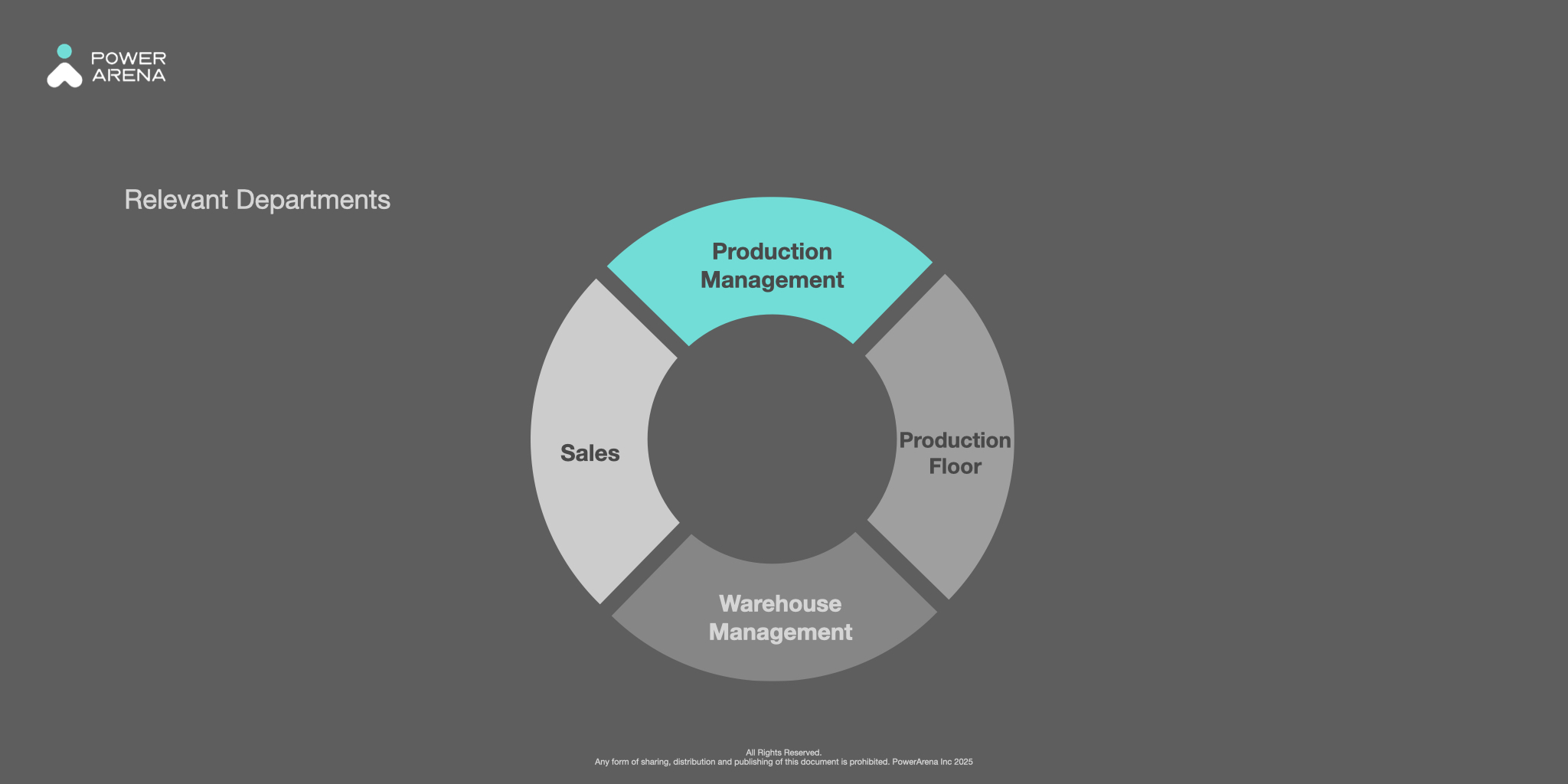

Departments Involved in Production Management

Effective production management requires cross-department collaboration. Reference: https://www.youtube.com/watch?v=TlUUmgyteUE

