AI Vision Creates EV Manufacturer’s Production Line for Human-Machine Collaboration

How EV Manufacturer Achieved Zero Defects with AI Vision

“How can I improve quality control in my smart factory?”

“What’s the best way to track SOP compliance in real time?”

“How can I prevent defects before products leave the assembly line?”

These questions reflect common considerations and challenges that arise after initial automation is in place, particularly when factories pursue further digital transformation or encounter bottlenecks in process and quality management.

Background

A global electric vehicle (EV) manufacturer had invested heavily in automation, creating what appeared to be a model smart factory. MES tracked production digitally, AGVs kept materials moving without delay, and IoT-connected tools recorded critical process data…

The Blind Spot: Human Actions

Beneath the factory’s high-tech systems was one critical gap: the human factor. The MES could track every machine movement, but it could not confirm whether operators followed the correct sequence, used the right tools, or skipped steps entirely.

These deviations, including missed SOP steps, out-of-order work, and unrecorded tool use, often went unnoticed until they appeared as costly defects during inspections or, even worse, after products reached customers.

Their challenge was simple but critical:

How to close the human-data gap and capture every action on the line as it really happens.

The Turning Point: AI Vision for Human Operation Monitoring

Download the Case Study to See the Full Results

This globally renowned electric vehicle manufacturer has implemented PowerArena’s HOP (Human Operation Platform) to enhance process management in vehicle assembly.

With HOP, the factory achieved:

/24/7 workstation monitoring with AI vision — no more reliance on manual observation

/Real-time SOP deviation alerts — catching missed steps, wrong tool usage, or incorrect sequences instantly

/Image-based cycle time tracking — exposing discrepancies between MES logs and reality

/Instant stoppage for high-risk errors — preventing defective products from leaving the station

/100% first-pass yield — zero defective scooters shipped

From Reactive Fixes to AI-Driven Prevention

Before AI vision:

- Problems were found after products shipped, leading to costly rework, warranty claims, and safety risks.

- Root cause analysis relied on partial MES data and staff recollection.

After AI vision:

- Every workstation action became visible and verifiable.

- Managers could trace any production moment through instant video backtracking.

- Quality issues were stopped at the source — before they became defects.

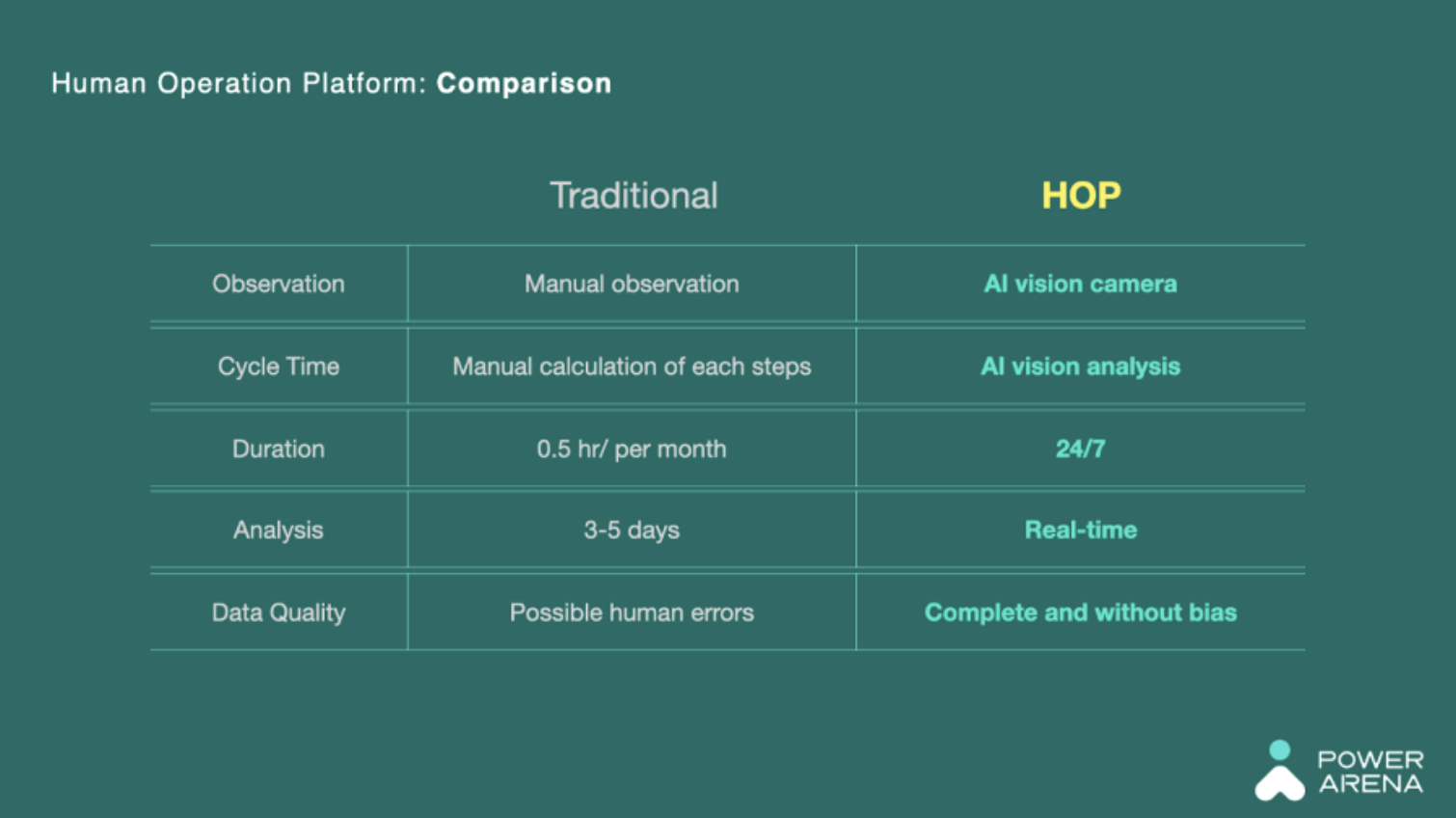

AI vision fills the information gap in production operations. It replaces manual monitoring with objective, 24/7 and complete cycle time collection through real-time video analysis. This

eliminates the possibility of human operator measurement errors.

This Case Study Is Perfect If You’ve Ever Asked:

- “How can I reduce human error in production?”

- “What’s the most effective quality control method for EV or automotive assembly lines?”

- “How can I improve yield in high-mix, high-changeover manufacturing?”

- “How do I digitize manual processes in my smart factory?”

- “What’s the best AI solution for process quality control?”

Discover how this leading electric scooter manufacturer integrated the Human Operation Platform (HOP) with its existing MES and AGV process control systems to build an AI production management solution designed to ensure zero defects on the line.

PowerArena Human Operation Platform (HOP) is an AI-driven smart manufacturing solution that visualizes production and provides real-time, transparent information for labour-intensive production lines.