Compal Integrates HOP and LLM to Enhance Production Line Management Efficiency

Background

As a Fortune 500 global ODM leader, Compal is not only focusing on AI technologies but also accelerating its smart factory transformation. To enhance production line management and decision-making, Compal partnered with PowerArena HOP (Human Operation Platform), integrating AI vision and LLM technologies to build a complete human-driven production data foundation and a production management large language model.

Challenges

- Traditional manual inspections and sampling cannot fully capture operator behavior, making root cause analysis difficult.

- Lack of real-time, structured data impacts efficiency and quality decisions.

- SQL-based queries are complex, making cross-department collaboration and quick insights challenging.

Solutions

1. AI Vision + Visual Production Records

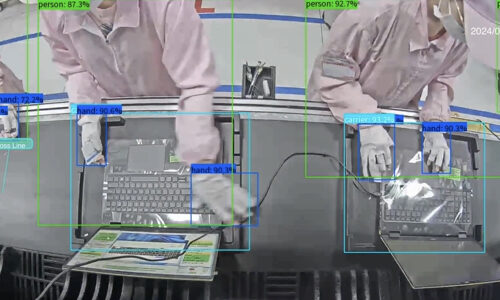

PowerArena deploys cameras across production lines to record operator activities 24/7, creating comprehensive production records. Unstructured video data is processed through AI vision to generate structured metrics like cycle times, anomalies, and workstation details.

2. LLM (AI Chatbot) for Smart Queries

Compal built an internal LLM powered by data from PowerArena HOP. Managers can query production status using natural language and receive instant, accurate insights.

3. Real-Time Data Visualization

All anomalies, timestamps, and workstation data are traceable, providing real-time insights for process optimization and bottleneck analysis.

Tap CC for Caption

Results

- Higher Productivity: Automated data collection and analysis reduced troubleshooting time for engineers.

- Smarter Decisions: LLM + HOP enables management to gain full production insights through natural language queries.

- High-Value Data Foundation: Supports future AI-driven production optimization and smart factory initiatives.

Future Outlook

Compal will continue expanding LLM applications in production management, leveraging its complete production dataset to drive broader smart manufacturing scenarios and strengthen its global competitiveness.

Download Full Case Study

Want to learn more about how AI vision and LLM boost production efficiency and decision-making?

Interested in LLM and AI Agents for Manufacturing?

If you want to explore how AI Agents and LLM can optimize smart factory workflows,