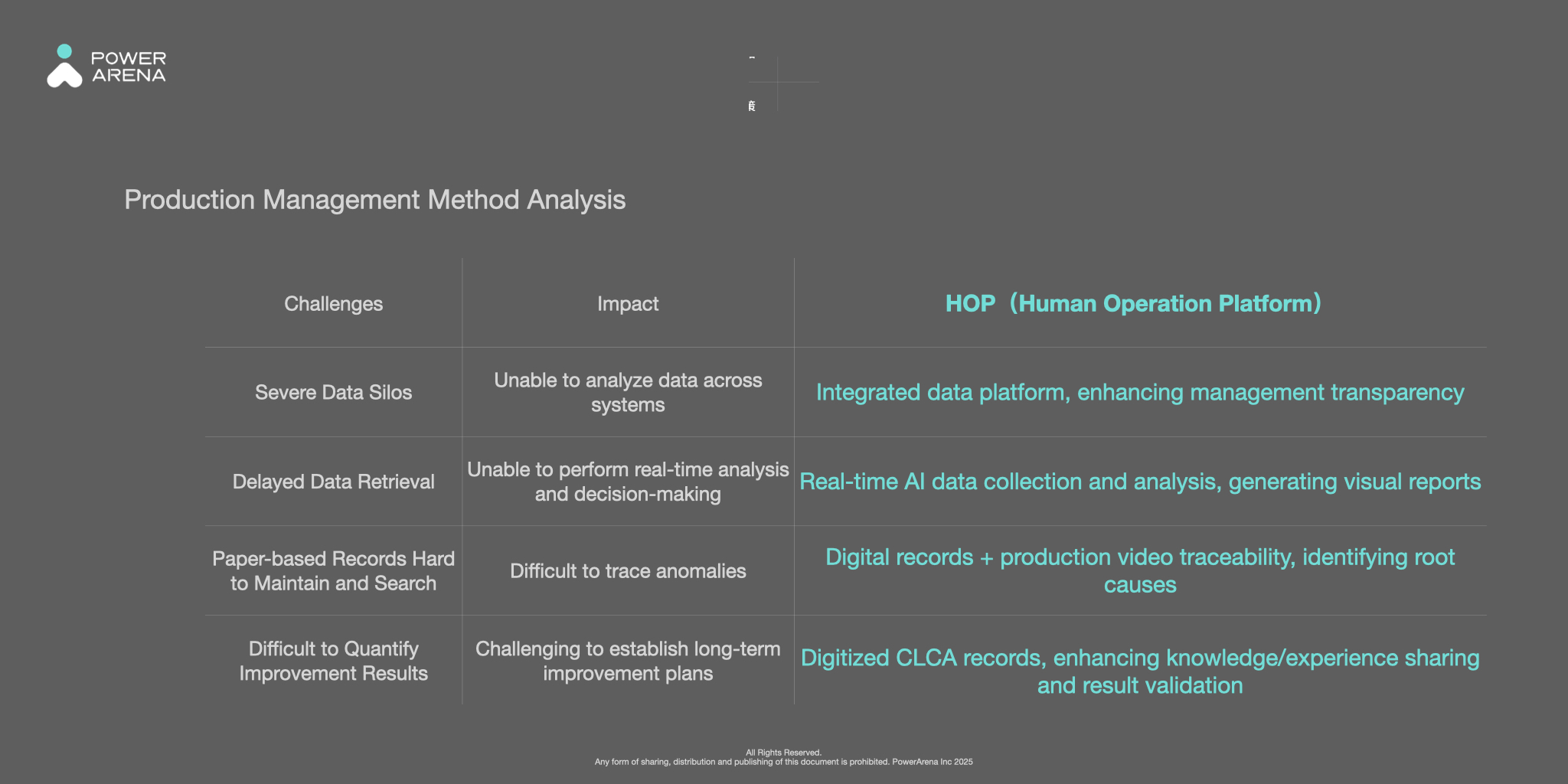

Challenges in Production Management

Common tools like manual record-keeping and on-site inspections create challenges for implementing improvement plans.

