By Sursha Wu

Southeast Asia is an increasingly important manufacturing hub, offering competitive labor costs, a strategic location, and political stability.

Yet for many manufacturers, operating in the region brings unexpected challenges.

Factories in Vietnam, Thailand, and Malaysia often face labor instability, limited engineering support, and a lack of systems to ensure consistent quality and efficiency—leading to performance gaps compared to parent factories in Taiwan or China.

Before companies can fully benefit from the advantages of Southeast Asia, they must first overcome hidden operational hurdles.

This case study draws from our hands-on experience working with factories across the region. We’ve helped address labor and quality challenges by implementing AI vision systems that improve visibility, standardize processes, and enable better control.

Whether you’re planning to expand into Southeast Asia or already operating factories there, this article offers practical solutions to help you regain control, streamline operations, and scale with confidence.

How AI Vision works in Southeast Asia Factory

1. Real-Time SOP Compliance and Defect Prevention

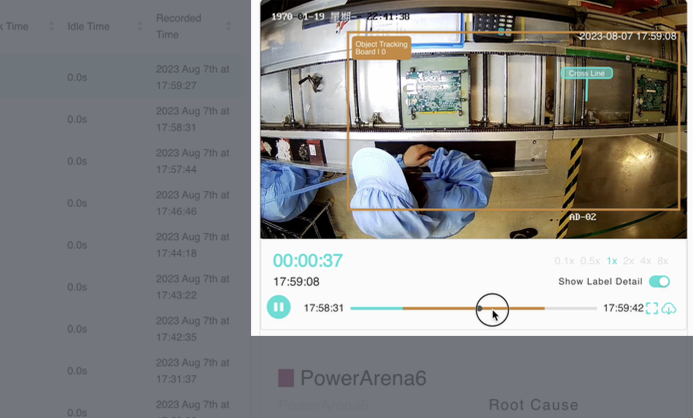

Situations like leaving the workstation or exceeding standard working time are automatically flagged and reported to the line manager by the system. (Reference clip from Compal’s demo line)

AI vision system precisely identifies people, tools, and materials on the line, continuously monitoring operator actions against standard operating procedures (SOPs).

If steps are missed or done out of sequence, the system immediately alerts managers—allowing them to step in and correct issues before they escalate.

At critical workstations, this real-time visibility, combined with AI error prevention, helps managers catch mistakes as they happen, especially when the line is staffed with new or inexperienced workers. It significantly reduces the risk of unnoticed errors, minimizes rework, and ensures quality and efficiency are maintained throughout production.

2. Worker Condition Insights Through Visual Data

AI vision goes beyond what traditional MES or IoT systems can deliver.

By combining visual data with production system integration, it provides a comprehensive, contextual view of both worker actions and their environment—something existing systems alone cannot achieve.

This allows managers to visually trace the root causes of issues, such as fatigue, distraction, or workflow mismatches—factors often overlooked in conventional reporting.

These insights empower teams to make informed adjustments to SOPs, training protocols, and workstation design, ultimately improving both operator performance and overall line stability.

3. Digitizing Operational Know-how

AI vision also plays a key role in capturing how experienced operators perform critical tasks. By turning routine execution into structured digital records, manufacturers can preserve frontline expertise and convert it into scalable training materials. This ensures best practices are no longer siloed but can be shared and applied consistently across sites—supporting workforce development and standardization efforts.

Success Cases: AI Vision in Practice

EMS Factory in Vietnam

A network device assembly plant in Bắc Ninh faced a significant performance gap.

Despite investments in new equipment and a well-planned layout, productivity remained 20–30% lower than at comparable facilities in China.

The root cause? Daily production issues couldn’t be systematically tracked or resolved.

Managers in Vietnam had to rely on guesswork—or depend on more experienced counterparts in China frequent site visits to help the Vietnam factories solve the problems. This approach delivered little actual improvement.

That changed with the introduction of AI vision.

AI vision played a key role in digitizing expertise.