HOP(Human Operation Platform)addresses multiple production management challenges.

Case 1: Time Lost to Manual Data Work

At one electronics factory, a production manager spent hours every day collecting and comparing paper records, Excel files, and verbal updates. He needed to compile production reports manually.

The data was messy and inconsistent. He once missed a line issue that delayed delivery. Although automation was possible, the plant’s data was too scattered and manual.

Download the Case study: More Than Just Data Analysis – AI Prevents Production Issues

Case 2: Hard to Access Real-Time Production Info

At an automotive electronics plant, a manager received a sudden request to deliver an urgent order a month early. He had to reschedule immediately and check line capacity.

He tried calling each team, but got no clear updates. Therefore, he had no choice but to walk the floor to gather data, such as cycle time, idle time, and lead time manually. All the process took all morning.

Two weeks later, a new team took over the line. Productivity dropped, and previous data no longer reflected actual performance. He had to start over.

The manager also noted that without a digital system, they couldn’t confirm if frontline leads enforced SOPs or if reported data was accurate. The lack of real-time, transparent information slowed decisions and added uncertainty to production management.

Case 3: No Digital Record of Improvements

A laptop OEM improved delivery speed by optimizing steps and adjusting work schedules at key stations. Efficiency rose by 10%.

Six months later, production hit another bottleneck. The original engineer had left, and the new manager couldn’t find past records, methods, or data. Without a full picture, the team couldn’t repeat the improvements and missed the chance to replicate a successful line.

Customer Success: Closing the Blind Spot with HOP

In the past, production teams relied on manual reports and on-site checks. The data was often delayed and incomplete.

This lack of real-time insight left managers in a blind spot—unable to respond quickly when issues arose. Without timely data or smooth communication, small problems grew into bigger ones.

To solve this, manufacturers partnered with PowerArena and deployed the HOP (Human Operation Platform).

With AI at the core, HOP transformed how factories manage production and closed critical visibility gaps.

AI Vision: 24/7 Production Data Collection for Real-Time Insights

HOP (Human Operation Platform) uses AI vision to automatically collect and analyze production data. It accurately tracks cycle time, process time, and idle time, then turns the data into visual reports in real time.

This reduces the manual workload and helps managers quickly understand what’s happening and identify root causes.

Also, HOP is an integrated digital platform. All departments can view consistent, objective production data from one system. This eliminates information gaps between teams and improves cross-department collaboration—bringing full digitization and transparency to production management.

Real-Time Quality Control with 100% Transparency

HOP (Human Operation Platform) uses AI vision to track operator behavior in real time, ensuring every step follows SOPs. Cameras on the line capture the full process and detect errors in the producing process.

When the system spots a potential issue, it triggers alerts and stops the station—preventing defects from moving forward. It also generates reports showing where and why problems occurred. Managers can decide quickly whether to continue or fix the issue.

Most importantly, this consistent and objective information is shared across departments and management levels. It improves transparency and builds trust while giving teams the data they need to improve SOPs and workflows.

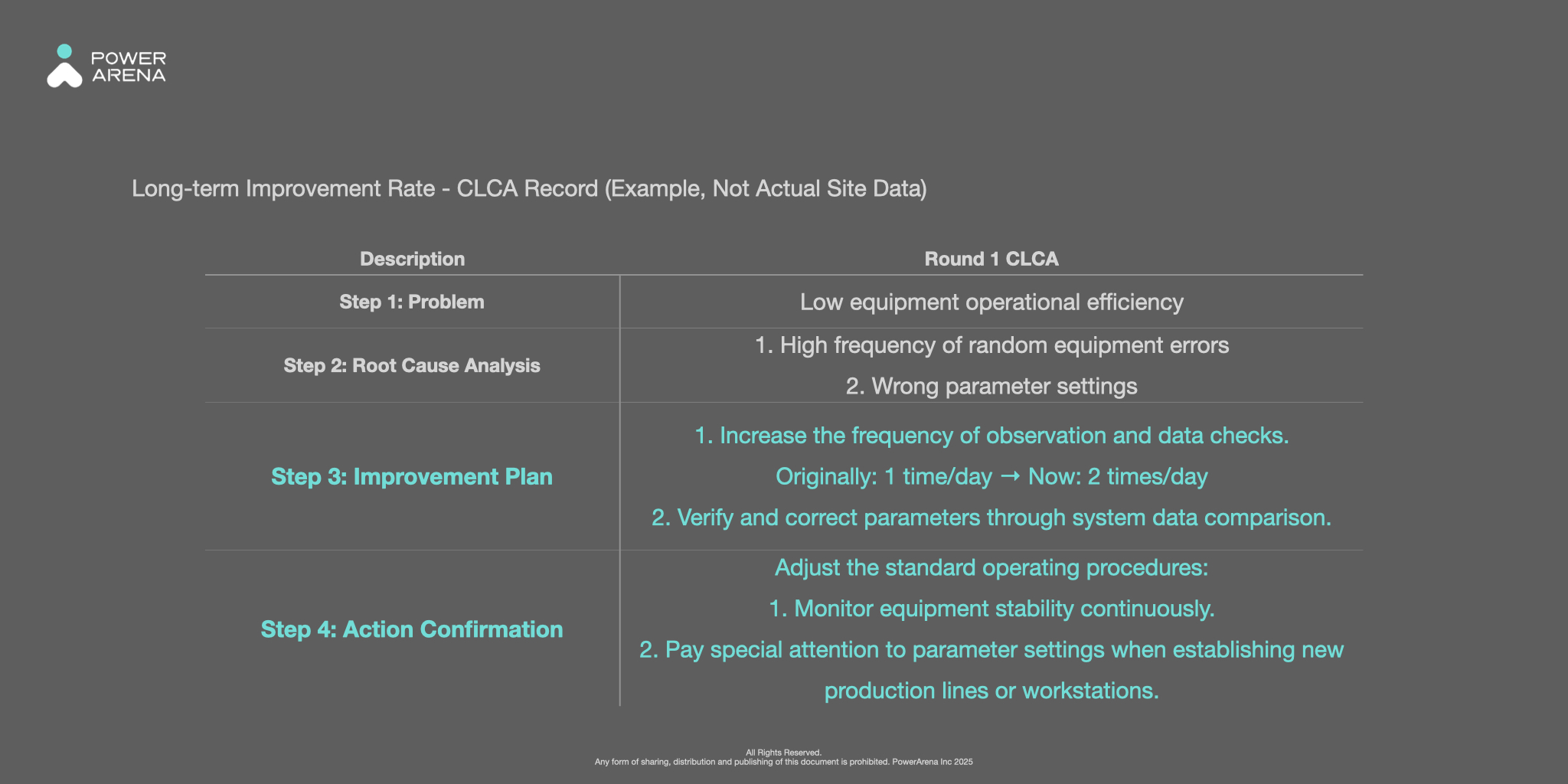

CLCA: Building a Repeatable, Long-Term Improvement Process

The factory used HOP’s CLCA feature to document all line improvements.

HOP’s CLCA (Closed Loop Corrective Action) feature helps factories record improvement plans in a structured way. These records serve as both a reference for process fixes and a foundation for standardizing future operations.

For example, one factory faced long-term line imbalance. Using HOP’s video data, they traced the root cause to equipment issues and incorrect settings. The team responded with a clear plan:

-

Increase inspection frequency to four times per day

-

Adjust and optimize parameters, then log the changes in HOP

Other managers can now follow the same steps to solve similar problems. With continuous data collection and analysis, HOP helps verify results and drive ongoing performance improvements.

Table of Contents