- Visual training modules:By capturing the precise motions and timing of top-performing operators in China, the system created visual training modules that helped Vietnamese teams quickly adopt best practices.

- Recorded fixes and process adjustments:Managers could record fixes and adjustments, making it easier to share improvements across teams and factory sites. This transformed continuous improvement into a company-wide effort instead of a site-specific initiative.

- Real-time operational visibility:With integrated video and data analysis, AI vision provided managers with real-time visibility into operations. They could review footage, monitor cycle times, and track station-level productivity — enabling faster validation of improvements and quicker decision-making.

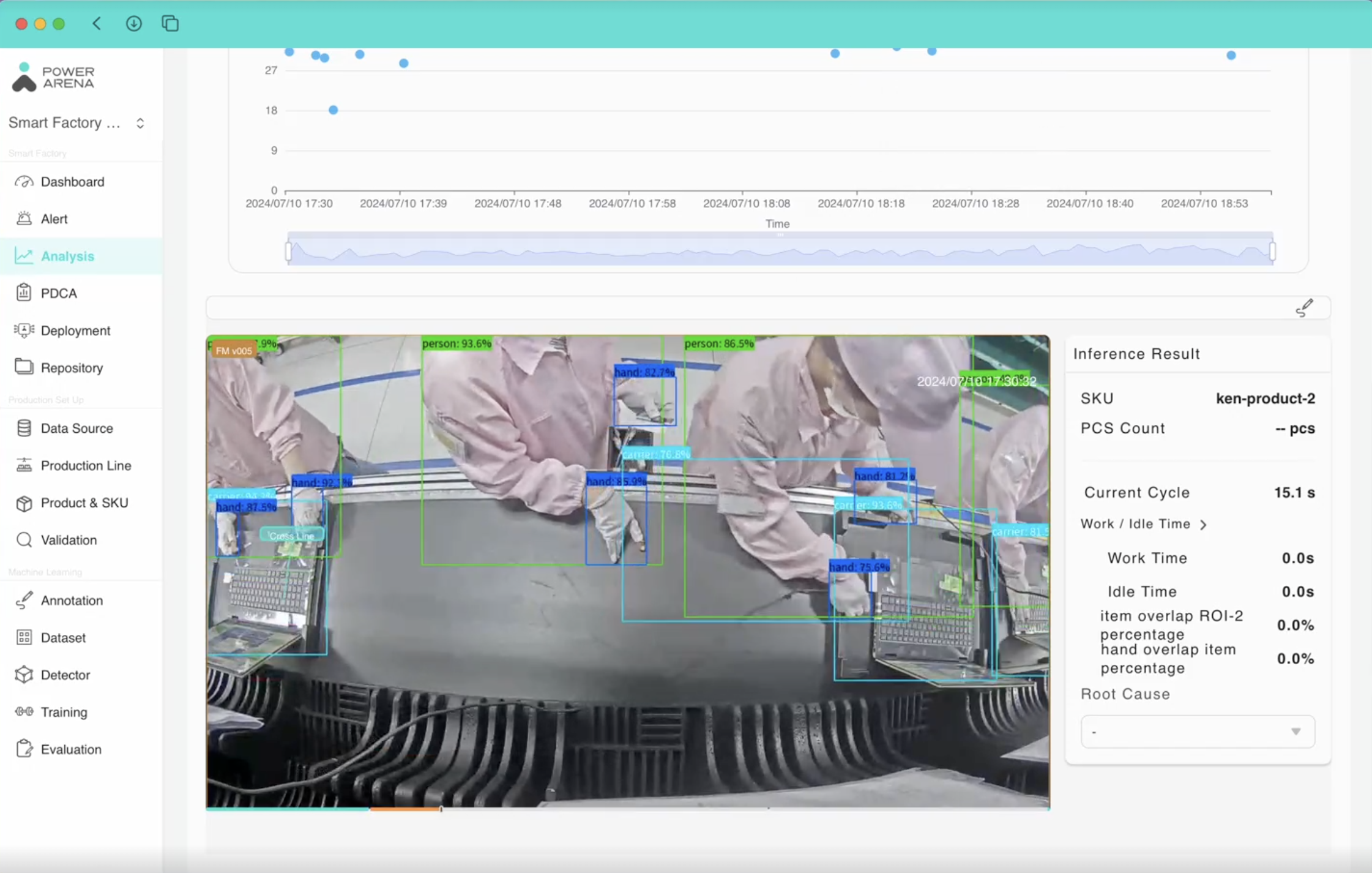

HOP (Human Operation Platform) supports CLCA features for line improvement plan.

Semiconductor Factory in Malaysia

At an OSAT facility in Penang producing automotive-grade ICs, recurring quality issues were tied to manual steps—especially wafer handling, labeling, and packaging.

Despite high automation levels, these human-involved processes remained critical, yet difficult to monitor.

Wafer mishandling during transfer introduced micro-damage that reduced yield. Misplaced barcodes broke traceability and led to customer rejections. Manual steps during sealing or inspection were sometimes skipped, resulting in defects that were hard to trace back.

To gain visibility and control, the factory implemented AI vision for automated production management:

- Real-time monitoring and risk prevention:AI vision tracked operator actions in real time, flagging improper movements, skipped steps, and risky behaviors like incorrect wafer handling or label placement—enabling immediate correction before issues escalated.

- Visualized, traceable data for better decisions:Every action was time-stamped and recorded, turning manual processes into visual, traceable data. This allowed teams to quickly review incidents, validate SOP compliance, and shift from guesswork to data-driven decision-making.

AI vision is the only solution which can automatically ensure SOP compliance and achieve real-time error prevention in manual production line.

Electric Vehicle Factory in Thailand

Thailand is quickly positioning itself as a regional hub for electric vehicle (EV) manufacturing, driven by the government’s EV3.5 policy and strategic infrastructure investments.

However, many local factories face challenges: limited management structures and a lack of real-time operational visibility…

HOP(Human Operation Platform)for Sustainable Excellence

HOP (Human Operation Platform) Dashboard

PowerArena’s HOP (Human Operation Platform) leverages AI vision technology to digitize and optimize labor-intensive production lines, enabling smarter, more efficient operations.

Key Features

- Real-time SOP compliance powered by continuous production video capture and behavior analysis

- Full operational transparency with on-demand traceability and historical video playback

- 24/7 production data collection to support process optimization and informed, data-driven decisions

Conclusion: Building Smart Factories with Smart Management

Automated Production Oversight

If AI can handle data collection and analysis, there’s no reason to rely on manual effort.

HOP (Human Operation Platform) enables real-time oversight by capturing accurate cycle and idle times at each station—data that’s difficult to obtain manually. Operators follow clear on-screen instructions, while supervisors monitor live footage to spot inefficiencies or disruptions.

With objective, video-based insights, managers can act faster and more precisely. This shift from reactive to proactive management is key to building truly smart, optimized factories.

Remote, Real-Time Management

For many factories in Southeast Asia—whether local or part of a regional network—on-site visibility remains limited, especially when cross-border teams face language and cultural barriers.

HOP (Human Operation Platform) bridges that gap by providing a digital window into frontline operations. Instead of relying on occasional site visits, managers can now remotely monitor live conditions, track key metrics, and respond to issues as they arise. With real-time video and data, decisions are grounded in facts—not assumptions—enabling faster problem-solving and more consistent performance across regions.

Replicating High-Performing Lines

Expanding from China into Southeast Asia often exposes a critical gap: how to replicate proven production lines. Without a structured way to transfer frontline expertise, performance drops and ramp-up takes longer.

HOP (Human Operation Platform) addresses this by capturing not just data, but actual task execution—from how top operators move to how they solve problems. These recordings become visual SOPs and reusable training modules, helping teams in new sites adopt best practices quickly and consistently.

With HOP, operational excellence becomes scalable—making it easier to maintain quality, reduce onboarding time, and bring new sites online with confidence.

Table of Contents